A processing method for integrally forming a steel plate box cover

A processing method and steel plate technology, applied in metal processing equipment, manufacturing tools, feeding devices, etc., can solve problems such as complex and cumbersome process flow, uneven box cover edges, sharp raised parts, etc., and achieve simplified process steps and smooth High degree of safety and good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

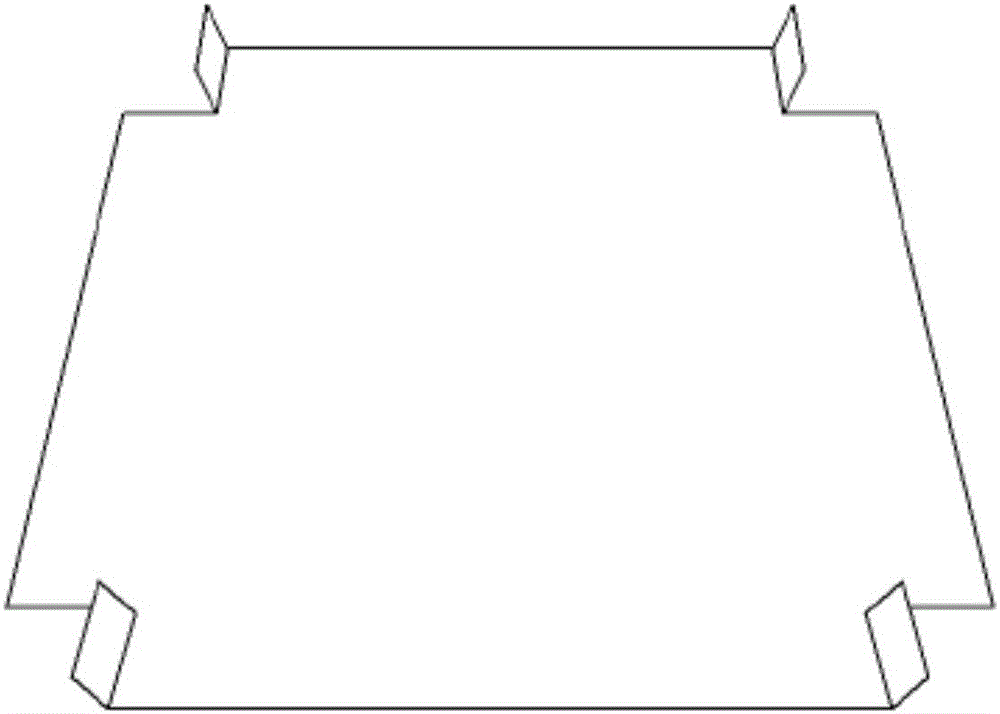

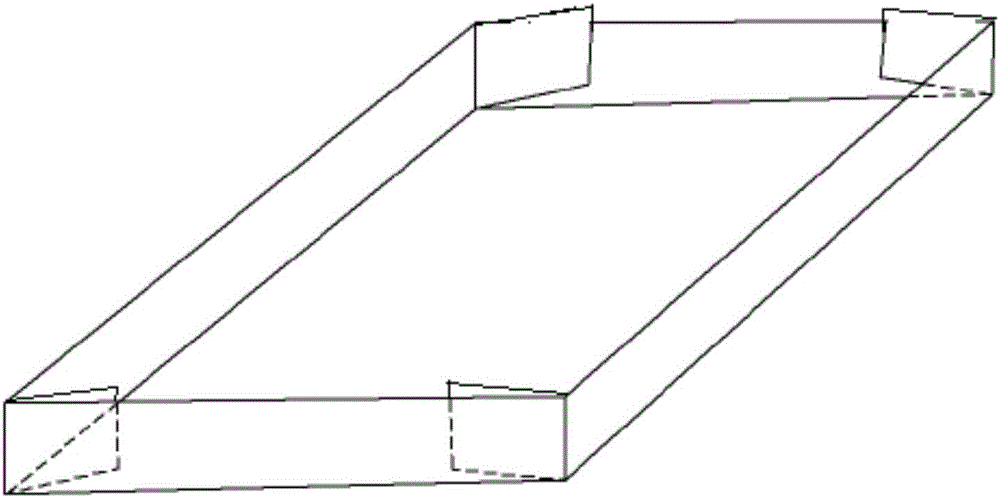

[0028] A processing method for integrated forming of a steel plate box cover, comprising the following steps: 1. Automatic feeding: use a vacuum suction cup-type automatic feeding device to carry out horizontal feeding of steel plates; The shearing and turning device punches the four corners of the steel plate, and the upper die of the corner punching and shearing and turning device punches off a pair of triangular sheets at each corner, and uses the lower die 1a of the corner punching and shearing and turning device Lift up, and simultaneously turn up the four corners of the steel plate; 3. Stamping and forming of the box cover: use the stamping forming device 2 to turn the four sides of the steel plate inwards to form a finished steel plate box cover.

[0029] Further, the horizontal slide rail is used to adjust the width of the steel plate c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com