Fagopyrum tataricum tea production process

A production process, the technology of tartary buckwheat tea, applied in the field of production process of tartary buckwheat tea, can solve the problems of low standardized operation, small output, insufficient synthesis, etc., and achieve the effects of less loss of nutrients, increased output, and reduced cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

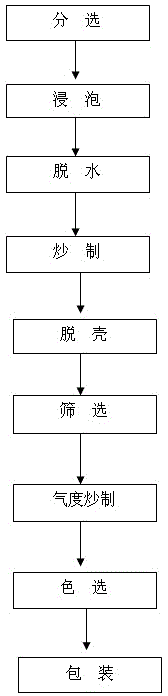

Image

Examples

Embodiment 1

[0024] A production process of tartary buckwheat tea, comprising the following steps: Step 1: screening of raw materials: putting tartary buckwheat raw materials into an electric winnowing machine, plugging in a power supply, the screening ratio is 95kg after screening 100kg of tartary buckwheat raw materials, and selecting Good tartary buckwheat is placed in the container;

[0025] Step 2: Cleaning, soaking, and dehydration: add water to the container, the ratio of water to buckwheat is 1:1, the water temperature is 10°C, and the soaking time is 24 hours; put the soaked buckwheat into a centrifuge for dehydration;

[0026] Step 3: Frying: Put the dehydrated tartary buckwheat into the temperature-adjustable frying equipment, put 40kg each time, at a temperature of 150°C, fry for 60 minutes, stir and fry evenly, so that the moisture in the tartary buckwheat Volatile;

[0027] Step 4: shelling and screening: put tartary buckwheat into the shelling machine to completely separate...

Embodiment 2

[0032] A production process of tartary buckwheat tea, comprising the following steps: Step 1: screening of raw materials: putting tartary buckwheat raw materials into an electric winnowing machine, plugging in a power supply, the screening ratio is 95kg after screening 100kg of tartary buckwheat raw materials, and selecting Good tartary buckwheat is placed in the container;

[0033] Step 2: Cleaning, soaking, and dehydration: add water to the container, the ratio of water to buckwheat is 1:1, the water temperature is 15°C, and the soaking time is 24 hours; put the soaked buckwheat into a centrifuge for dehydration;

[0034] Step 3: Frying: Put the dehydrated tartary buckwheat into the temperature-adjustable frying equipment, put 40kg each time, at a temperature of 170°C, fry for 70 minutes, stir and fry evenly to make the moisture in the tartary buckwheat Volatile;

[0035] Step 4: shelling and screening: put tartary buckwheat into the shelling machine to completely separate ...

Embodiment 3

[0040] A production process of tartary buckwheat tea, comprising the following steps: Step 1: screening of raw materials: putting tartary buckwheat raw materials into an electric winnowing machine, plugging in a power supply, the screening ratio is 95kg after screening 100kg of tartary buckwheat raw materials, and selecting Good tartary buckwheat is placed in the container;

[0041] Step 2: Cleaning, soaking, and dehydration: add water to the container, the ratio of water to buckwheat is 1:1, the water temperature is 20°C, and the soaking time is 24 hours; put the soaked buckwheat into a centrifuge for dehydration;

[0042] Step 3: Frying: put the dehydrated tartary buckwheat into the temperature-adjustable frying equipment, put 40kg each time, at a temperature of 180°C, fry for 80 minutes, stir and fry evenly to make the moisture in the tartary buckwheat Volatile;

[0043] Step 4: shelling and screening: put tartary buckwheat into the shelling machine to completely separate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com