Working method of general test platform for power module based on embedded

A general-purpose test platform and power module technology, applied in power test and other directions, can solve the problems of different interface methods, many power screen modules, and inability to test a variety of power modules, achieving the effect of strong compatibility and stable standards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

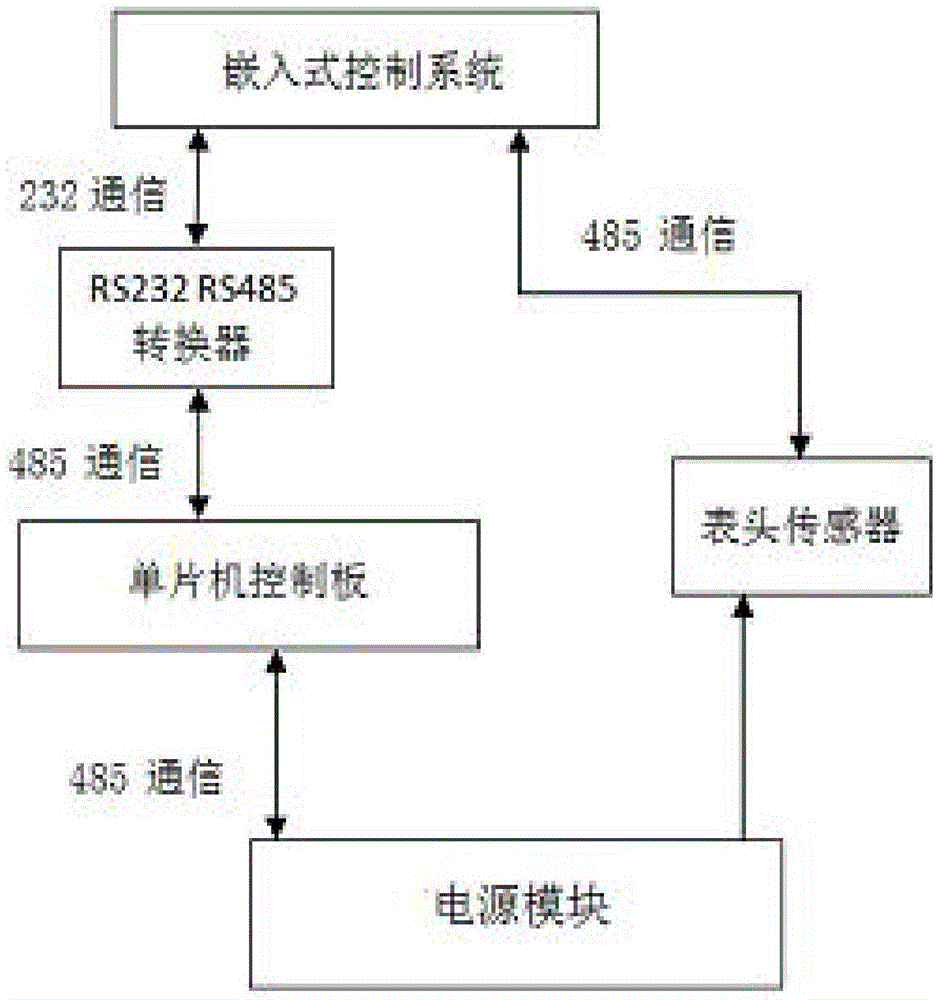

[0033] A working method based on an embedded general test platform for power modules, such as figure 1 As shown, the test platform includes an embedded control system, a single-chip microcomputer control board and a meter sensor, wherein the embedded control system exchanges data with the single-chip microcomputer control board through the RS-232 The embedded control system adopts the SUMSANGS5PV210 main chip, which can quickly process data and run the program. Its main function is to send control commands and recover the data returned by the meter sensor and the single-chip control board, and to store the power supply. The electrical signal data is convenient for detection; the single-chip control board contains two 8051 single-chip microcomputers, which control the closing and disconnection of relays and contactors through the high and low levels of the single-chip I / O pins, and short-circuit the test pins of the power module under test to control Different power modules; me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com