Vacuum insulation material comprising a large specific surface area getter material

A technology of absorbing material and specific surface area, used in insulation improvement, thin material processing, heat exchange equipment, etc., can solve problems such as insulation performance decline, limitation, and reduction of initial thermal conductivity value.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0026] Preparation method of active substance for adsorption

[0027] The present invention can provide a kind of preparation method of active material for adsorption, it is characterized in that, comprises: step (a), one kind of being selected from calcium carbonate, barium carbonate, magnesium carbonate, aluminum carbonate or strontium carbonate is carried out acid treatment, Thereby the cation is selectively eluted; Step (b), extracting the above-mentioned eluted cation; One of them is sintered.

[0028] The present invention is characterized in that the calcium carbonate used is derived from limestone. The above limestone may contain silica, alumina, magnesia and the like as impurities. The above-mentioned limestone is a sedimentary rock mainly composed of calcium carbonate, which is white, gray or dark gray, black, and forms a block or layer. In the preparation of the active material for adsorption of the present invention, by using limestone as the main raw material...

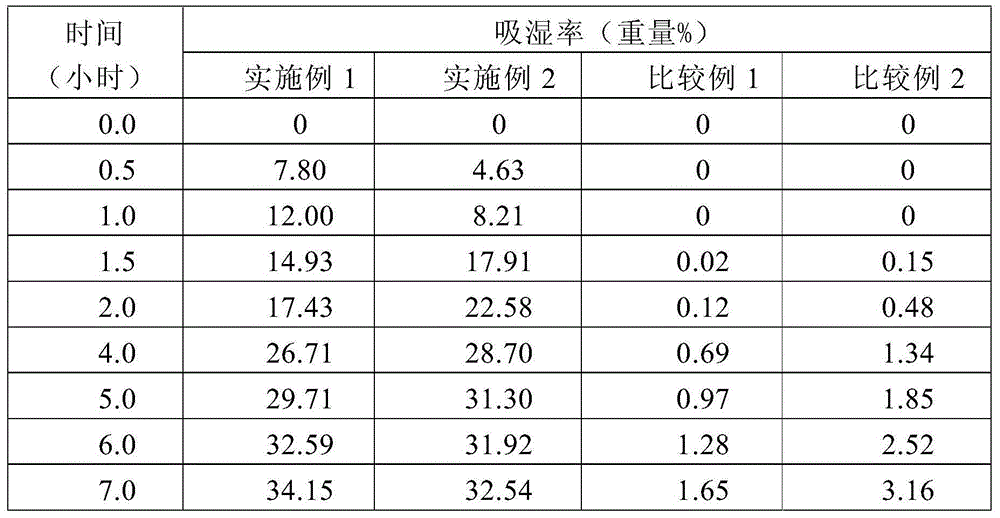

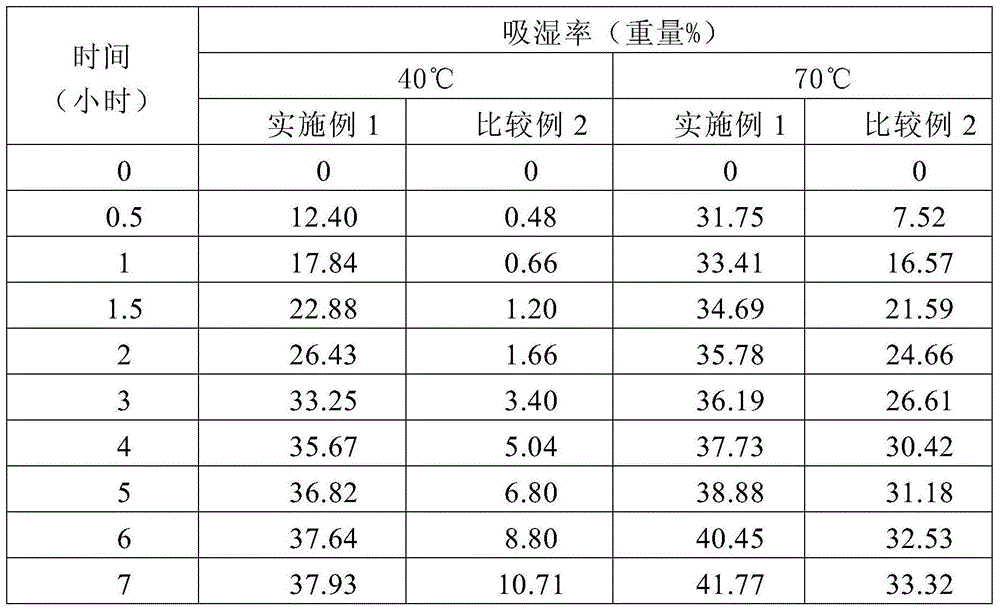

Embodiment 1

[0043] Mix 200 g of water in 30 g of citric acid to prepare a citric acid solution with a pH of 0. The citric acid solution prepared above was added to a solution obtained by sufficiently dispersing 30 g of calcium carbonate in a solid powder state into 300 g of water to selectively elute calcium ions. At this time, the extraction time was set to 30 minutes, and after filtering using filter paper, it dried in 130 degreeC oven for 1 hour. Sinter the dry material obtained by the above drying at a temperature of 900°C for 1 hour to prepare a product with a specific surface area of 15m 2 / g and a powder-shaped calcium oxide absorbent material with a diameter of 10 μm.

Embodiment 2

[0045] Mix 200 g of water in 30 g of citric acid to prepare a citric acid solution with a pH of 0. The citric acid solution prepared above was added to a solution obtained by sufficiently dispersing 30 g of barium carbonate in a solid powder state into 300 g of water to selectively elute barium ions. At this time, the extraction time was set to 10 minutes, and after filtering using filter paper, it dried in 130 degreeC oven for 1 hour. Sinter the dry product obtained by the above drying at 1000°C for 2 hours to prepare a product with a specific surface area of 40m 2 / g and a powder-shaped barium oxide absorbent material with a diameter of 15 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com