Vacuum insulation material for blocking radiant heat

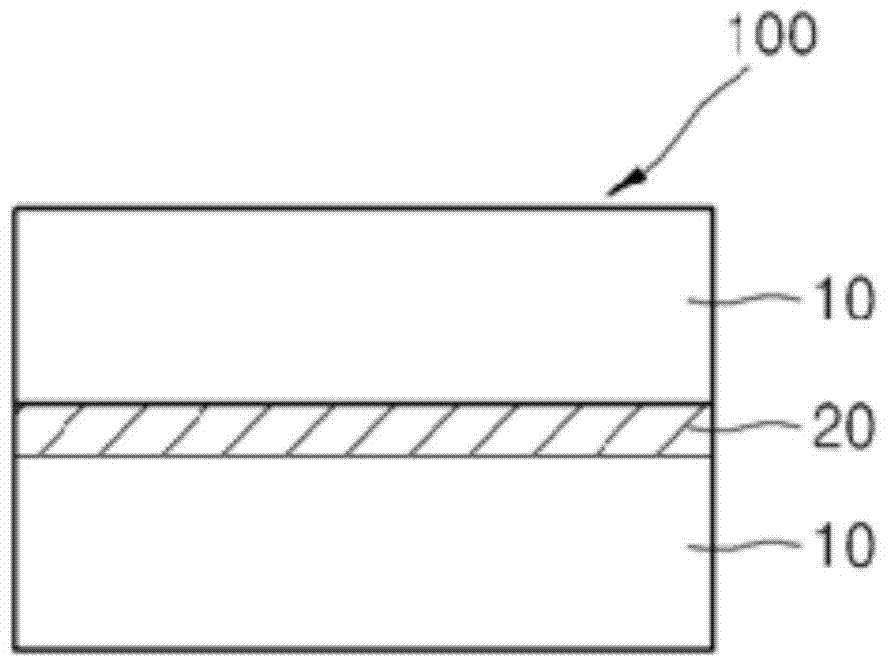

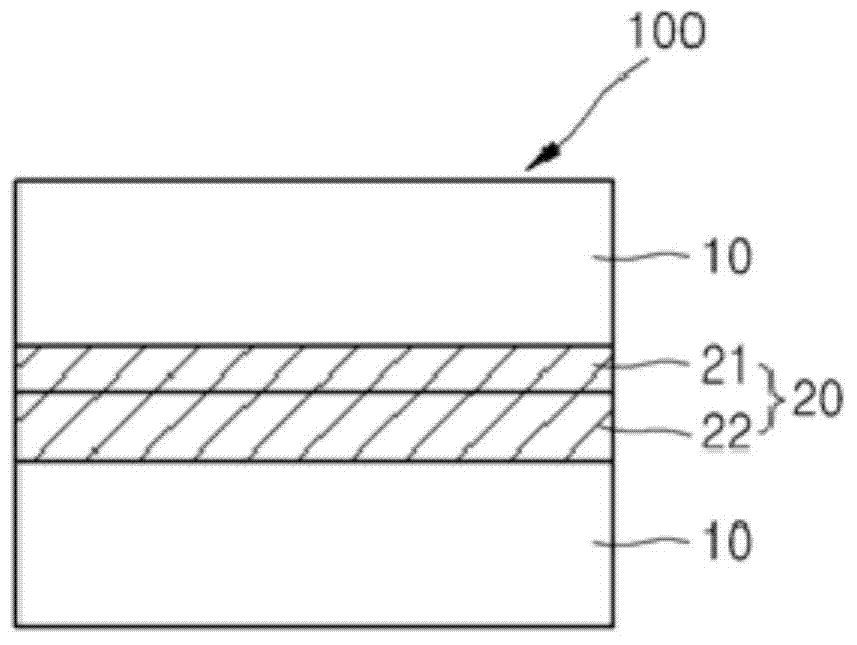

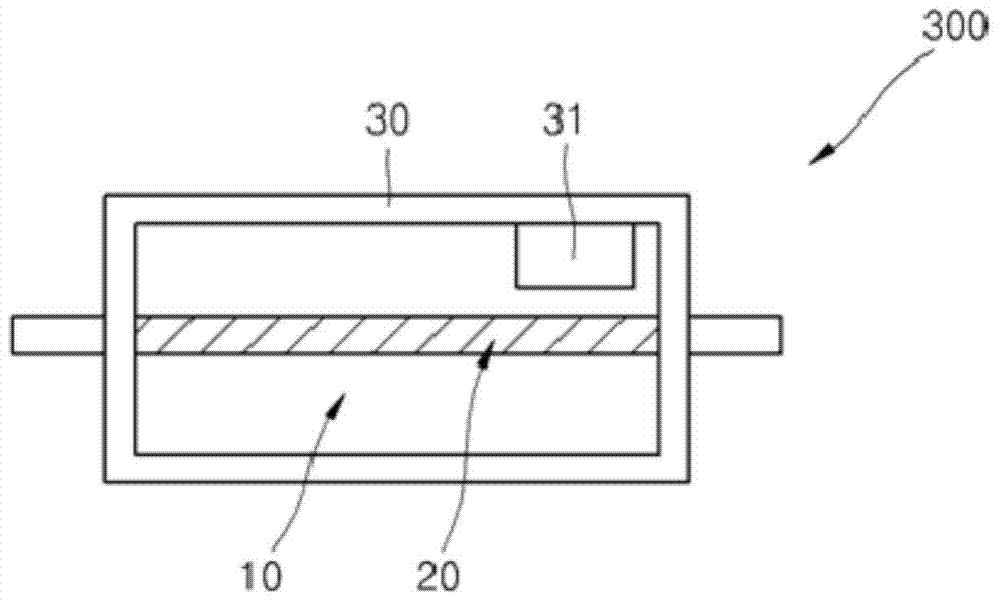

A technology of vacuum insulation materials and radiation heat resistance, which is applied in the direction of insulation improvement, thin material processing, heat exchange equipment, etc., can solve the problems of limited application of insulation materials, heat transfer can not be blocked, etc., to improve the initial insulation performance and long-term durability Excellent performance, the effect of blocking heat transfer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1 to Embodiment 8

[0045] The above-mentioned vacuum insulation materials were produced by inserting the films of Examples 1 to 8 shown in Table 1 below between the core layers constituting the core materials of the above-mentioned vacuum insulation materials, and the thermal conductivity at that time was measured. The emissivity of the metal comprising the above radiant heat blocking film was measured using an emissivity measuring device (INGLAS TIR100-2), and it may vary depending on the kind of metal and the state of the surface.

[0046] Table 1

[0047]

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com