Dynamic aircraft assembly scene real-time and three-dimensional visualization method based on head-mounted displayer

A helmet-mounted display and aircraft assembly technology, applied to instruments, special data processing applications, electrical digital data processing, etc., can solve problems such as high hardware requirements, inability to realize dynamic modeling of assembly scenes, and complex operations, and achieve simple and convenient action modification , the effect of good user experience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

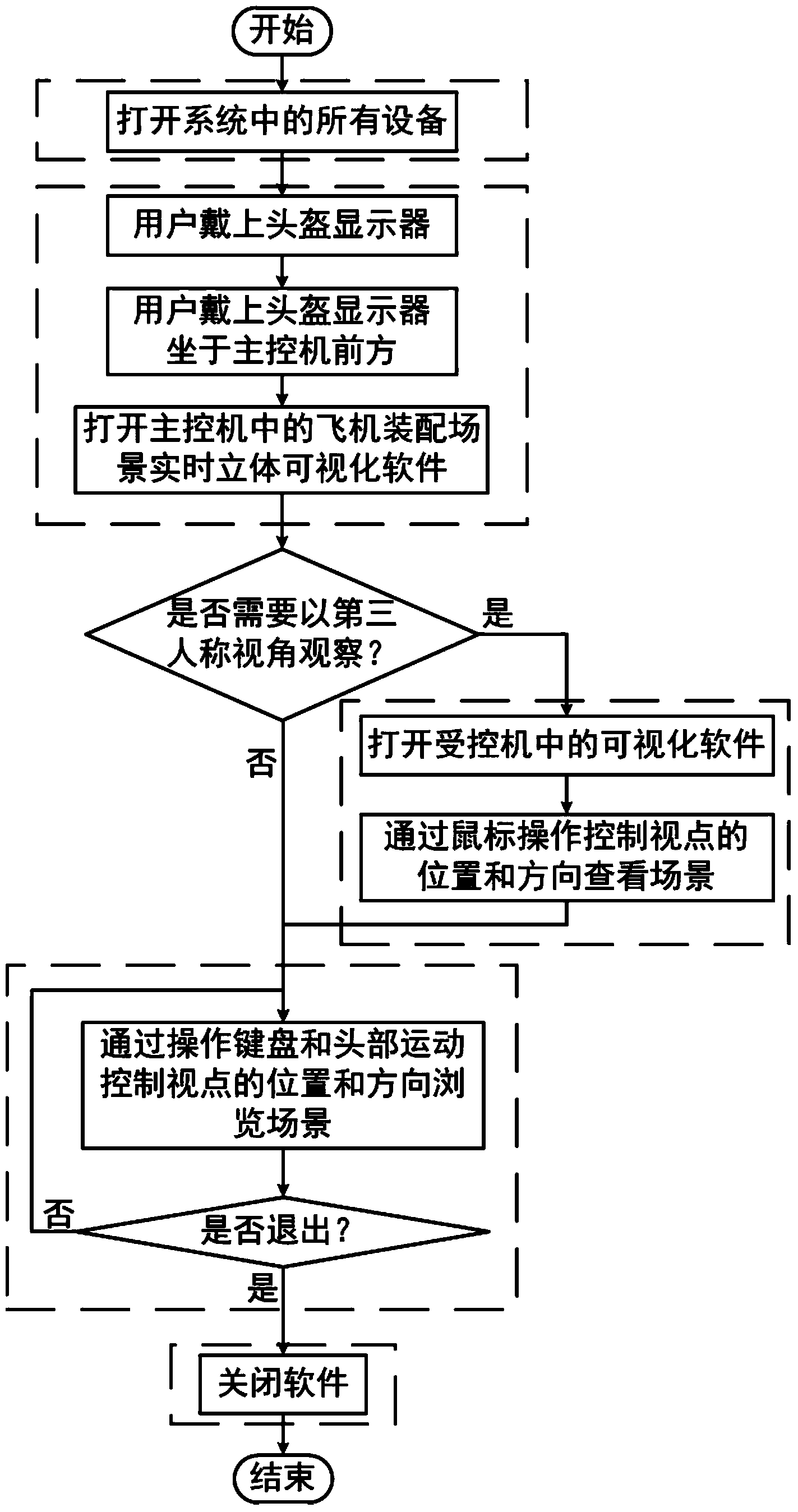

[0030] The present invention is based on the real-time three-dimensional visualization method of the dynamic aircraft assembly scene of the helmet display, such as figure 1 shown, including the following steps:

