An upper swivel crane suitable for low headroom workshops

A low headroom and crane technology, applied in the direction of walking bridge cranes, cranes, traveling mechanisms, etc., can solve the problems that the headroom height cannot be installed on the rotating crane, affect the economic benefits of the enterprise, increase the height of the factory building, etc., and achieve compact structure, shortened Renovation cycle and the effect of reducing investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described below in conjunction with the accompanying drawings, but the present invention is not limited in any way, and any transformation made based on the teaching of the present invention falls within the protection scope of the present invention.

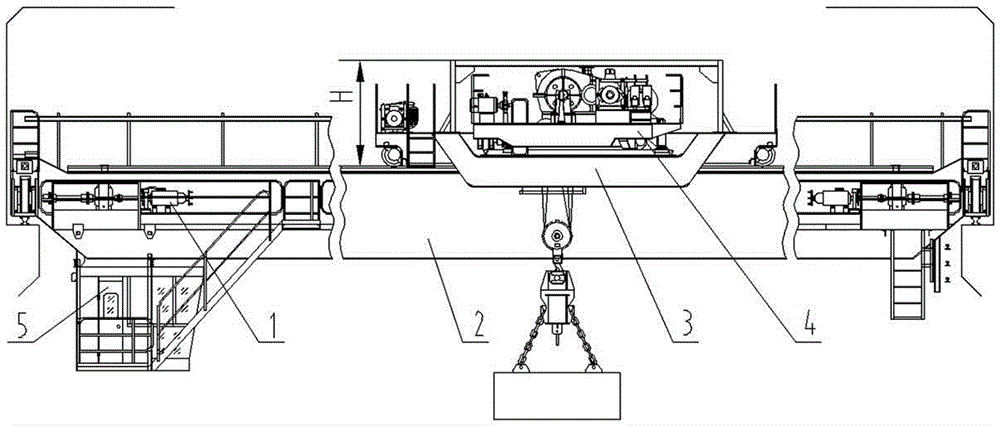

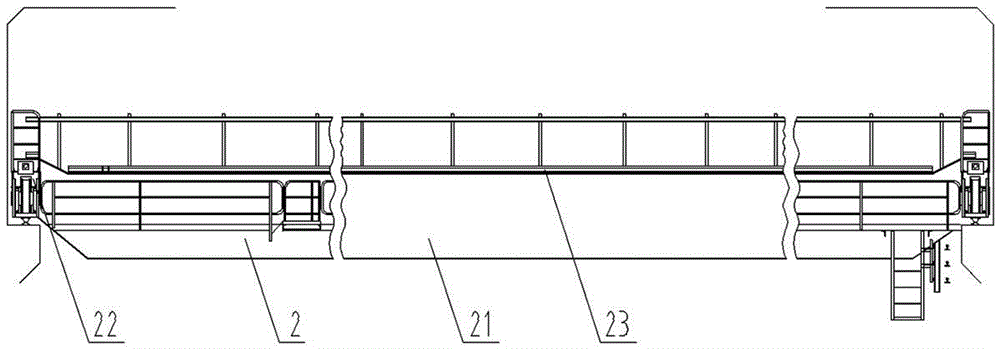

[0012] Such as Figure 1~3 As shown, the present invention includes a cart running mechanism 1, a bridge frame 2, a lower trolley 3, an upper trolley 4, and an electrical device 5. The end beam 22 of the bridge frame 2 is provided with a cart running mechanism 1; The lower trolley 3 is arranged above the main girder 21; the electrical equipment 5 is arranged on the bridge frame 2; the lower trolley 3 adopts a concave structure in the middle; the upper trolley 4 is arranged above the lower trolley 3; the bridge frame The upper surface of the main beam 21 of 2 is lower than the upper surface of the end beam 22.

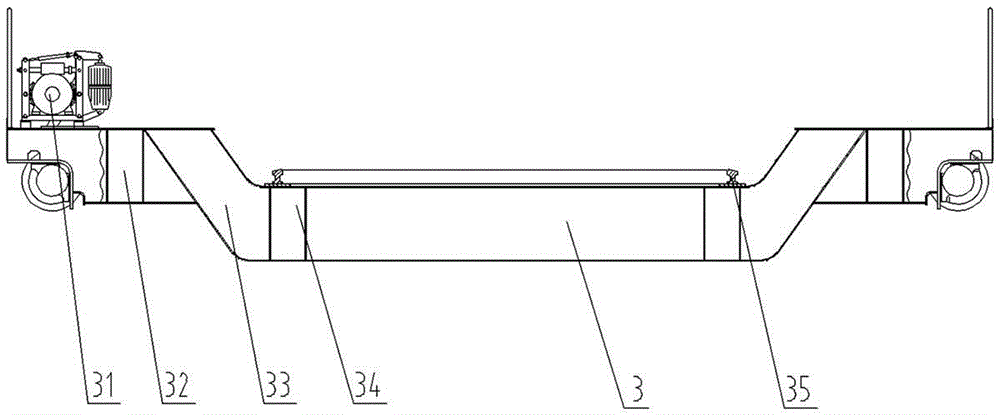

[0013] The lower trolley 3 includes a lower trolley running mechanism 31,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com