Method and device for modal test of automobile instrument panel skeleton

A technology of automobile instrument panels and test methods, which is applied in the directions of measuring devices, vibration tests, and machine/structural component tests, etc., which can solve the problems of wasting test time, time-consuming and laborious, and affecting test efficiency, etc., and achieves wide application range and accuracy high precision and accurate connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

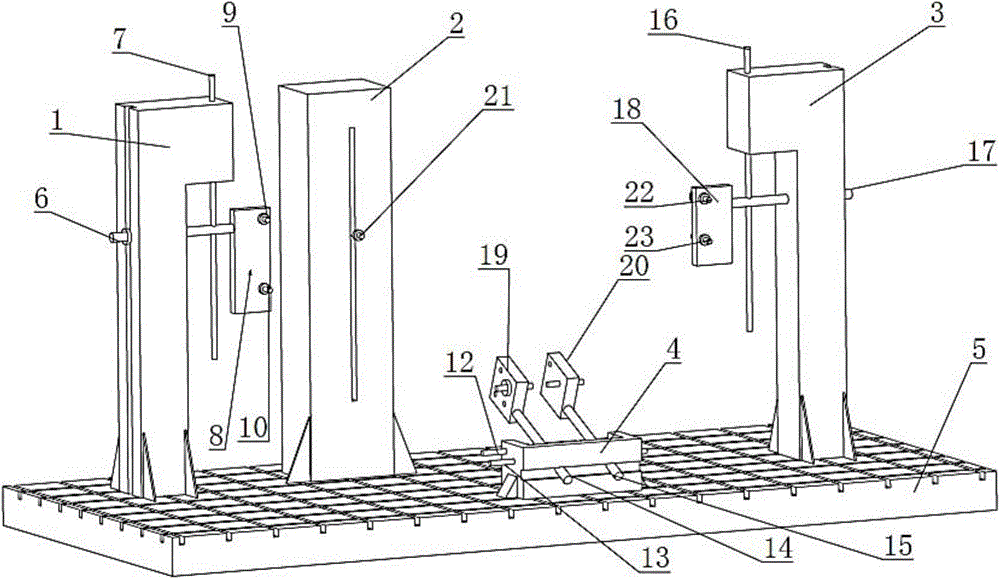

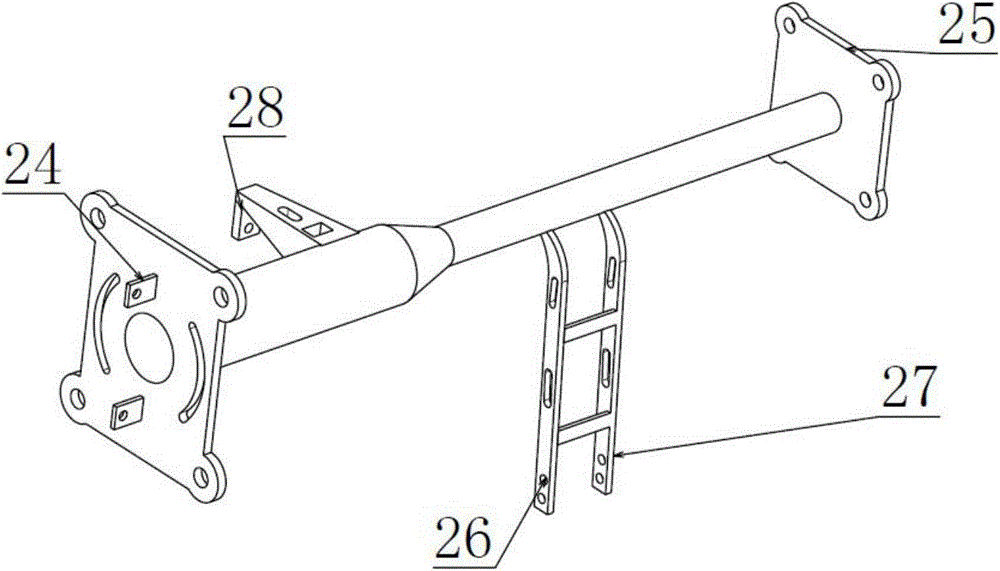

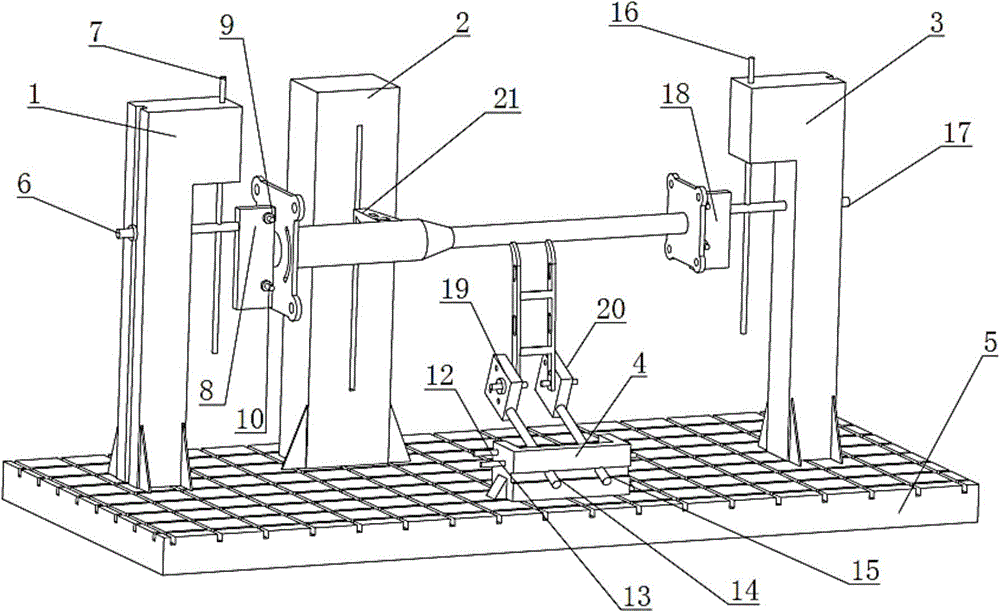

[0028] A method for modal testing of an automobile instrument panel skeleton, wherein the automobile instrument panel skeleton is fixed on a detection device, and the automobile instrument panel skeleton includes an instrument panel skeleton beam, a driver's side bracket 26, a passenger side bracket 27, an instrument panel The frame left side bracket 24, the instrument panel frame right side bracket 25 and the instrument panel frame rear side bracket 28 adopt the method of single-point excitation and multi-point vibration pickup, set the excitation point on the instrument panel frame beam, and Set vibration pickup points next to the points, and set vibration pickup points on the driver's side bracket, co-driver's side bracket and the rear side bracket of the instrument panel frame, and perform vibration excitation and vibration pickup in the x, y, and z directions respectively, and determine the analysis bandwidth of 256Hz Below; use PolyMAX to perform modal extraction on the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com