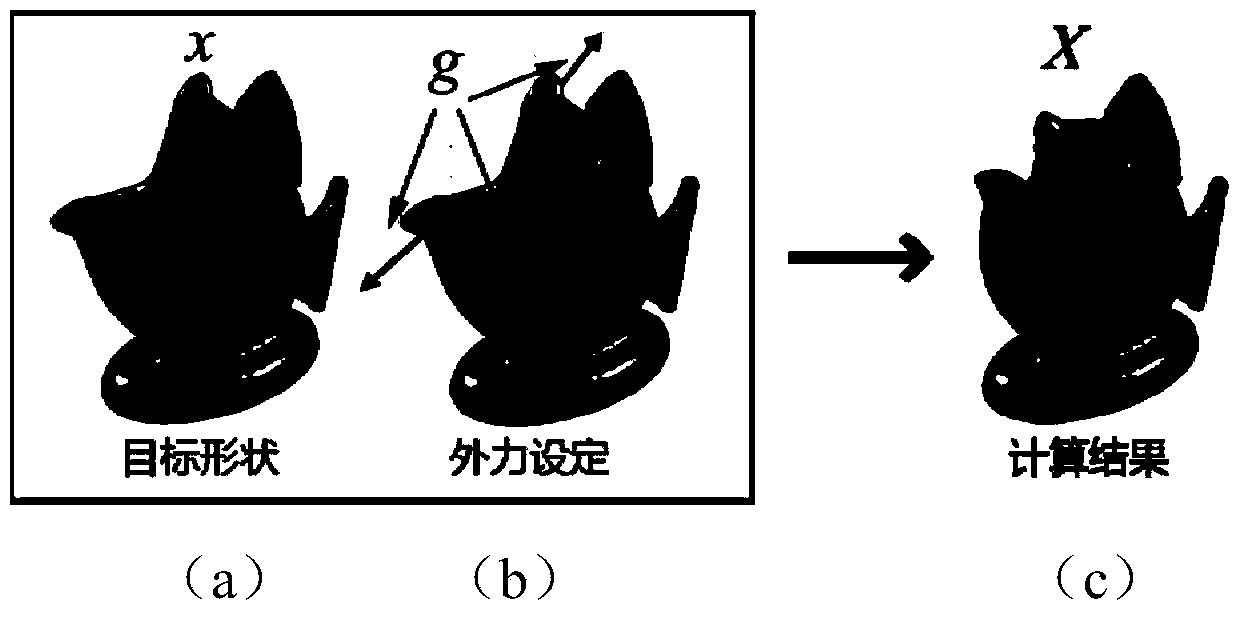

Reverse shape designing method for elastic object manufacturing

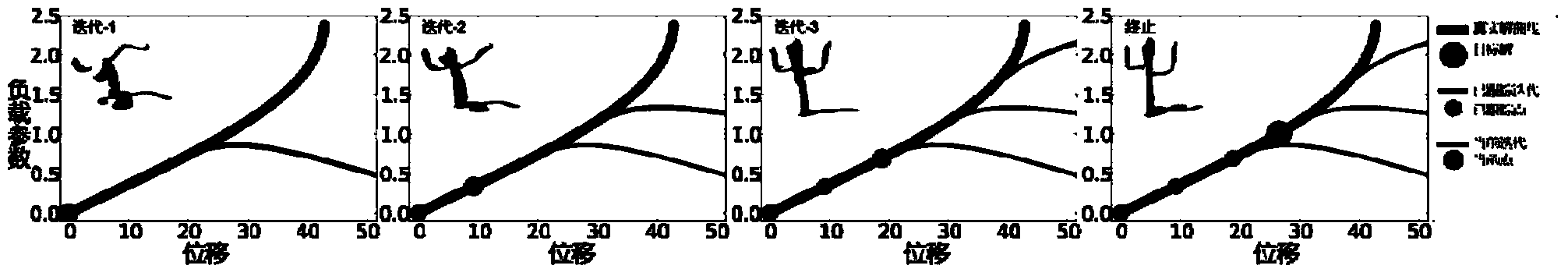

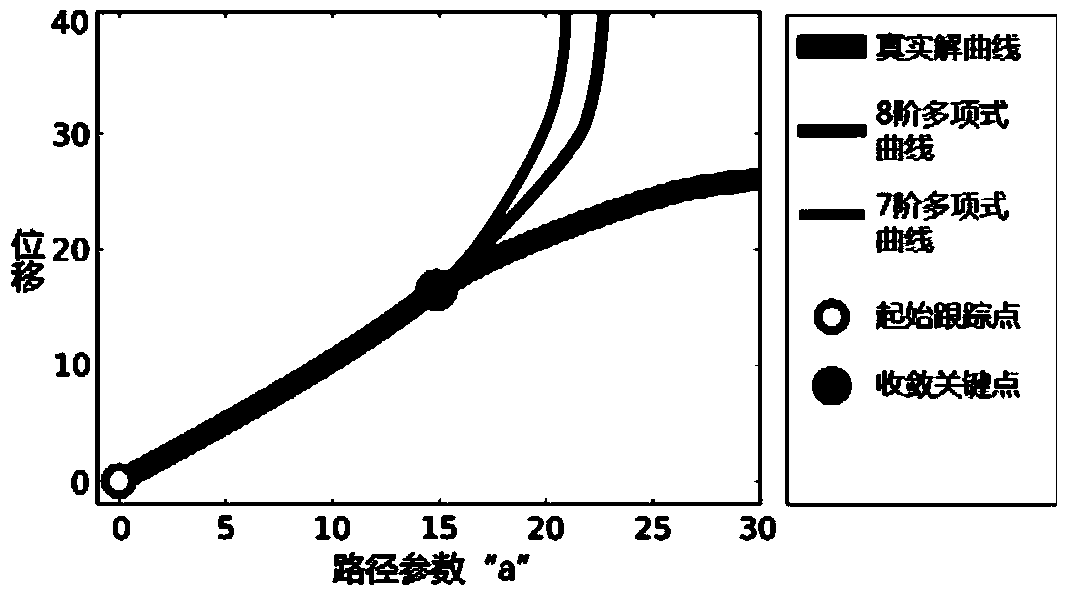

A design method and elastic object technology, applied in computing, special data processing applications, instruments, etc., can solve problems affecting the accuracy of results, difficulty in iteration step size, slow convergence, etc., to meet application requirements, smooth design experience, and solution speed Enhanced effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0158] The inventors designed and fabricated 7 different models (see Table 1 for statistical data) to evaluate and verify the inverse shape design method proposed in the present invention.

[0159] Table 1: Statistics of the experimental model

[0160] Model

number of vertices

number of tetrahedrons

Number of targets

Number of external forces

Stripes

4552

19552

1

1

14842

47077

1

1

mobile phone holder

18753

72355

1

3

Coat hanger

24323

98131

2

1 / 3

the eagle

19307

71235

1

1

Dinosaur

10673

32953

4

1 / 3 / 2 / 2

three branches

5093

24478

1

7

[0161] The manufacturing method of these elastic objects is as follows: firstly, a solid model is printed in 3D for making a silicone mold, and then cast with PU8400 elastic material to obtain the final elastic object. The following is the specific ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com