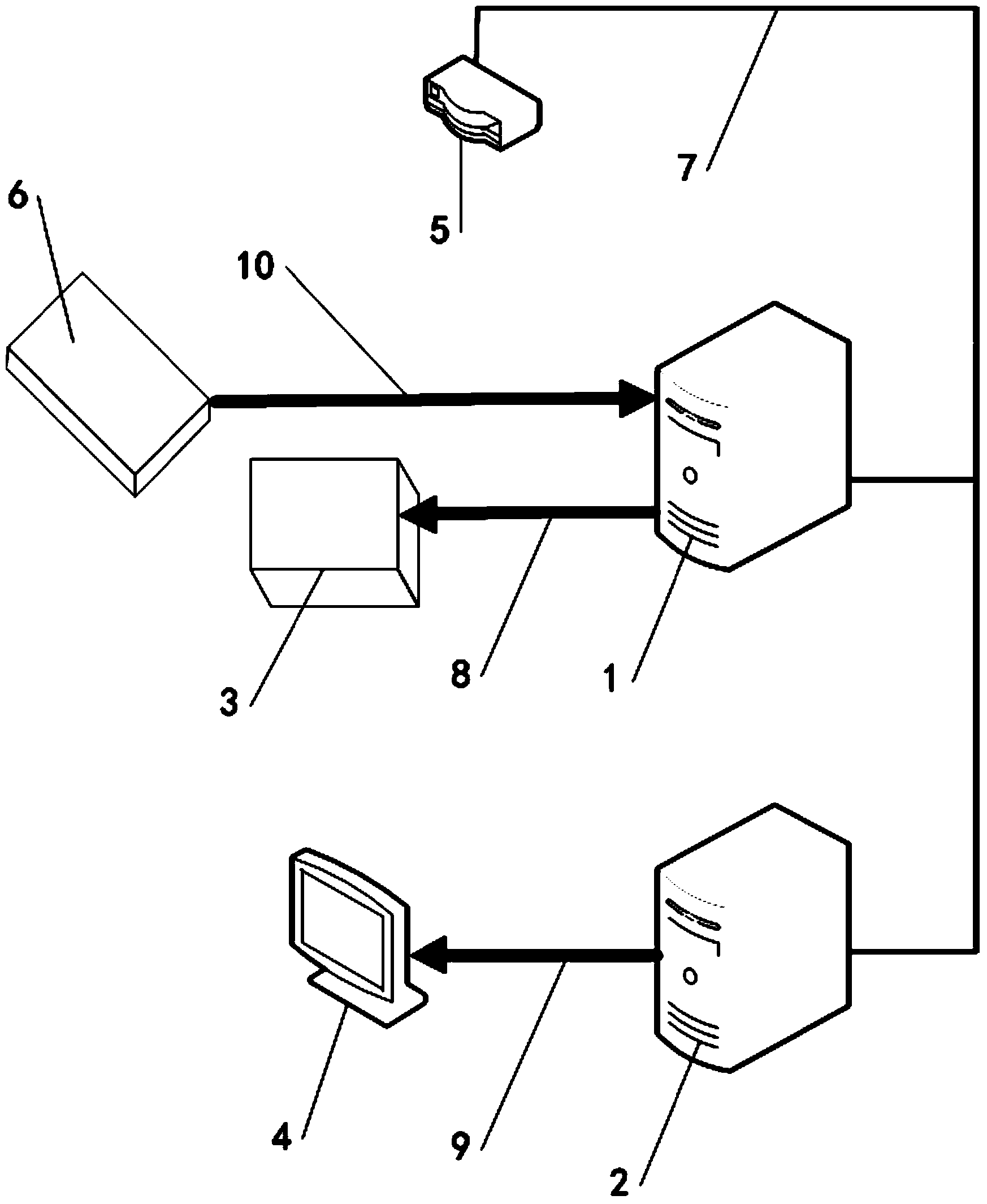

[0031] Step 1: Start all devices in the system. All hardware equipment used in the inventive method such as figure 2 As shown, it includes: computer (including the master computer 1 and the controlled computer 2 in the computer cluster network), the helmet display 3, the ordinary display 4, the wireless router 5, the position tracker 6, etc., the computer (including the master computer 1 and the controlled machine 2) are connected to the head-mounted display 3 and the ordinary display 4 through the connection lines 8 and 9 respectively, and the position tracker 6 is connected to the main control machine 1 through the connection line 10 . The wireless router 5 interconnects the master machine 1 and the controlled machine 2 through the LAN interface 7, so as to meet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com