Protective window and manufacturing method thereof

A production method and technology of protective windows, applied in the direction of blinds/movable grilles, etc., can solve problems such as single structural effect, poor durability, easy to rust and rot, etc., and achieve strong durability and weather resistance, strong structural toughness, and random and rich shapes Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

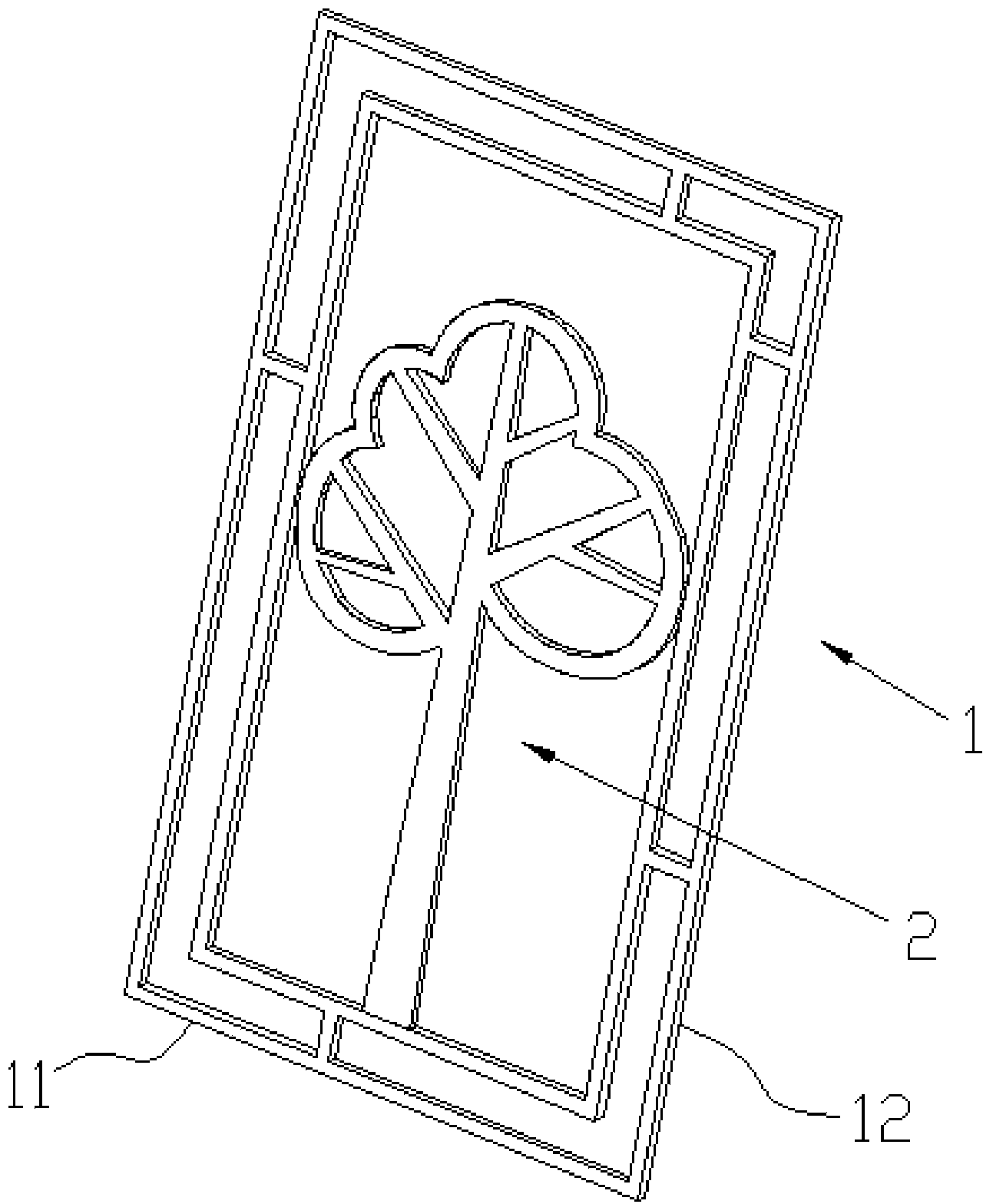

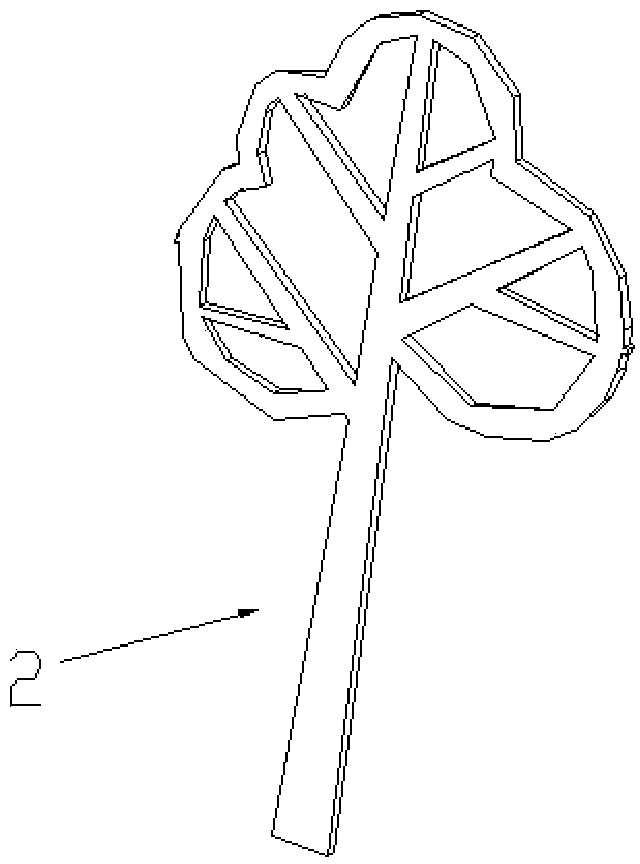

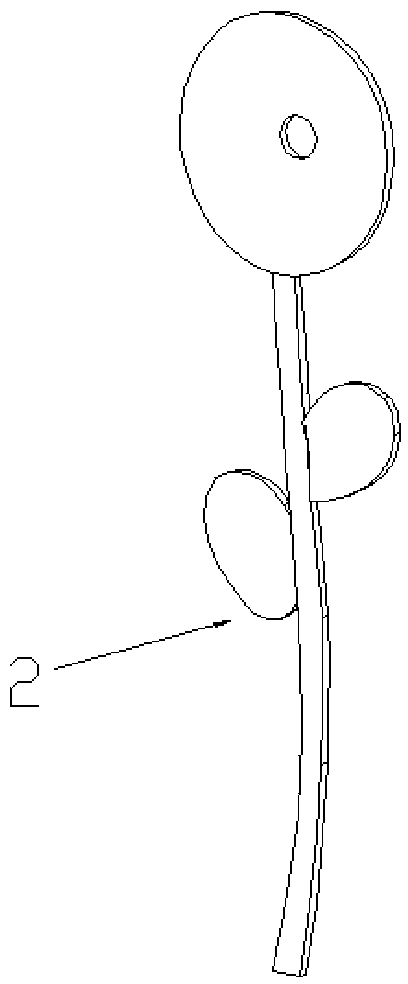

[0027] figure 1 Schematically shows a protective window according to an embodiment of the present invention, consisting of an outer frame 1 and a decorative part 2, such as image 3 As shown, the outer frame 1 is composed of horizontal aluminum profiles 11 arranged horizontally and vertical aluminum profiles 12 arranged vertically and vertically to form a mesh frame structure through welding. As shown in Figure 2, the decorative parts 2 have shapes similar to trees and flowers. The decorative part 2 is prepared by high-energy laser cutting, sheet metal stamping, CNC machine tool processing or die casting according to the designed pattern, and then the decorative part 2 is placed in the outer frame 1, and the decorative part 2 is welded to the outer frame 1 fixed together. The outer surfaces of the outer frame 1 and the decorative part 2 are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com