Anti-seepage underground pipeline structure in soft soil matrix and construction technology of anti-seepage underground pipeline structure

An underground pipeline and construction technology technology, applied in the direction of pipeline laying and maintenance, pipes, branch pipelines, etc., can solve the problems of unstable road foundation, floating and bending pipelines, troublesome maintenance, etc., to improve the use effect and service life, improve Stability and tightness, the effect of reducing the probability of maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] Below in conjunction with accompanying drawing, the present invention will be further described:

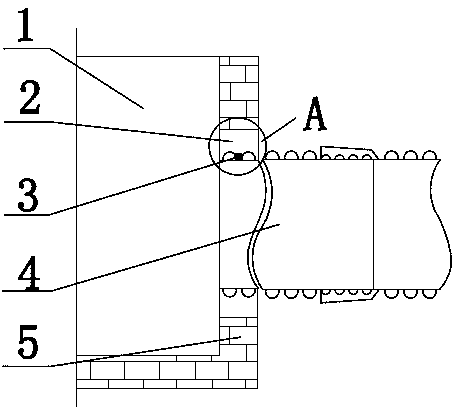

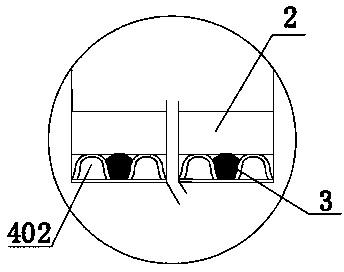

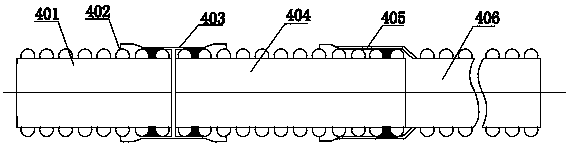

[0036] Such as Figure 1-3 As shown, an anti-leakage underground pipeline structure in a soft soil matrix includes an inspection well 1 and an HDPE pipeline 4. A connection hole 101 is provided on the well wall 5 of the inspection well 1, and an installation collar is closely arranged on the connection hole 101. 2. The installation collar 2 is a concrete structure collar. The inner diameter of the installation collar 2 is 3-5mm larger than the maximum outer diameter of the HDPE pipe 4. The installation collar 2 depends on the actual situation and needs to be used in the section with a higher groundwater level. , the section with a lower groundwater level may not be used; the HDPE pipe 4 is plugged and arranged on the installation collar 2, and a sealing ring 3 is arranged between the HDPE pipe 4 and the installation collar 2, and the HDPE pipe 4 is segmented structure, whic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com