Motor wholly-moving type two-level electric cylinder

A technology of overall movement and electric cylinder, applied in the direction of electric components, electrical components, electromechanical devices, etc., can solve the problems of high manufacturing cost, long working stroke, increased working stroke, etc., achieve good servo control performance, long working stroke, reduce The effect of friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

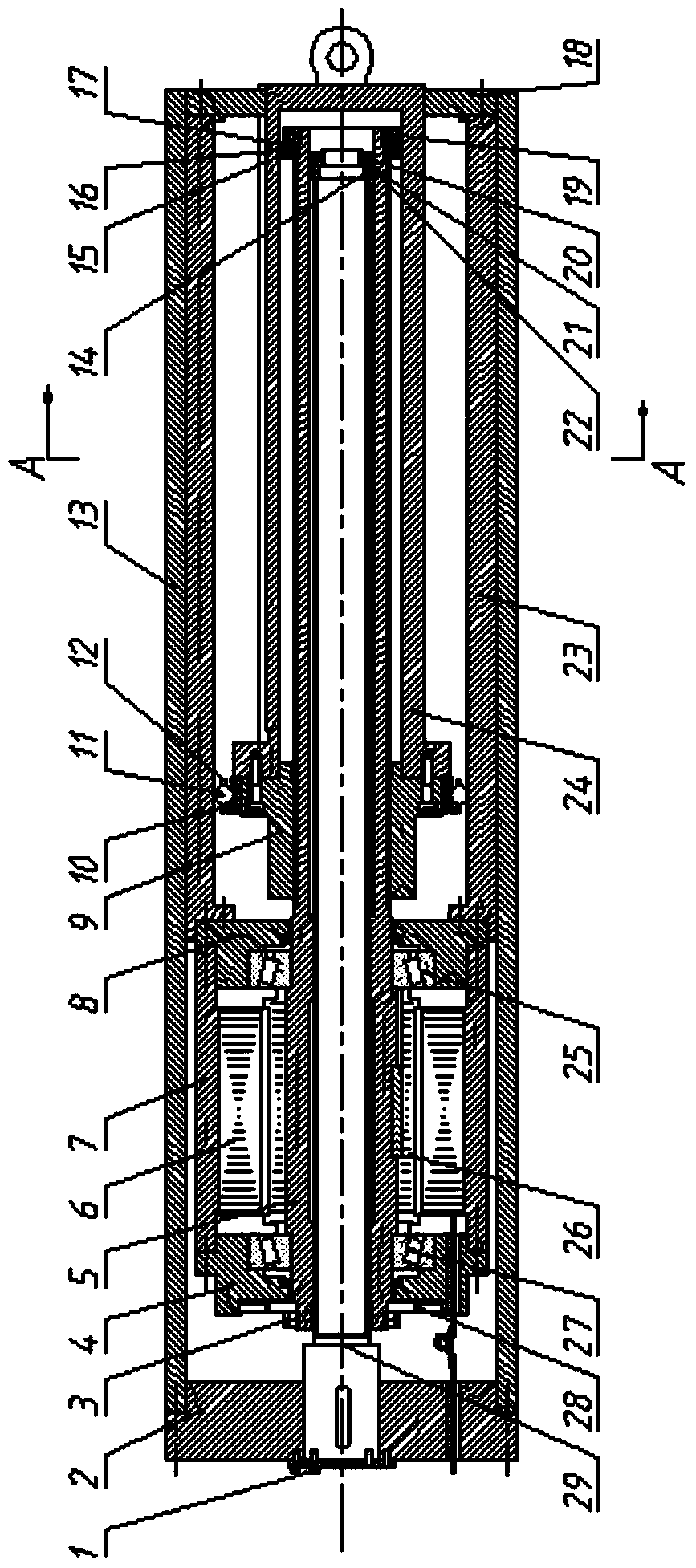

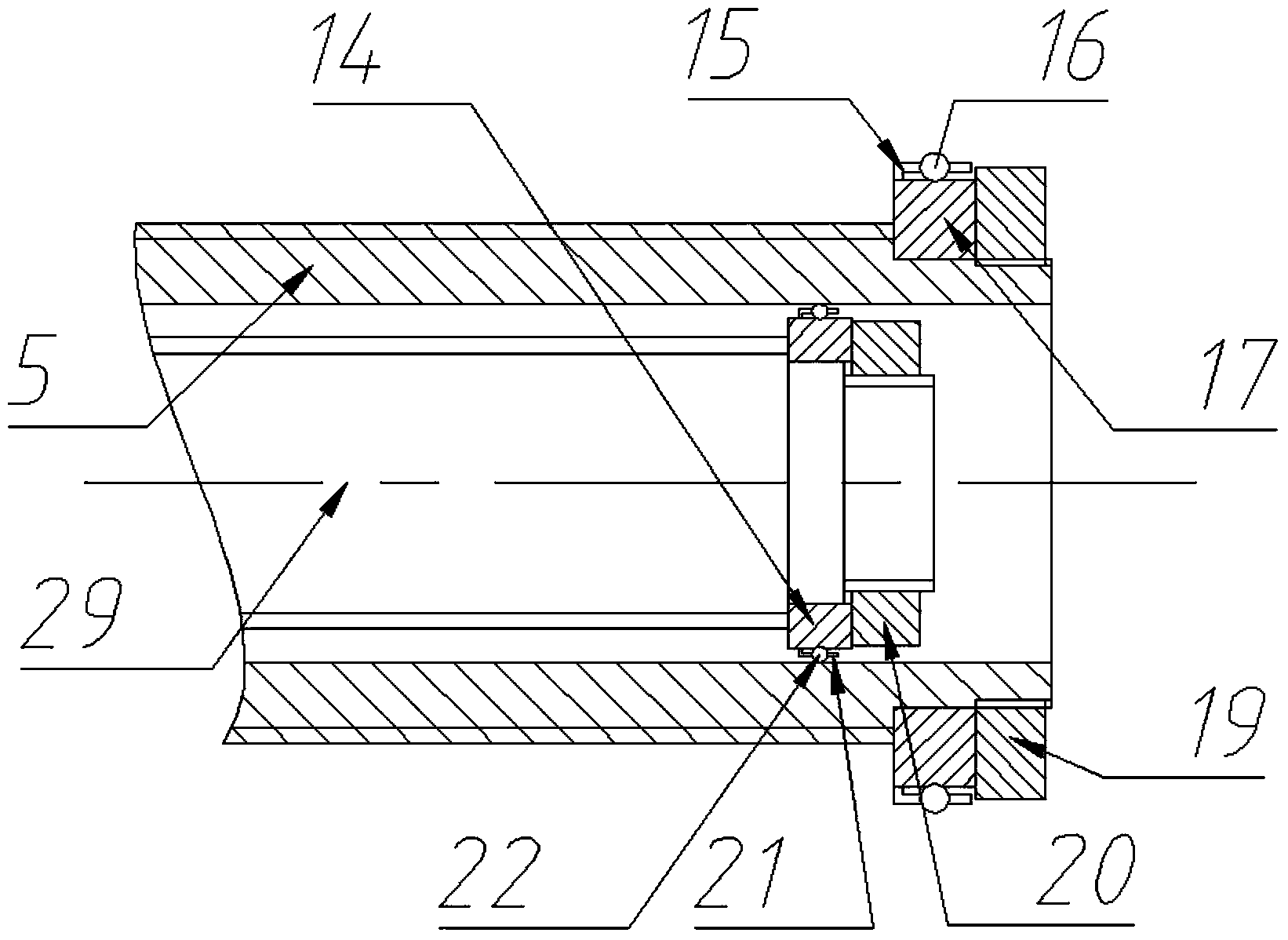

