Risk oriented hazard analysis method for chemical process device

A technology of risk analysis and process equipment, applied in the field of risk analysis, can solve the problems of low investment, large investment, and long time-consuming risk analysis, and achieve good technical effects, less time spent, and the effect of taking into account accuracy and engineering practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

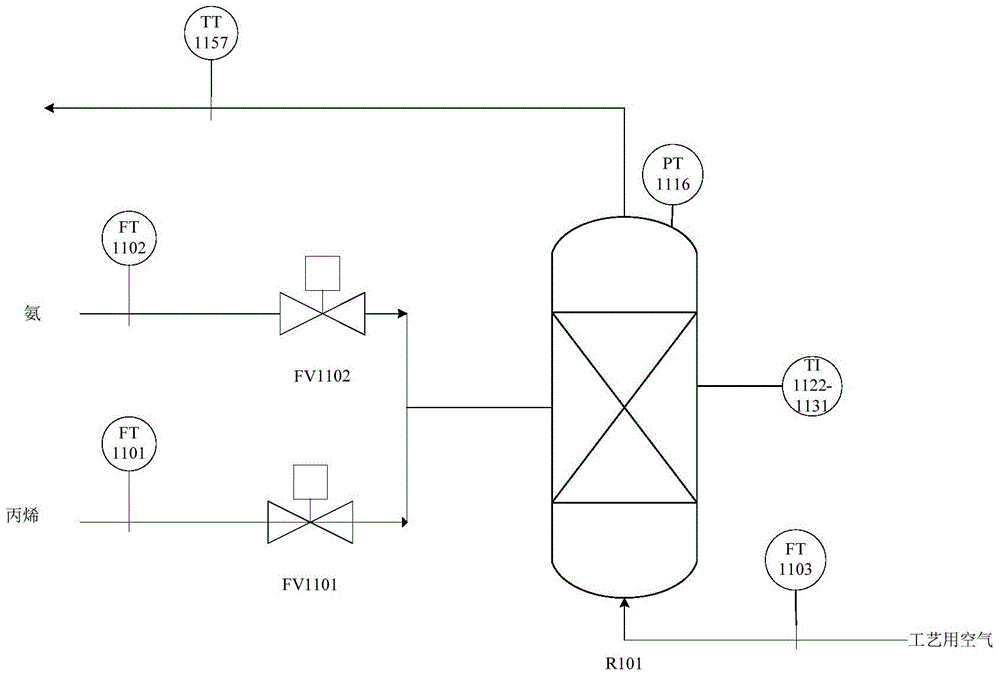

[0057] Acrylonitrile plant is a flammable, explosive, and highly toxic large-scale chemical plant. The production process has the characteristics of complex process, high technical requirements, and high risk. Once there is negligence in management and operation, accidents will occur , with the extension of the operating life of the device, the expansion of the production scale, the increase of the complexity of the process, and the existence of objective factors such as the aging of equipment and instruments, the safe production of the device becomes more important.

[0058] The acrylonitrile device synthesizes acrylonitrile (AN) by propylene and ammoxidation method, and the raw materials propylene, ammonia and air are reacted in a gas-solid phase fluidized bed reactor under the action of a catalyst. The catalyst bed height and density of the reactor are measured, and the pressure and differential pressure of the easily self-polymerized and blocked parts are measured by blowin...

Embodiment 2

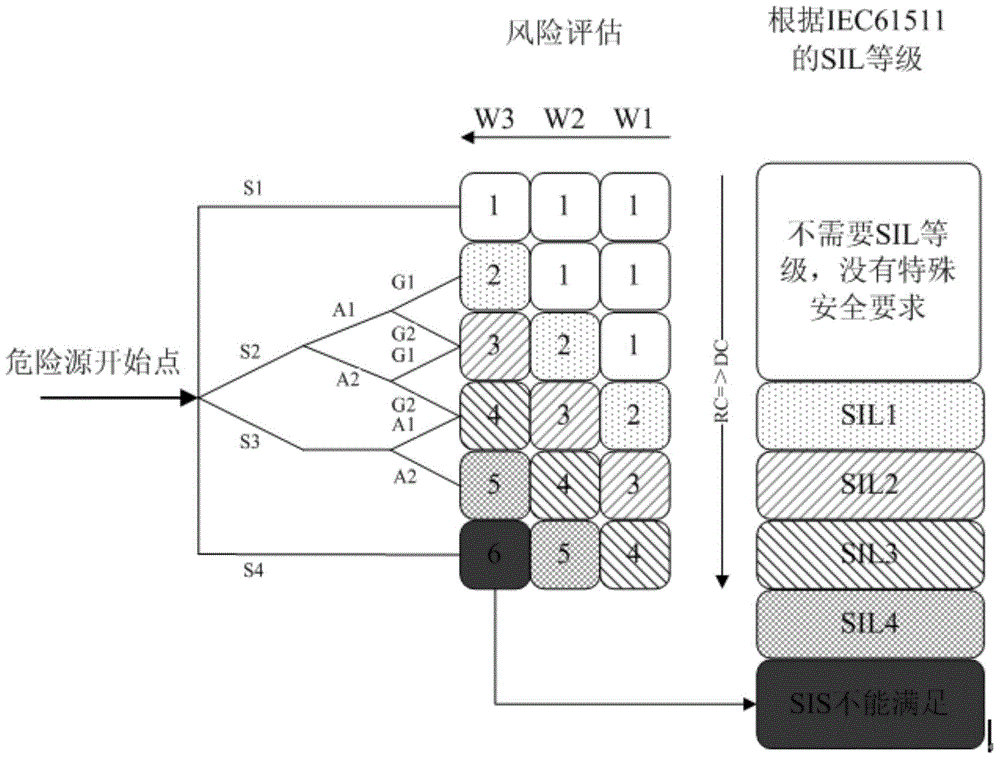

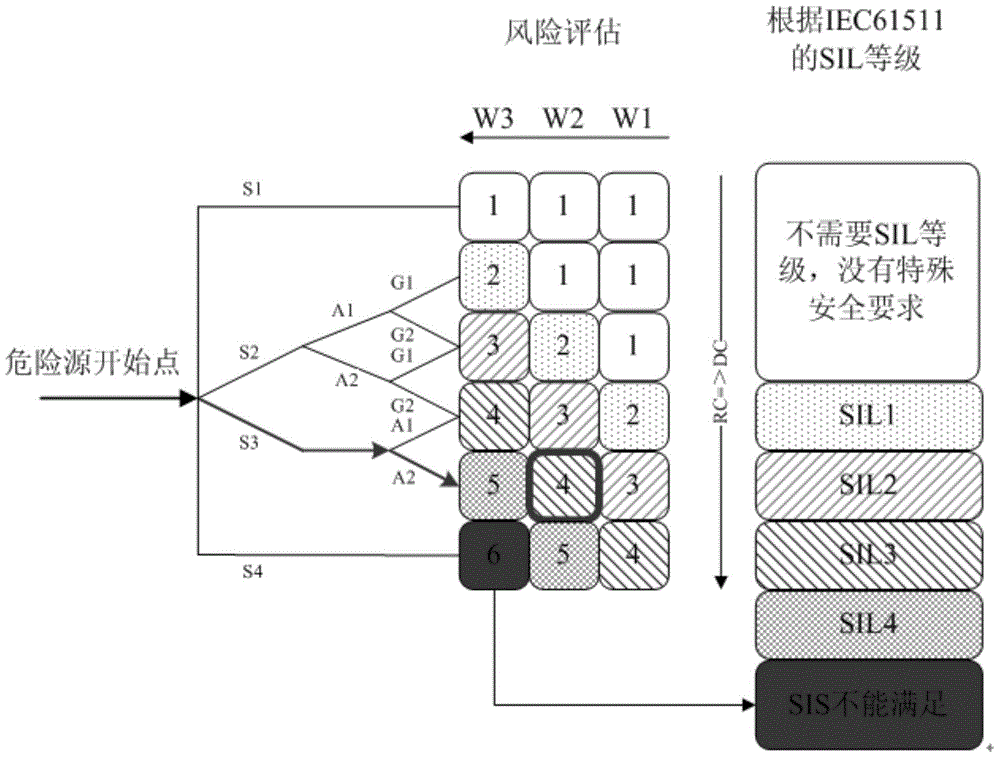

[0066] According to the conditions described in Example 1, the technical and management safety-related measures used in the chemical plant are identified and assigned a reliability level, which is used to prove that the safety-related measures are sufficient to prevent the occurrence of the identified safety accident. The selection of reliability levels for safety-related measures is based on comprehensive consideration of manufacturer data, regulatory safety requirements, plant operating experience, etc., and results are obtained in the context of the use of risk maps.

[0067] For example, according to the EU Pressure Equipment Directive (PED), components installed on pressure vessels containing hazardous substances are classified as category IV, and the set reliability level is DC6. Examples of assigning reliability classes to valves are given in Table 6.

[0068] In this way, the discrete distribution level corresponding to the reliability is defined, just as the discrete ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com