Rotation angle measuring method, device, system and engineering machine

A technology of rotation angle and measurement system, applied in the field of construction machinery measurement and control, and rotation angle measurement, can solve the problems of limited number of induction pulses and low detection accuracy, and achieve the effect of improved detection accuracy and precise control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

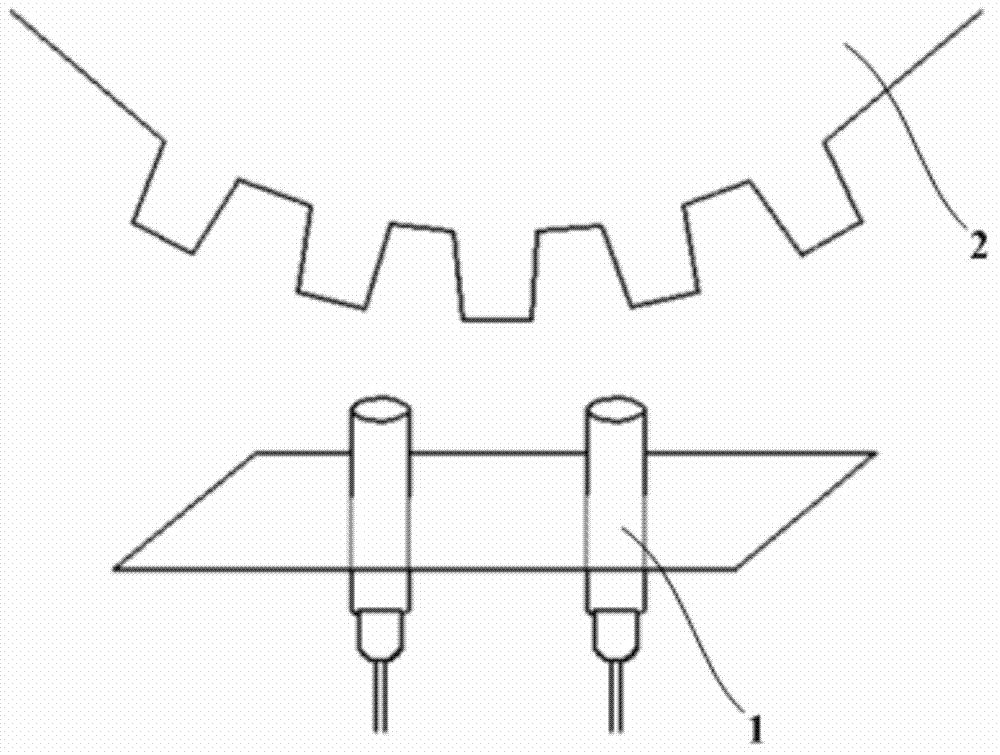

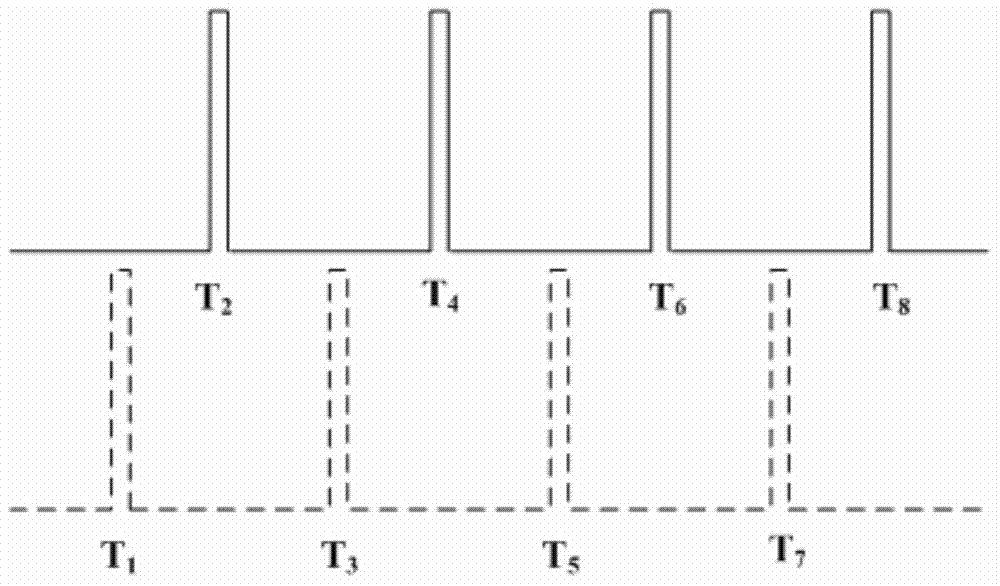

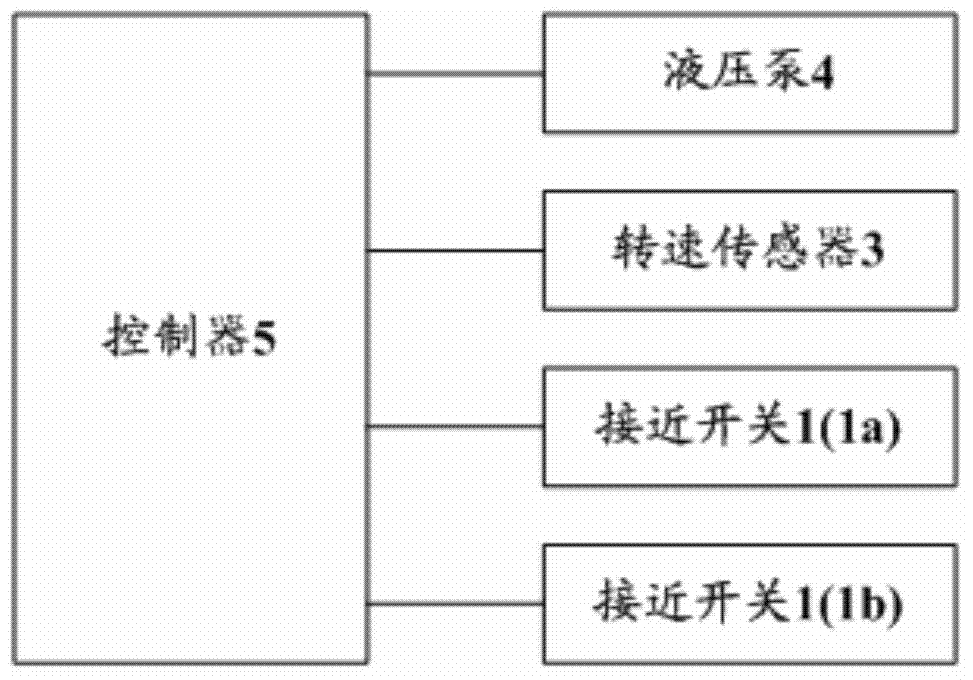

[0031] In order to improve the accuracy of rotation angle measurement, embodiments of the present invention provide a rotation angle measurement method, device, system and construction machinery. In the technical solution of the present invention, the controller obtains the rotational speed of the induction gear according to the rotational speed of the hydraulic pump and the control current of the hydraulic pump, and obtains the variation of the rotation angle according to the rotational speed of the induction gear and the time difference between the sampling time and the generation time of the current induction pulse. The rough measurement value of the rotation angle and the change amount of the rotation angle obtain the fine measurement value of the rotation angle. Compared with the coarse measured value in the prior art, the fine measured value has greatly improved detection accuracy, which is beneficial to more precise control of the rotary motion of the rotary mechanism. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com