Anti-corrosion self-compensation low-temperature heat exchanger system for biomass circulating fluidized bed boiler

A low-temperature heat exchanger, circulating fluidized bed technology, applied in fluidized bed combustion equipment, lighting and heating equipment, fuel burning in a molten state, etc. ash and other problems, to avoid low-temperature corrosion, improve boiler efficiency, and improve thermal efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

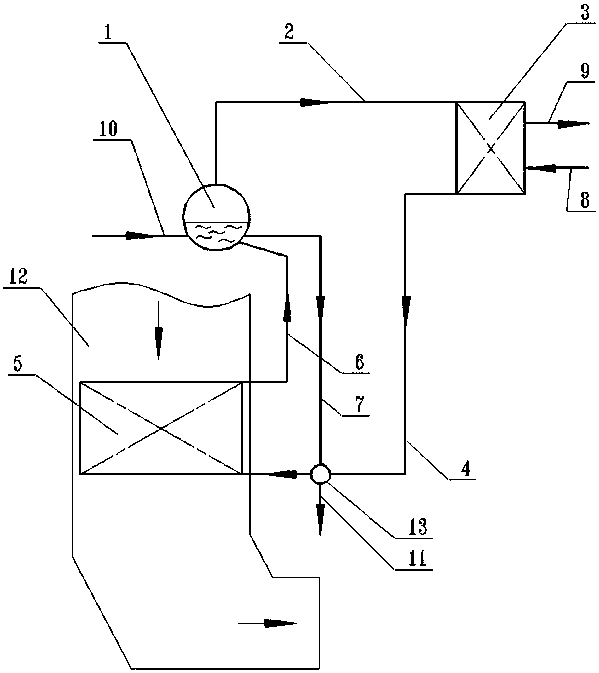

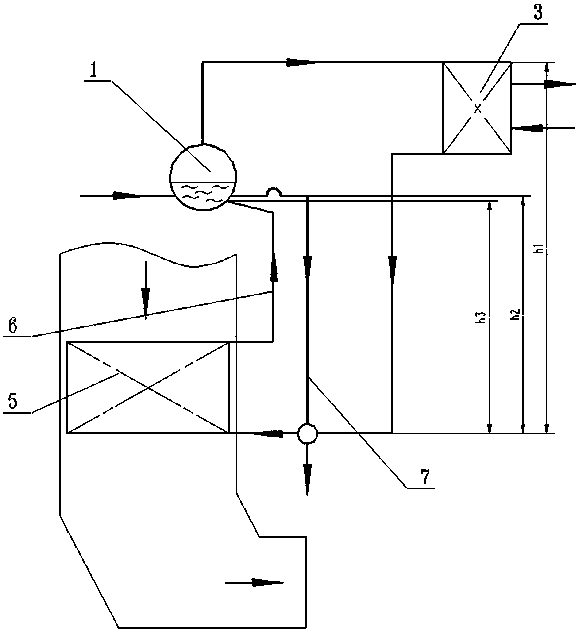

[0026] Example: as attached figure 1 As shown, an anti-corrosion low-temperature heat exchanger system for a biomass circulating fluidized bed boiler includes a low-temperature steam drum 1, an air heater 3 and a low-temperature heat exchanger 5. The low-temperature steam drum is located outside the tail flue of the boiler and installed on a steel On the rack, the air heater is arranged outside the boiler flue, and the low-temperature heat exchanger is arranged in the tail flue of the boiler as the last stage heating surface of the tail flue. The outlet of the low-temperature heat exchanger is connected to the low-temperature steam drum through the rising pipe 6. The inlet is connected to the collection box 13 through the piping system, the low-temperature steam drum and the collection box are connected through the downcomer 7, the inlet of the air heater is connected to the low-temperature steam drum through the saturated steam outlet pipe 2, and the outlet is connected to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com