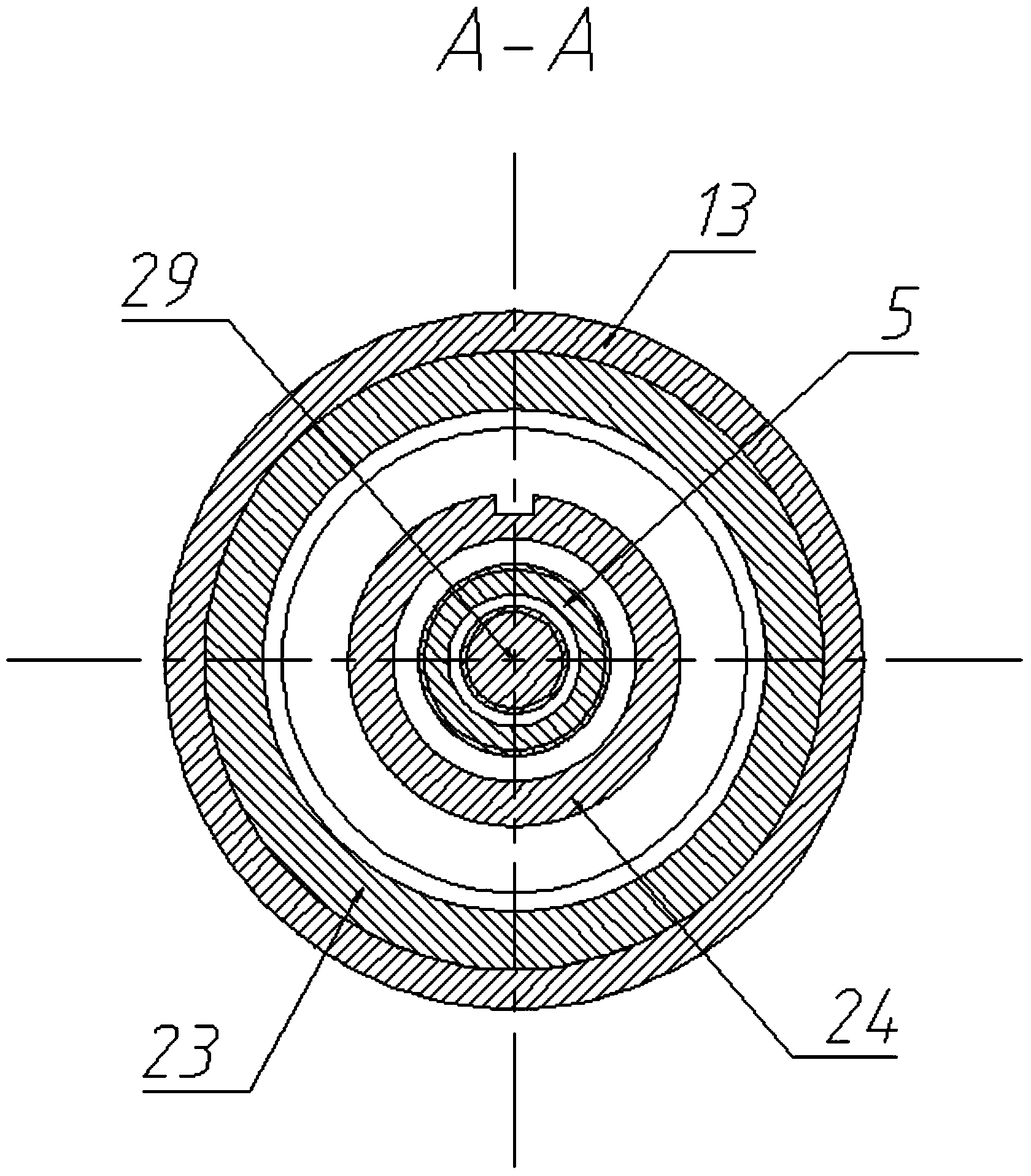

[0022] The present invention will be described in detail below in conjunction with the accompanying drawings.

[0023] Such as figure 1 , figure 2 , image 3 As shown, a two-stage electric cylinder with integral movement of the motor includes the cylinder bottom 2, the outer cylinder 13 is installed on the cylinder bottom 2, the first screw rod 29 is fixed in the middle of the cylinder bottom 2, and the cover plate 1 connects the cylinder bottom 2 and the second cylinder bottom. A screw rod 29 is connected together, and the first rotating drum 5 is installed on the first screw rod 29. The rear section of the first rotating drum 5 has an internal thread inside, and is threadedly matched with the first screw rod 29. The front section of the first rotating drum 5 There are external threads on the outside, and are threadedly matched with the first nut 9. The motor rear end cover 4 and the motor front end cover 8 are installed on the first drum 5 through the first thrust bearing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com