Optical fiber laser sensor time division and wavelength division combined multiplexing method

A fiber laser and time division multiplexing technology, which is applied in the direction of using optical devices to transmit sensing components, the structure/shape of the active medium, etc., and can solve the problems of the maximum multiplexing number of only 16 array elements and a single wavelength division multiplexing technology.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

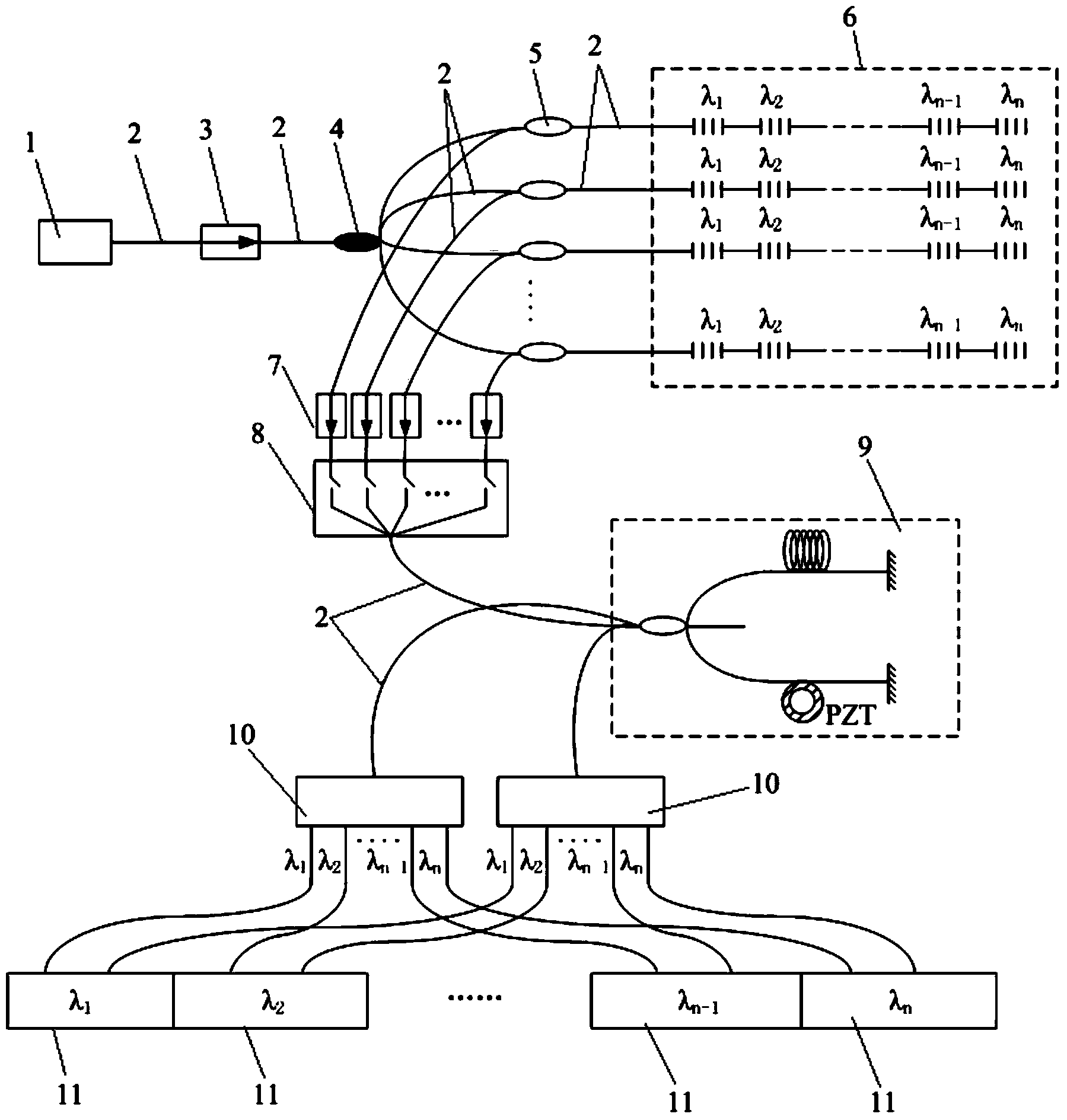

[0020] The time-division and wavelength-division joint multiplexing method of an optical fiber laser sensor comprises the following steps:

[0021] (1) Construct a time-division multiplexing structure: use an optical switch to modulate the intensity of the output light of the fiber laser in m channels to generate a narrow pulse optical signal with a high extinction ratio to achieve channel selection, use an m×1 type optical switch or use m independent optical switches, cooperate with m×1 beam combiner to realize channel selection of m channels, and then build a time division multiplexing structure;

[0022] (2) Time-division and wavelength-division joint multiplexing: use the wavelength-division multiplexing method to construct an n-element fiber laser sensor linear wavelength-division multiplexing array in each time-division multiplexing channe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com