A method for leveling the primary wind speed of a pulverized coal boiler

A pulverized coal boiler and wind speed technology, which is applied in the field of primary wind speed leveling of pulverized coal boilers, can solve the problems of large test time and tedious primary wind leveling work, so as to save test time and power consumption, save adjustment and improve quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

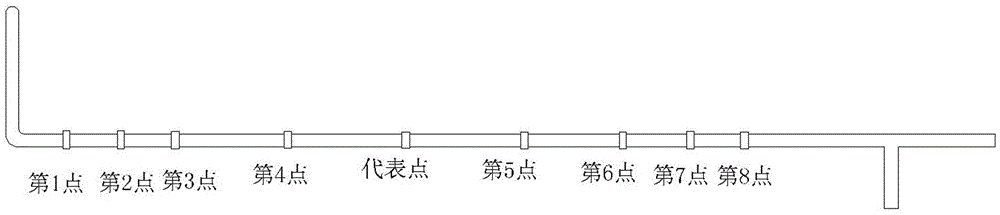

[0028] (1) The four primary air pipes on the same floor of the pulverized coal boiler are respectively recorded as #1 pipe, #2 pipe, #3 pipe and #4 pipe. Add a representative point, usually the middle point. as attached figure 1 .

[0029] (2) Before the test, the ventilation rate of the coal mill was estimated according to the wind speed of the primary air duct in the cold state to be adjusted, and the ventilation rate of the coal mill was adjusted to the calculated value.

[0030] (3) Use a prefabricated Pitot tube with a scale to measure the dynamic pressure at each point of the primary air duct, and measure the representative point dynamic pressure at the same time.

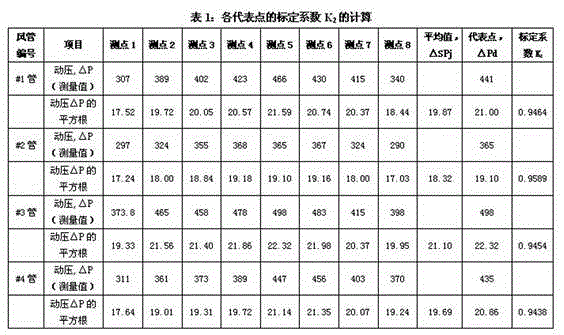

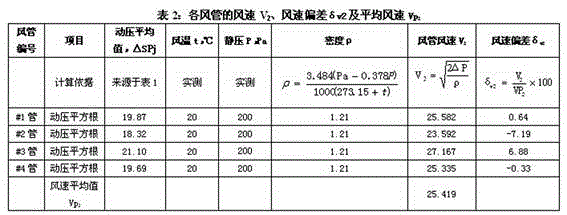

[0031] (4) Calculate the calibration coefficient K of each representative point of the primary air duct according to the measurement results 1 , each primary air duct wind speed V 1 , the wind speed deviation δv of each primary air duct 1 , you can refer to Table 1 and Table 2 for calculation.

[0032] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com