Flexible arc-shaped swing racking mechanism of face rod

An arc-shaped swing and flexible technology, applied in the direction of handling dough, conveyor objects, baking, etc., can solve problems such as easy to drop rods, low work efficiency, and poor running stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

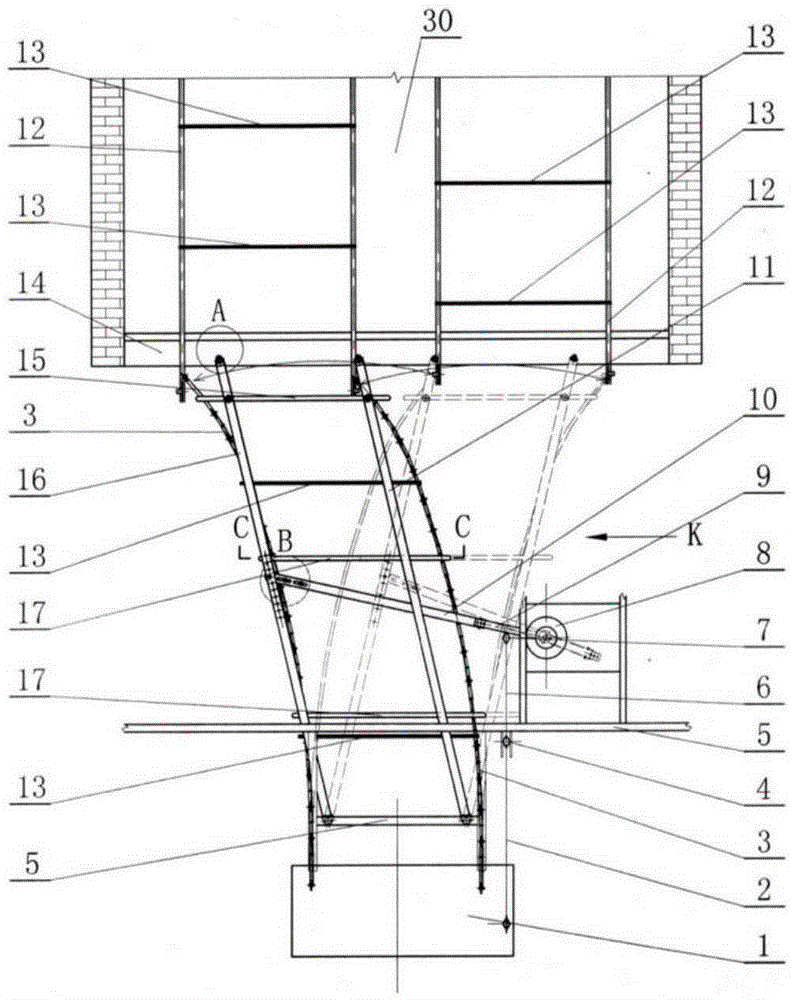

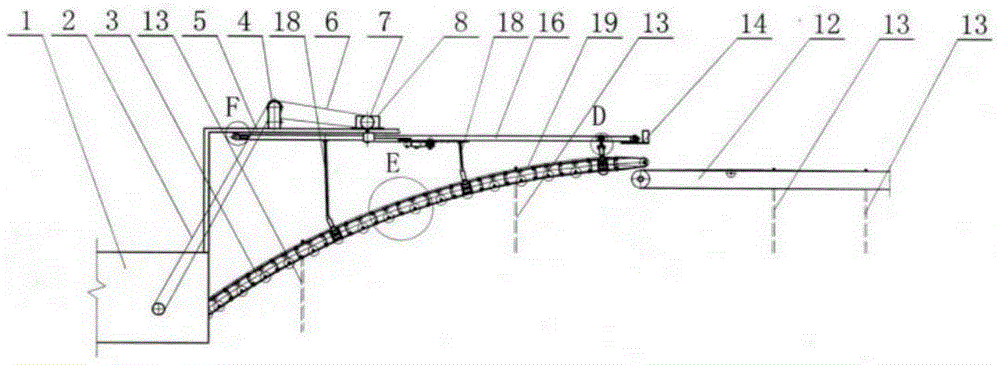

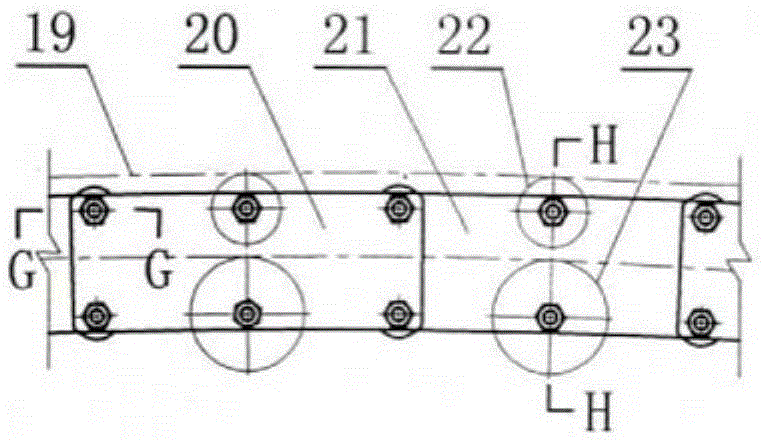

[0022] specific implementation plan

[0023] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0024] The noodle bar flexible arc swing racking mechanism of the present invention includes a flexible arc swing arm 3, a flexible arc swing arm fixed connecting rod 15 at the end, a flexible arc swing arm fixed connecting rod 17 in the middle, a reversing gear reducer 8, and a crank 9 , connecting rod 10, left swing rod 16, right swing rod 11 and swing rod roller guide rail 14, it is characterized in that: the flexible arc swing arm 3 provides one rod one rod vermicelli 13 simultaneously with the rod feeder 1 of the noodle machine host Swing, one rod by one rod of dried noodles 13 is alternately put on the dried noodle drying conveying chain 12 of the dried noodle drying chamber 30, the rod feeder 1 of the noodle machine host gives 1 to 50 rods of dried noodles per minute, and the flexible arc swing arm 3 also Then swi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com