Non-magnetic steel thin sheet sample grinding suction table

A flake, non-magnetic steel technology, applied in the direction of grinding workpiece supports, can solve the problems of low efficiency, low grinding precision, large elastic deformation, etc., to simplify work procedures, improve work efficiency, and improve dimensional machining accuracy. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

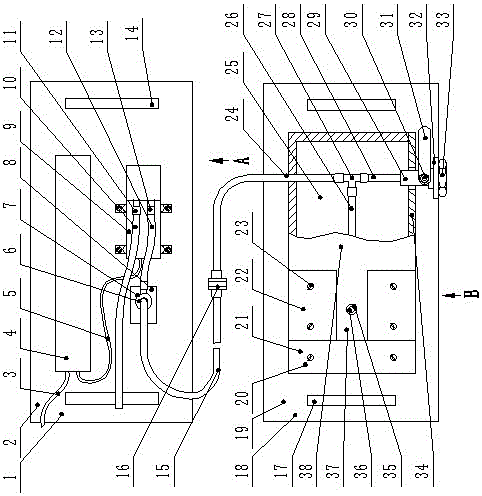

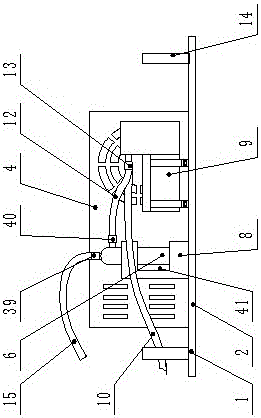

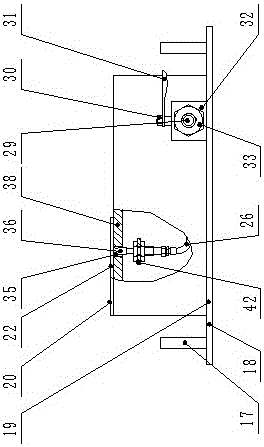

[0038] See this example figure 1 , figure 2 versus image 3 , It includes a suction table and auxiliary devices, characterized in that: the suction table is a suction table 18 including an iron bottom plate 19 and a vacuum suction cup 36, and the auxiliary device is a vacuum pump device 1; a suction table is installed on the suction table 18 The box 20, the suction table box 20 is fixed on the iron bottom plate 19, an outer mounting plate 32 and two handles 14 at both ends are also installed on the iron bottom plate 19, and the leak-proof ball valve 29 is fastened on the outer mounting plate 32. The top plate 38 is used as the work surface of the grinding parts. On the left side of the top plate 38, the horizontal clamping plate 21 and the two vertical clamping plates 22 are fastened by countersunk screws. At both ends of the clamping plate 21, a clamping groove 37 is formed between the two longitudinal clamping plates 22, and the width of the clamping groove 37 is greater than...

Embodiment 2

[0043] The difference between this embodiment and the first implementation of the suction table is that three vacuum suction cups 50 for impact plates are installed in the suction table box 20, and the top plate 38 of the suction table box 20 has three suction cup through holes 49, and each impact plate uses vacuum. The upper end of the suction cup 50 is inserted into the corresponding suction cup through hole 49 (one suction cup through hole 49 is inserted), and a four-way joint 47 is installed in the suction table box 20, and three of the joints are connected by a short suction cup connecting pipe. 48 is connected to the impact plate with a vacuum chuck 50, and the other joint is connected to a three-way joint 27. Each impact plate uses a vacuum chuck 50 to suck one impact workpiece, and the impact plate slot 51 places three impact workpieces, see Image 6 , Others are the same as the first embodiment of the suction table.

[0044] The size of a single workpiece is 55mm in leng...

Embodiment 2

[0050] In this embodiment, the second embodiment of the suction table is used to realize the present invention. The impact workpiece is placed in the clamping slot 51 of the impact plate, and the rest is the same as the first embodiment of the suction method.

[0051] Description

[0052] The top plate 38 of the above two embodiments is required to have sufficient hardness to offset the repeated wear of a large number of samples, so its material is selected as 45 steel.

[0053] The heat treatment process is determined as quenching heat treatment, and the plan is as follows:

[0054] ⑴Quenching treatment: enter the furnace at 860℃, heat for 1 hour, and then water quench.

[0055] ⑵ Tempering treatment: Tempering in an oven at 200°C for 2 hours.

[0056] ⑶ Hardness value: 52 HRC

[0057] Vacuum pump 9

[0058] In the grinding process, a large amount of grinding wheel chips, waste materials and cooling grinding fluid are produced, and some of them will inevitably enter the vacuum pipeline. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com