Equipment for connecting dial gage

A dial indicator and equipment technology, used in metal processing equipment, measuring/indicating equipment, metal processing mechanical parts, etc., can solve the problem of falling off of the magnetic table and dial indicator, insufficient adsorption force of the magnetic table, and damage to the machine tool. , workpiece, people and other problems, to achieve the effect of convenient operation, simple structure, and reduce labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, but the scope of protection is not limited to the content described in this embodiment.

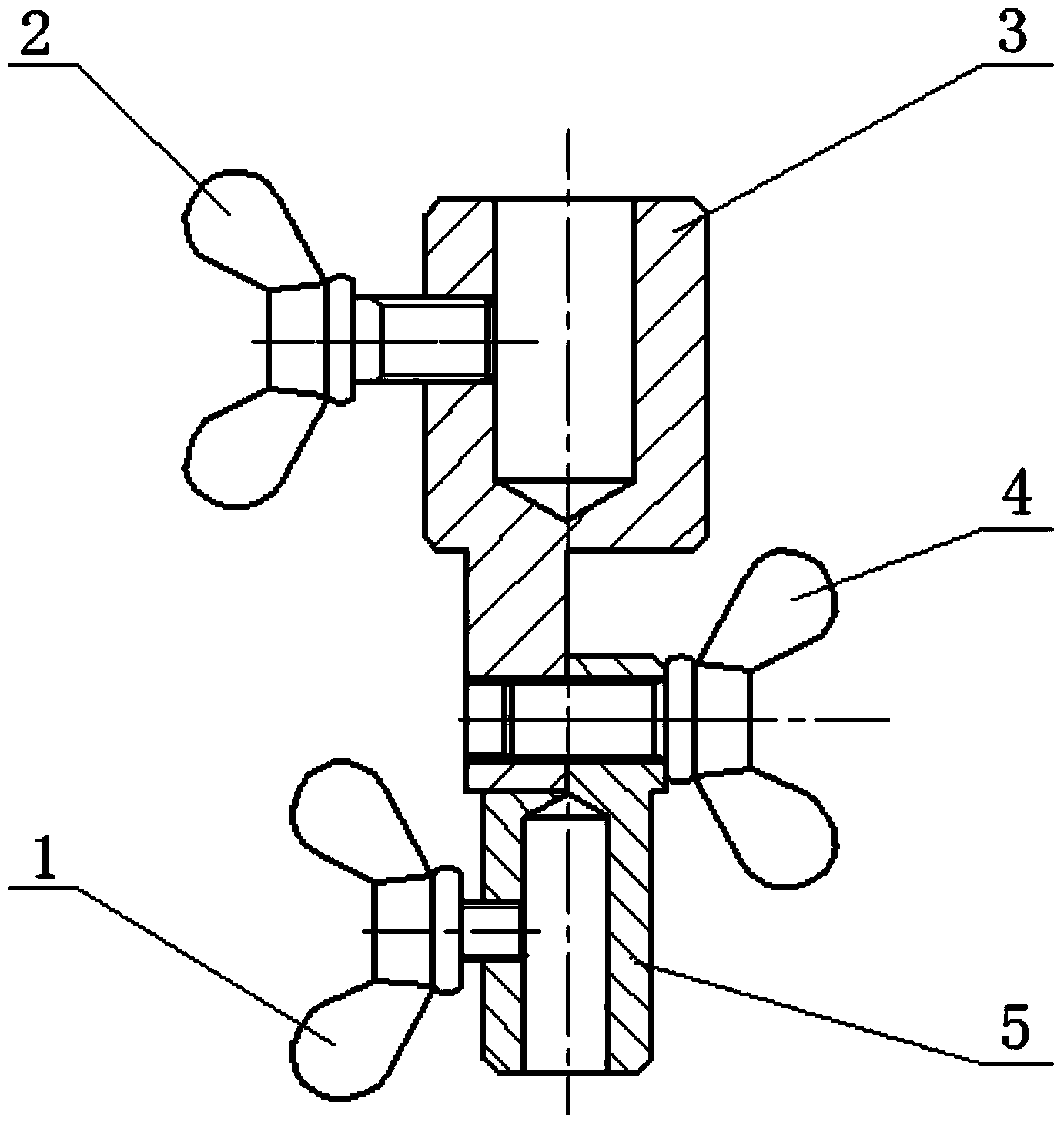

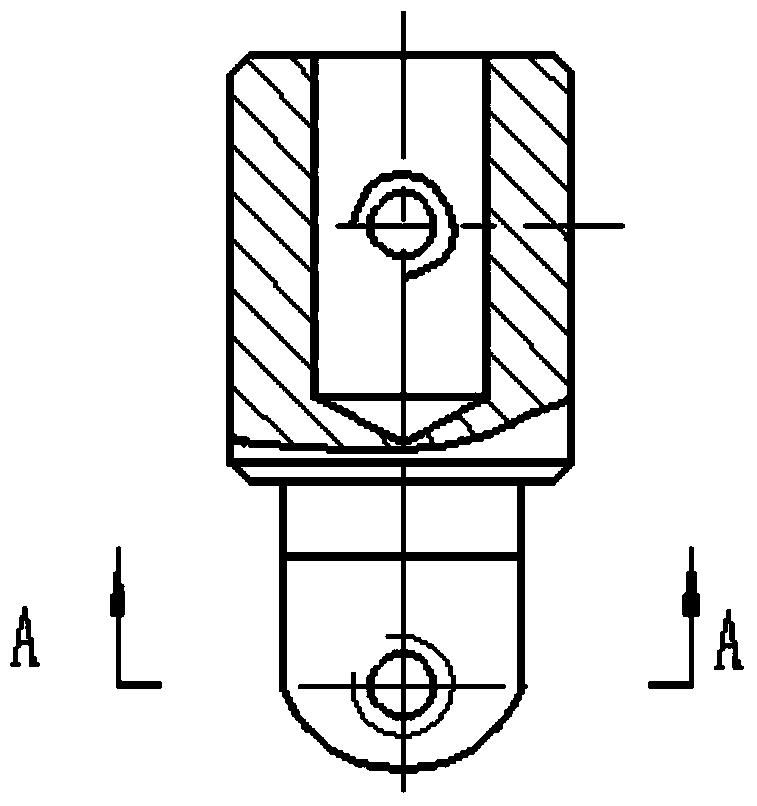

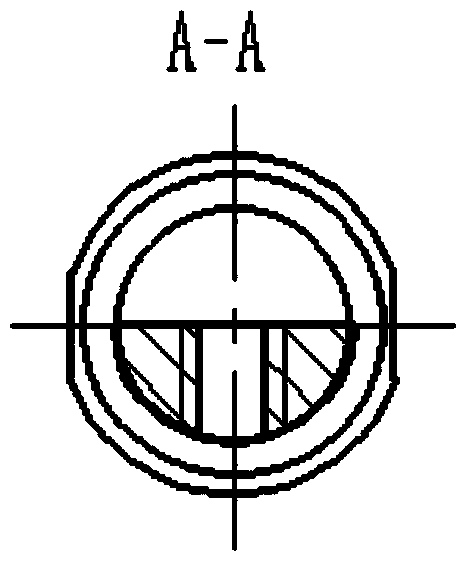

[0028] Such as Figure 1 to Figure 7 As shown, the present invention is a device for connecting a dial indicator, including a connecting sleeve I3 and a connecting sleeve II5, the connecting sleeve I3 and connecting sleeve II5 are connected by a butterfly bolt C4, and the connecting sleeve II5 can surround the butterfly bolt C4 Rotate to make the connection sleeve I3 and the connection sleeve II5 centerline direction form a certain angle, thereby expanding the measuring range of the lever dial indicator on the machine tool.

[0029] The device for connecting the dial indicator also includes a butterfly bolt B2 connecting the connecting sleeve I3 and the milling cutter, and a butterfly bolt A1 connecting the connecting sleeve II5 and the dial indicator.

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com