Phonon optical grating used for superconductivity dielectric resonant cavity phonon laser device

A phonon grating, superconducting medium technology, applied in phonon exciters, electrical components, circuits, etc., can solve the problem that the line width of the frequency is difficult to reach the ideal level, and achieve the effect of reliable and convenient production and production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

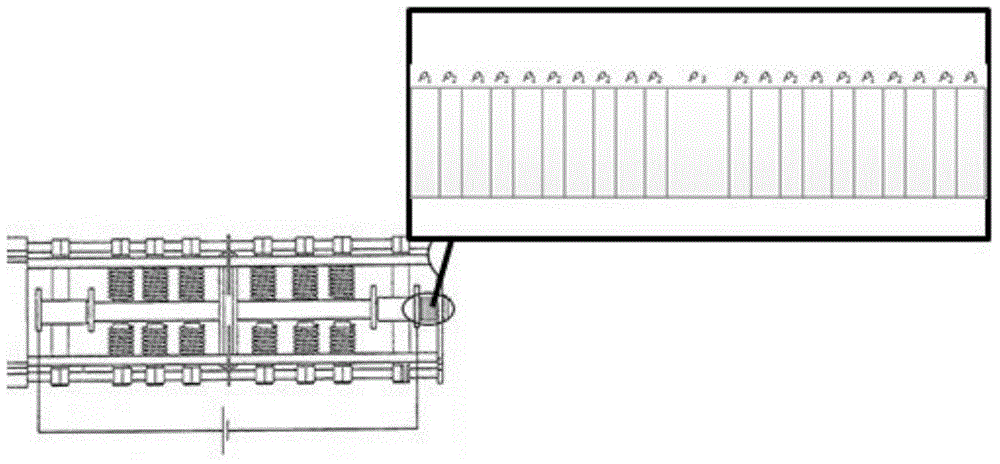

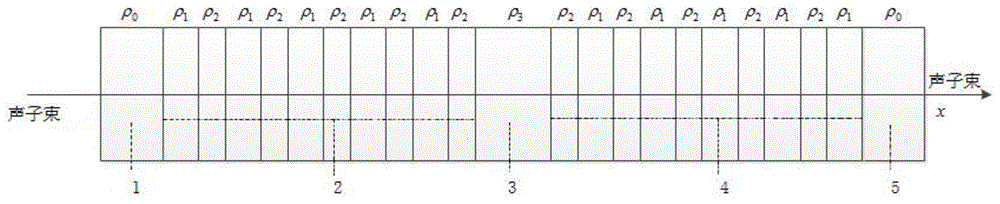

[0019] A phonon grating used in a superconducting dielectric resonator phonon laser provided by the invention is composed of a buffer layer, a medium layer and an impurity layer. Among them, the buffer layer is a phonon grating embedded in the output end of the superconducting dielectric resonator phonon laser. It is designed to fit the gap size of the phonon laser and prevent the wear of the dielectric layer. The dielectric layer is composed of two different materials alternately and repeatedly. The two parts of the dielectric An impurity layer is interposed between the layers, and the dielectric layer and the impurity layer are axially symmetrical as a whole.

[0020] The buffer layer of the phonon grating uses a ferrite material. The dielectric layer uses a phonon grating formed alternately by solids and fluids. The solids and fluids are respectively made of epoxy resin and water, and the thicknesses are 1 / 2 of the wavelength of sound waves in epoxy resin and water. times...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com