Connecting structure for preventing ground inside room of factory building from transmitting sedimentation to plinth and wall body

By using reinforced concrete floors and foam board partition structures in industrial plants, the problem of indoor ground settlement caused by soft soil foundations and the difference between column bases or walls is solved, achieving smooth ground and improving the working environment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

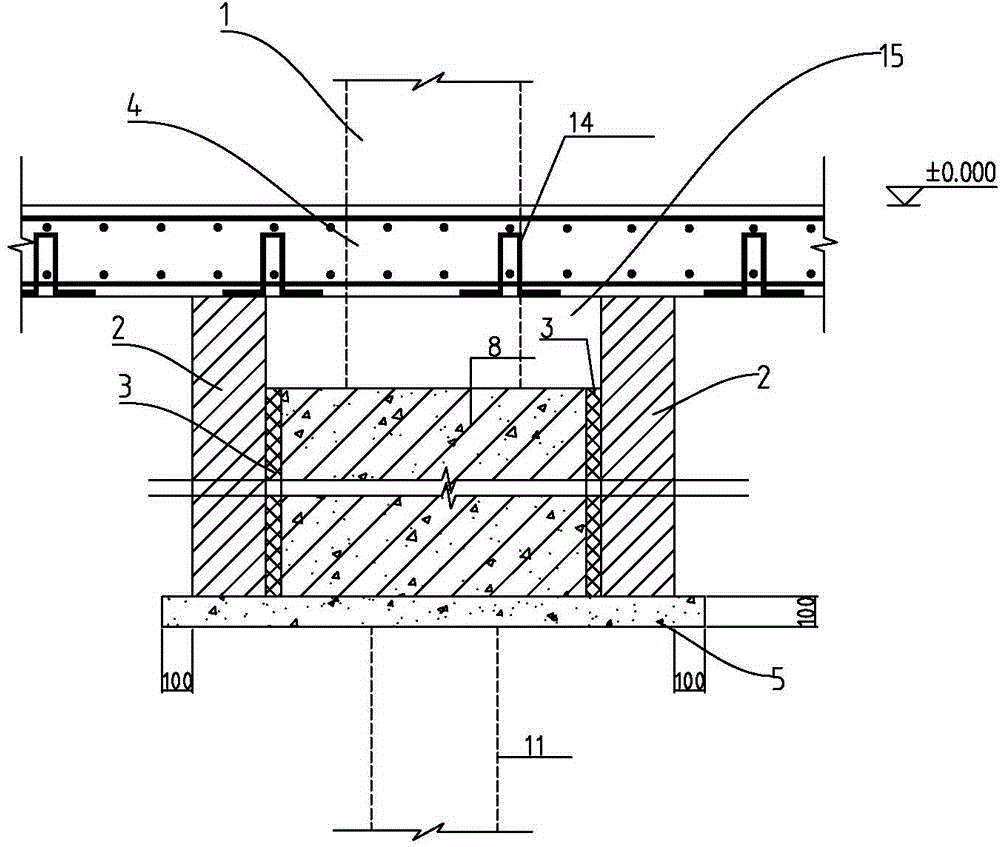

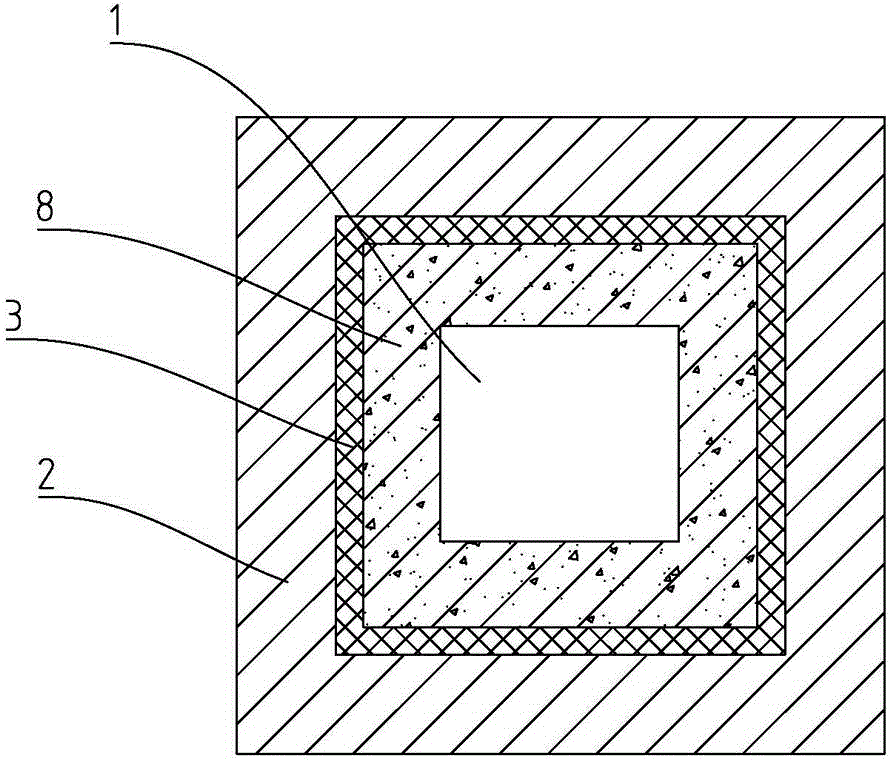

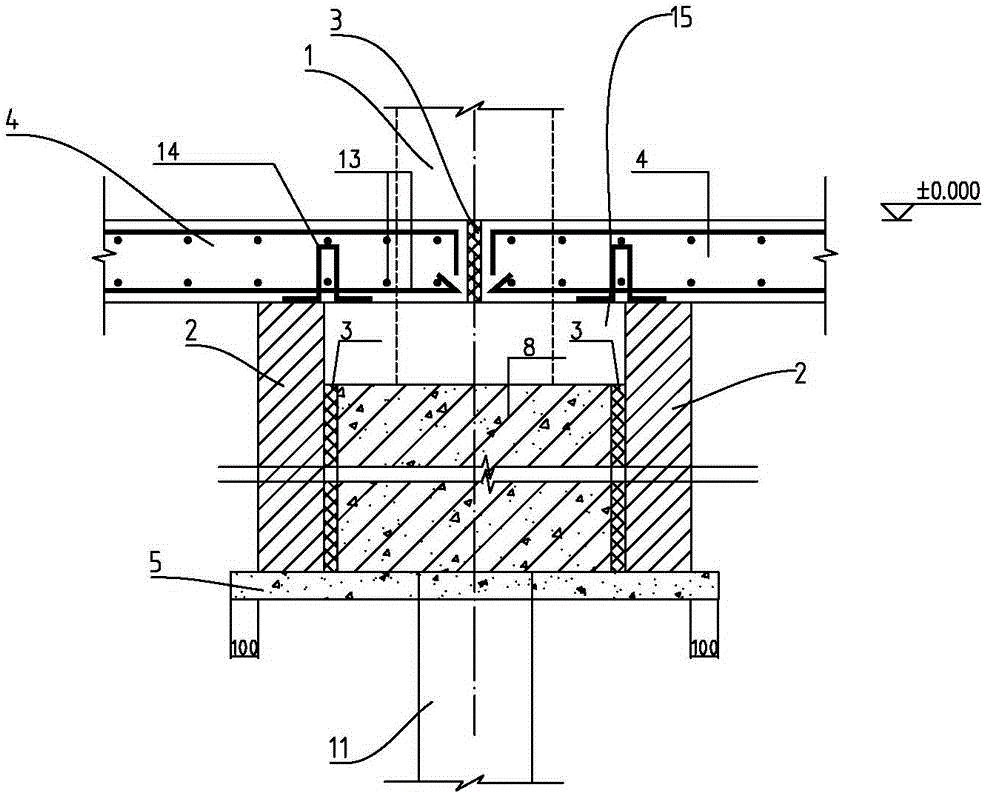

[0014] In this embodiment, the connection structure for separating the indoor ground of the factory building from the column base and the wall to transfer settlement includes a rectangular load-bearing column 1 connected sequentially from top to bottom, a rectangular concrete cap 8 and engineering piles 11, which serve as a factory building. The reinforced concrete floor 4 on the inner ground, the factory building wall 6 around the factory building and the factory building wall beam 7 at the lower part of the wall. The characteristics of this example are:

[0015] like figure 1 As shown in -3, brick walls 2 with a thickness of 240mm are built around the four sides of the concrete cap 8, and the brick wall and the concrete cap are separated by a 50mm thick foam board 3, so that displacement can occur between the brick wall and the concrete cap. The top of the brick wall 2 is connected to the reinforced concrete floor 4, and the bottom of the brick wall 2 is provided with a pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com