Roof energy-saving automatic melted snow collecting system

A collection system and snow-melting technology, which is applied in snow traps and other directions, can solve the problems of low automation, poor work reliability, and low snow removal efficiency, and achieve the effects of reasonable structure, improved work reliability, and improved snow removal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

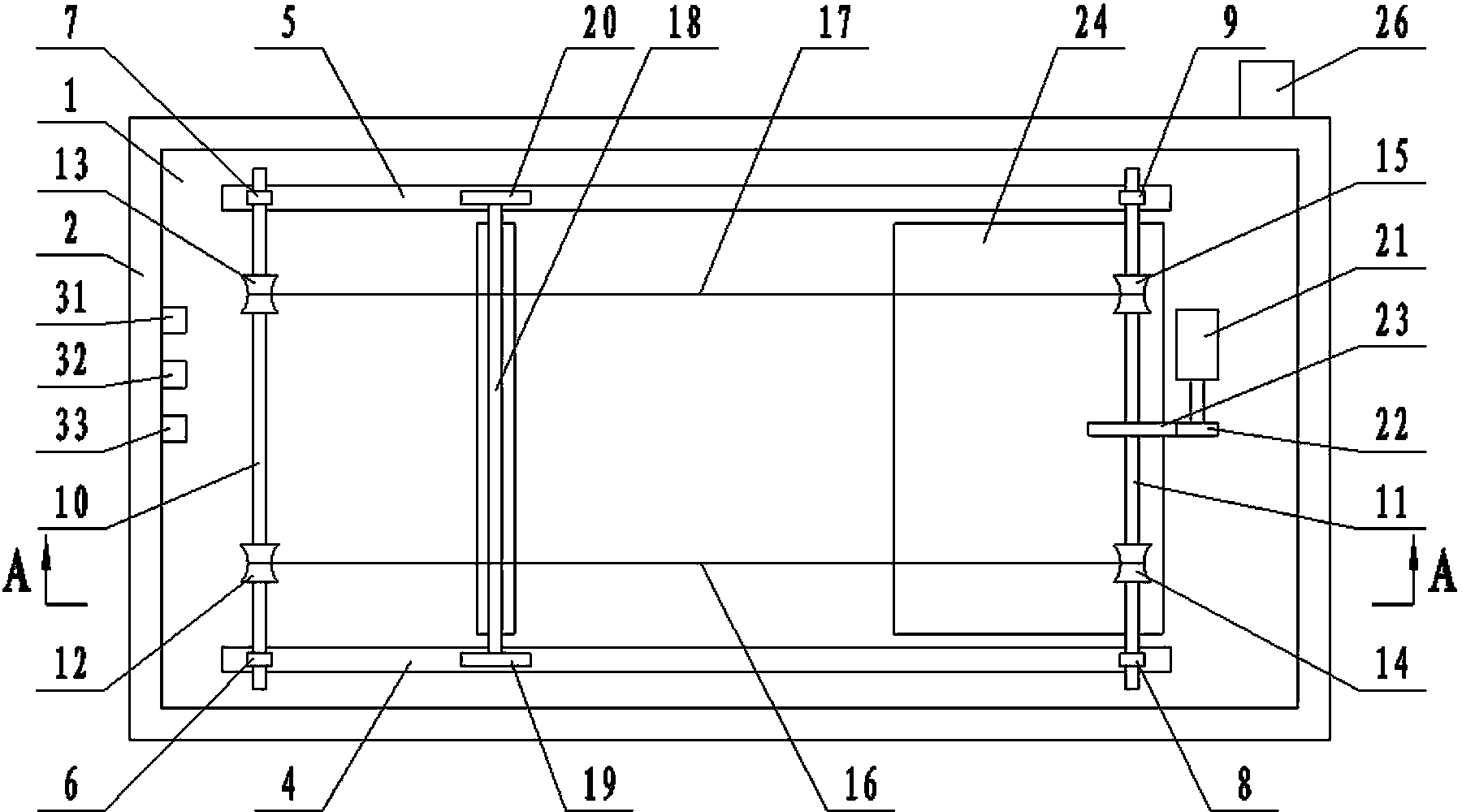

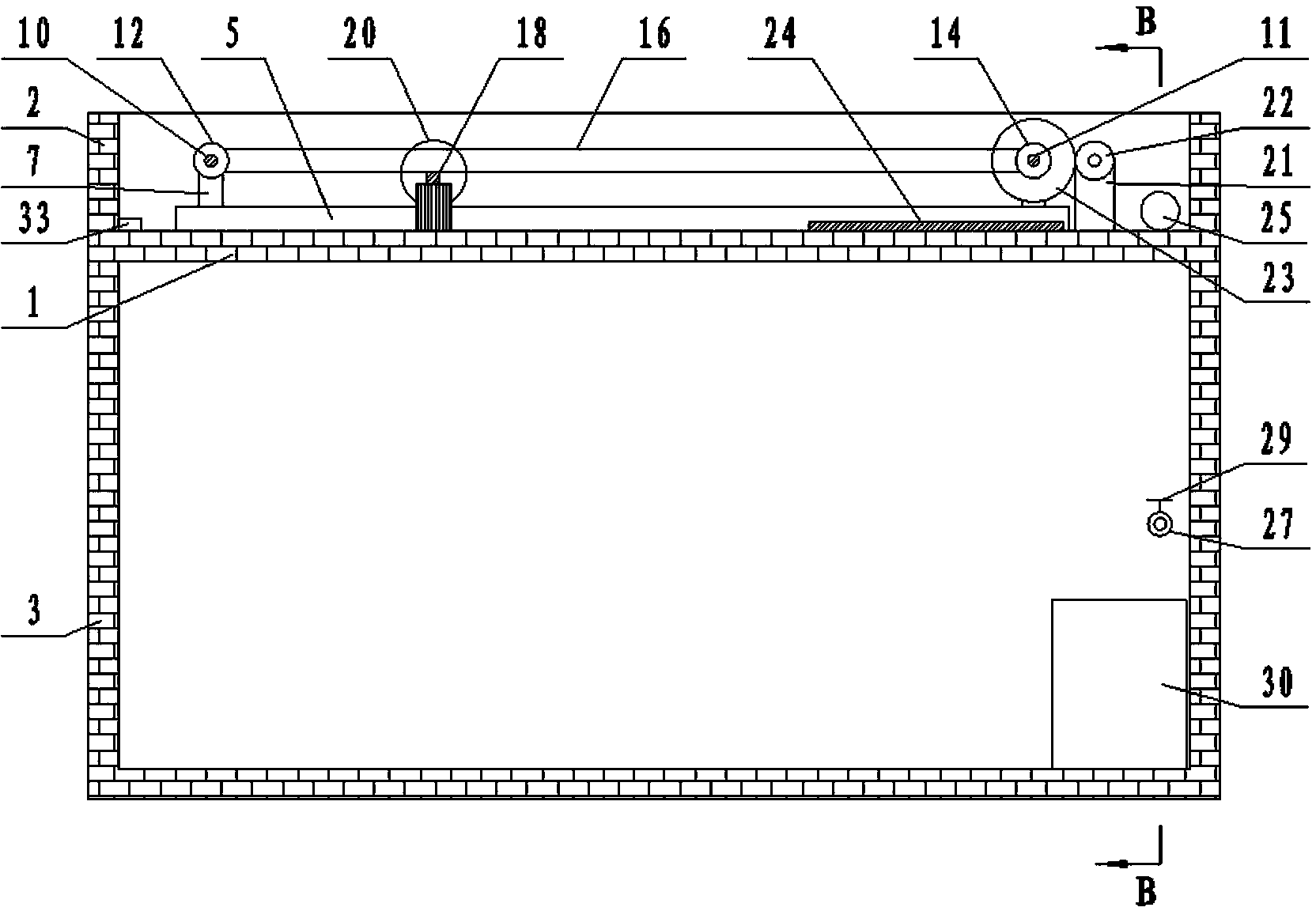

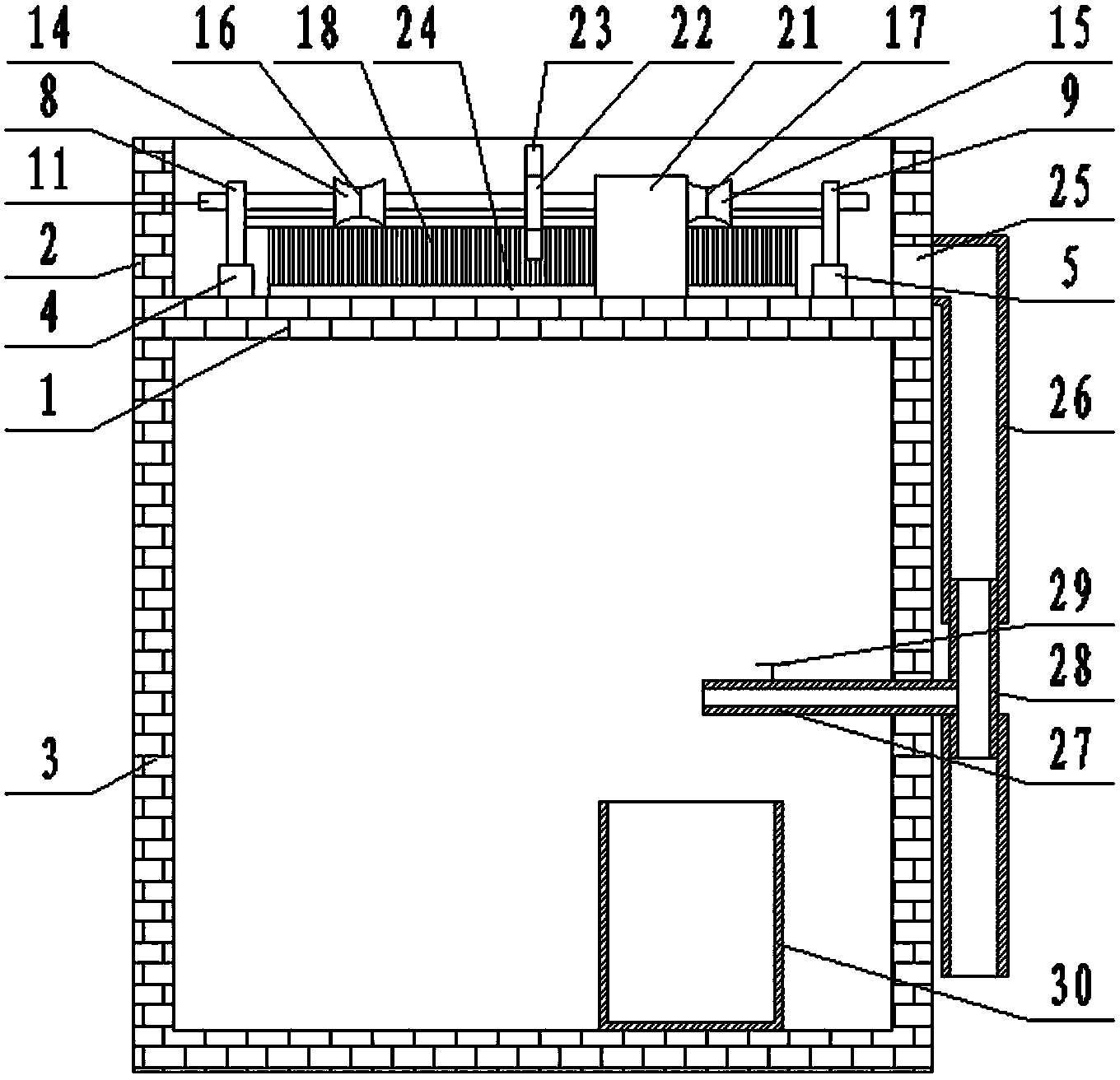

[0013] An energy-saving automatic snowmelt collection system on the roof, including a main part of the house, a snow removal part on the roof, a melting water collection part, and a sensor control part;

[0014] The main part of the house includes a roof 1, a parapet wall 2, and an outer wall 3;

[0015]The roof snow removal part includes a first track 4, a second track 5, a first bearing seat 6, a second bearing seat 7, a third bearing seat 8, a fourth bearing seat 9, a first pulley shaft 10, and a second pulley shaft 11. The first fixed pulley 12, the second fixed pulley 13, the third fixed pulley 14, the fourth fixed pulley 15, the first wire rope loop 16, the second wire rope loop 17, the snow removal brush 18, the first roller 19, the second roller 20. Two-way motor 21, pinion 22, large gear 23, mica heating plate 24; the first track 4 is laid and fixed on the front edge of the upper surface of the roof 1; the second track 5 is laid and fixed on the rear edge of the upper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com