Tool and method for welding copper pipe and stainless steel pipe

A stainless steel tube and welding tooling technology, applied in welding/welding/cutting items, welding media, welding equipment, etc., can solve the problems of high welding cost, low efficiency, poor welding environment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

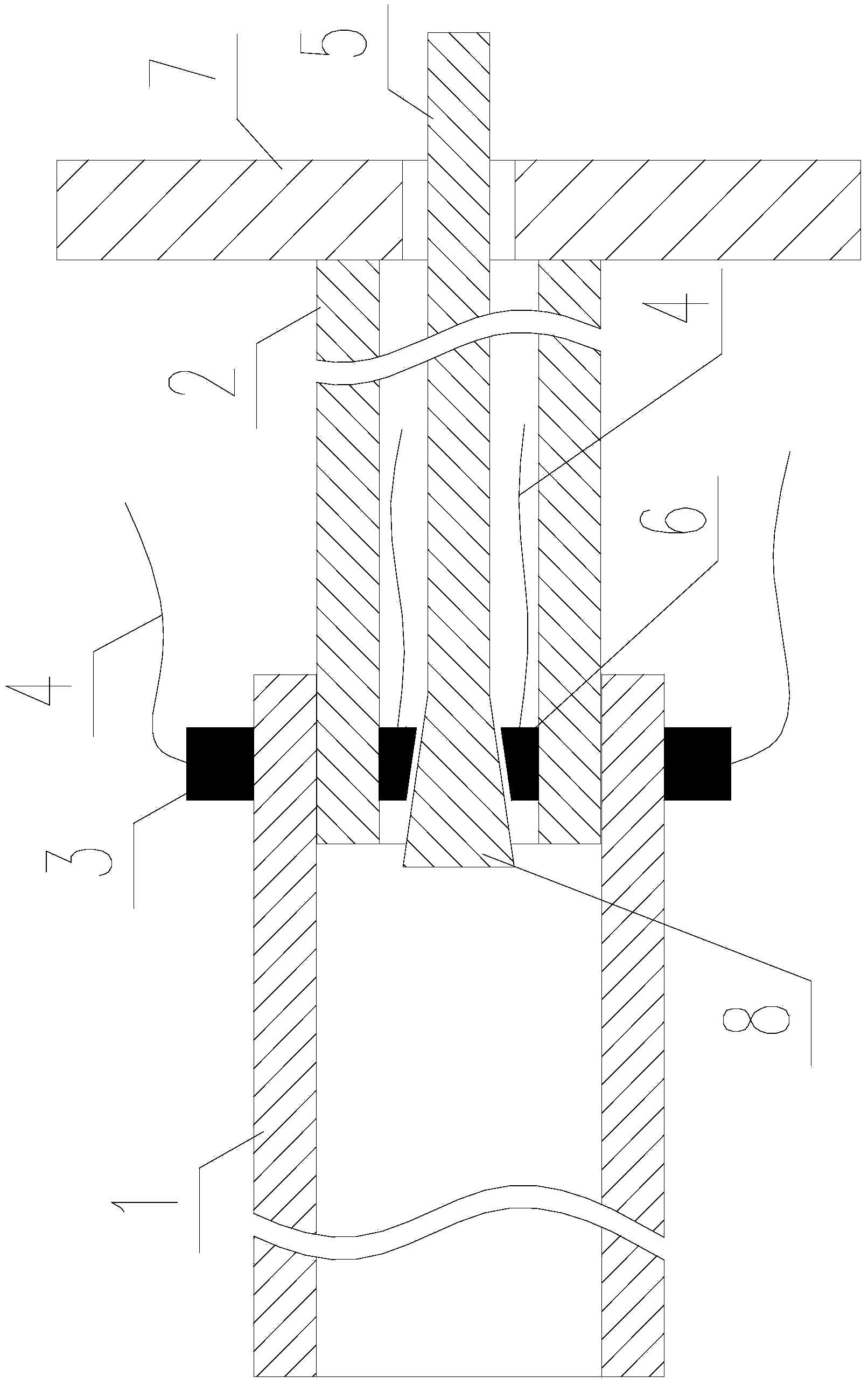

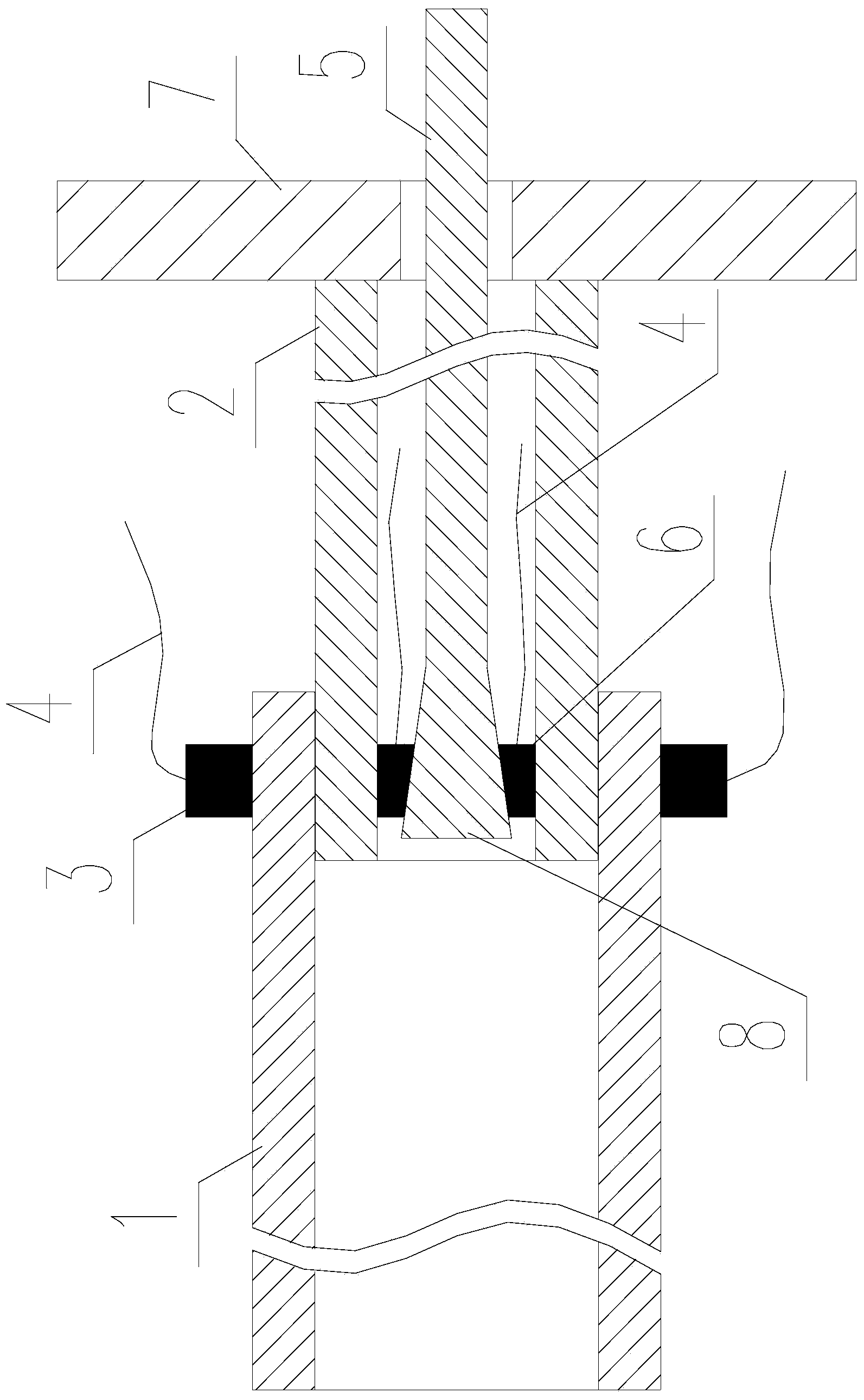

[0014] Example: such as figure 1 As shown, a welding tool for a copper pipe and a stainless steel pipe includes a T-shaped tie rod and a baffle plate, a T-shaped head is arranged on the T-shaped tie rod, an external electrode is arranged on the outside of the copper pipe to be welded, and the external electrode is connected to the power line; Internal electrodes are installed at the welding place inside the tube, and the internal electrodes are connected to the power line. The taper of the T-shaped head is 6-10 degrees, which is convenient for the T-shaped rod to exert pressure on the internal electrodes during welding; taper is also set on the internal electrodes. , the taper is consistent with the taper of the T-shaped head, so that the internal electrode is more uniform in force; the T-shaped tie rod is made of insulating material.

[0015] The method of using the above-mentioned welding tool to weld copper pipes and stainless steel pipes is as follows: (1) outside the copp...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap