Automatic fabric cleaning system

A technology of automatic cleaning and cloth cleaning mechanism, applied in mechanical cleaning, high-pressure cleaning, textile material processing, etc., can solve the problems of affecting environmental sanitation, increasing the burden on enterprises, not considering the collection and cleaning of slag, and improving environmental sanitation. , Improve the cleaning effect, save resources and manpower

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings.

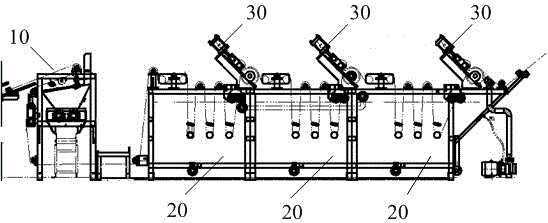

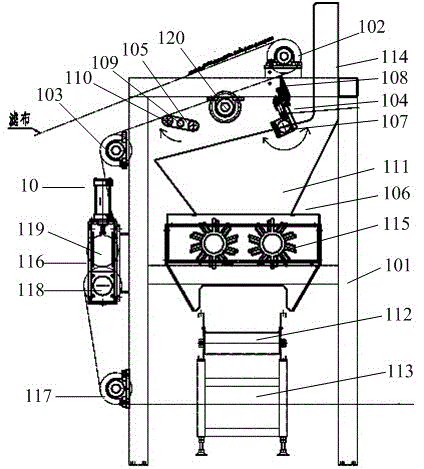

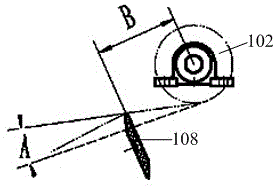

[0055] Such as figure 1 As shown, the first embodiment of the present invention provides an automatic cloth cleaning system, including a slag cloth separation mechanism 10, a cloth cleaning mechanism 20 and a cloth pricking liquid mechanism 30;

[0056] The slag cloth separation mechanism 10 is provided with a slag removal device, and the slag removal device separates the slag material from the cloth by moving relative to the surface of the cloth and causing the cloth to vibrate;

[0057] The cloth cleaning mechanism 20 includes a cleaning tank 201, and the cloth that has been deslag-removed through the slag-cloth separator passes through the cleaning tank 201 for cleaning;

[0058] The cloth liquid binding mechanism 30 is arranged on the cloth outlet side of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com