A cold end heat exchanger for a Stirling refrigerator

A cold-end heat exchanger and refrigerator technology, applied in refrigerators, refrigeration and liquefaction, compressors, etc., can solve the problems of insignificant improvement of heat exchange effect and low thermal conductivity, and achieve the elimination of contact thermal resistance and heat exchange. The effect of increasing the area and increasing the cooling capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with accompanying drawing:

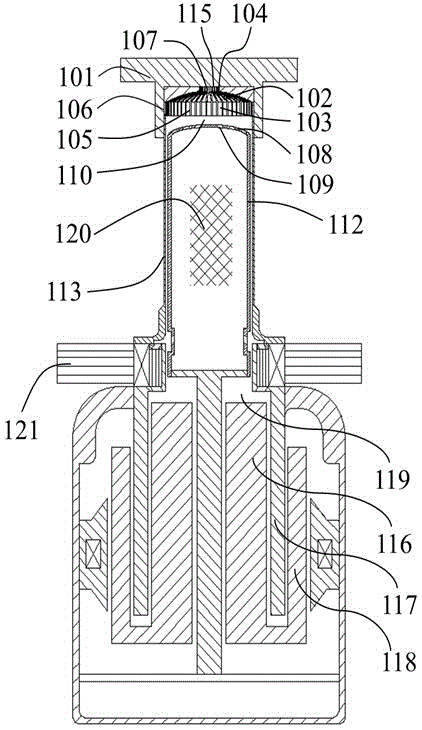

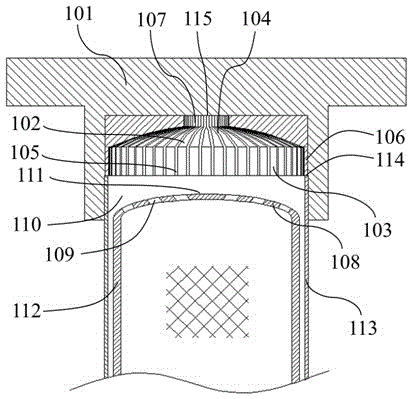

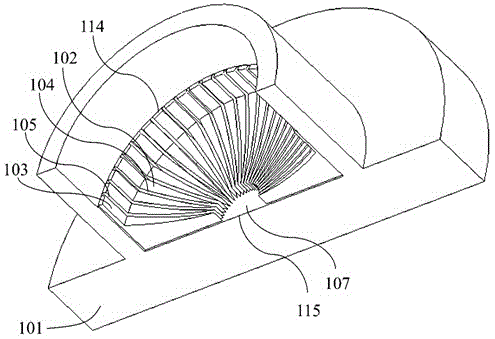

[0023] Such as Figure 1-Figure 4 A cold end heat exchanger for a Stirling refrigerator is shown, including a cold head 101, a regenerator air outlet cover 108, a regenerator air outlet 109 arranged on the regenerator air outlet cover 108 and The expansion cavity 110 , the cold head includes a cold head inner top surface 102 and a cold head inner wall surface 103 . The cold head 101 of the Stirling refrigerator according to the present invention adopts high thermal conductivity material copper. Both the inner top surface 102 of the cold head and the outer top surface 111 of the gas outlet end cover of the regenerator adopt a dome structure, and the shapes of the two are consistent. A plurality of evenly distributed top slits 104 are opened on the inner top surface 102 of the cold head, and a plurality of evenly distributed wall slits 105 are opened on the inner wall surfa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com