Film-cooled turbine blade for fluid machinery

A technology of turbine blades and fluid machinery, applied in the direction of mechanical equipment, blade support components, engine components, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

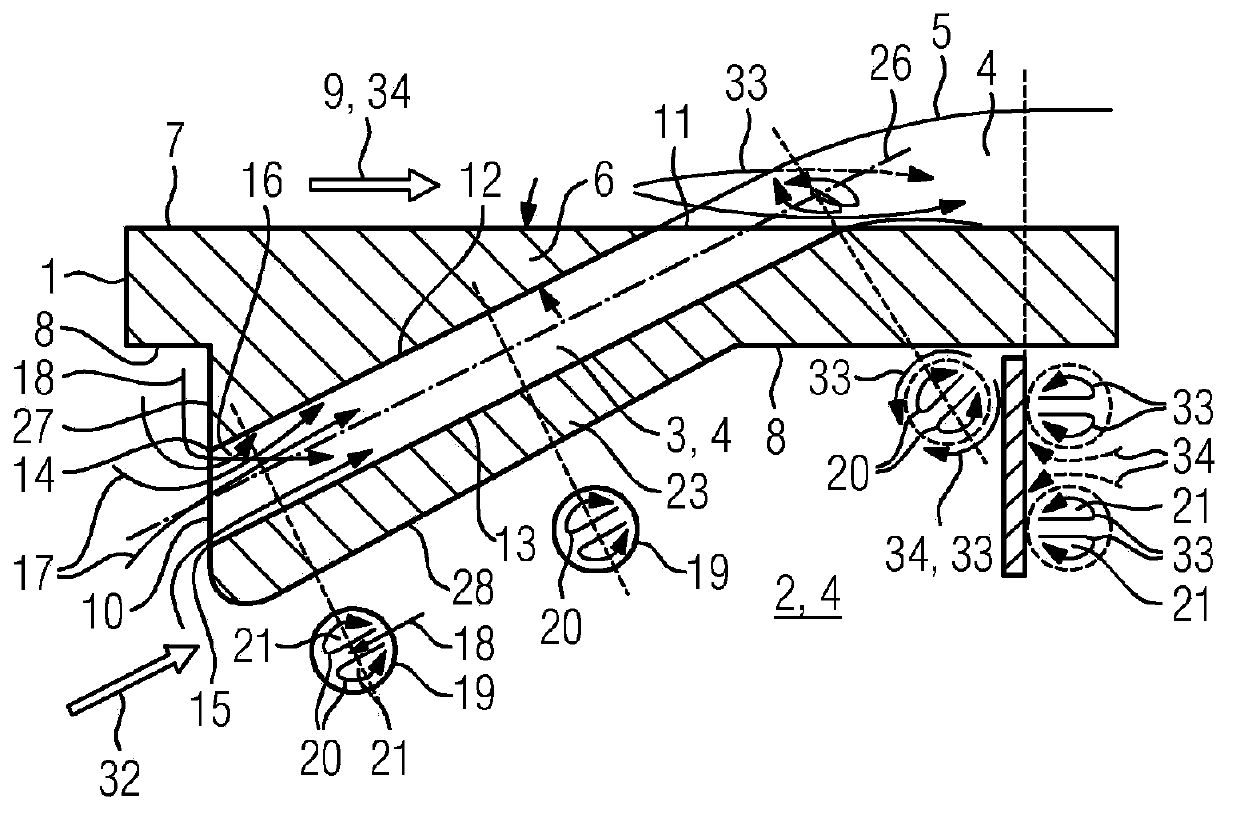

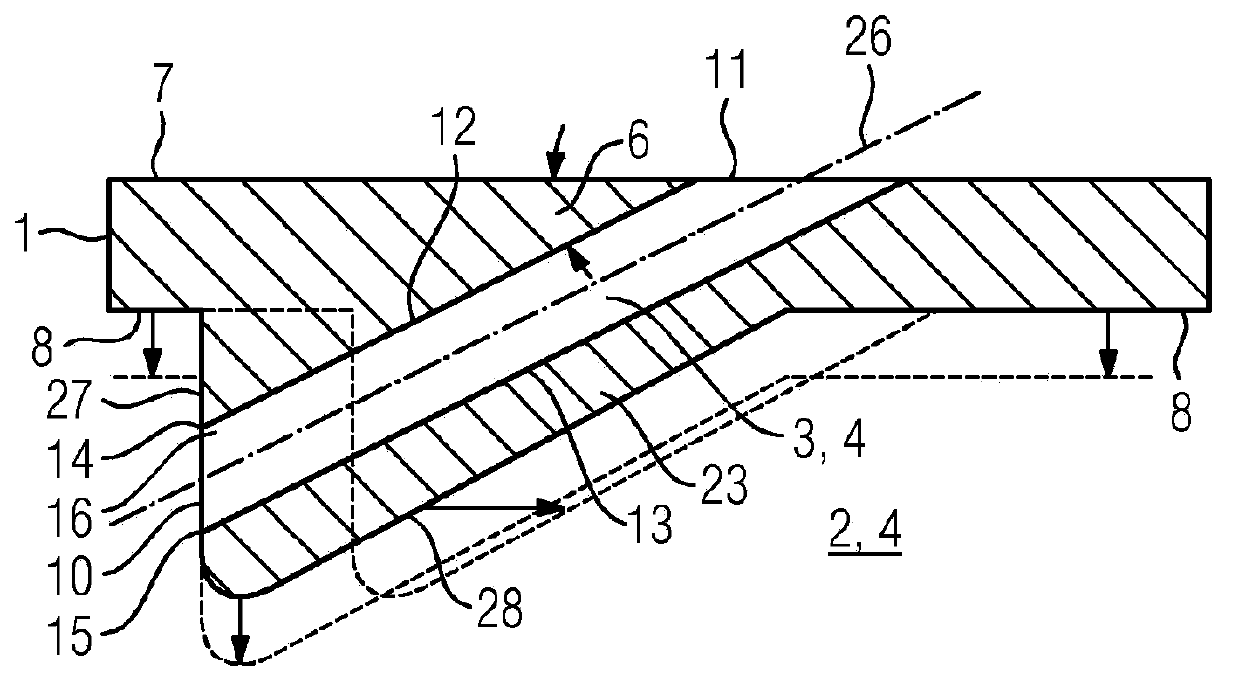

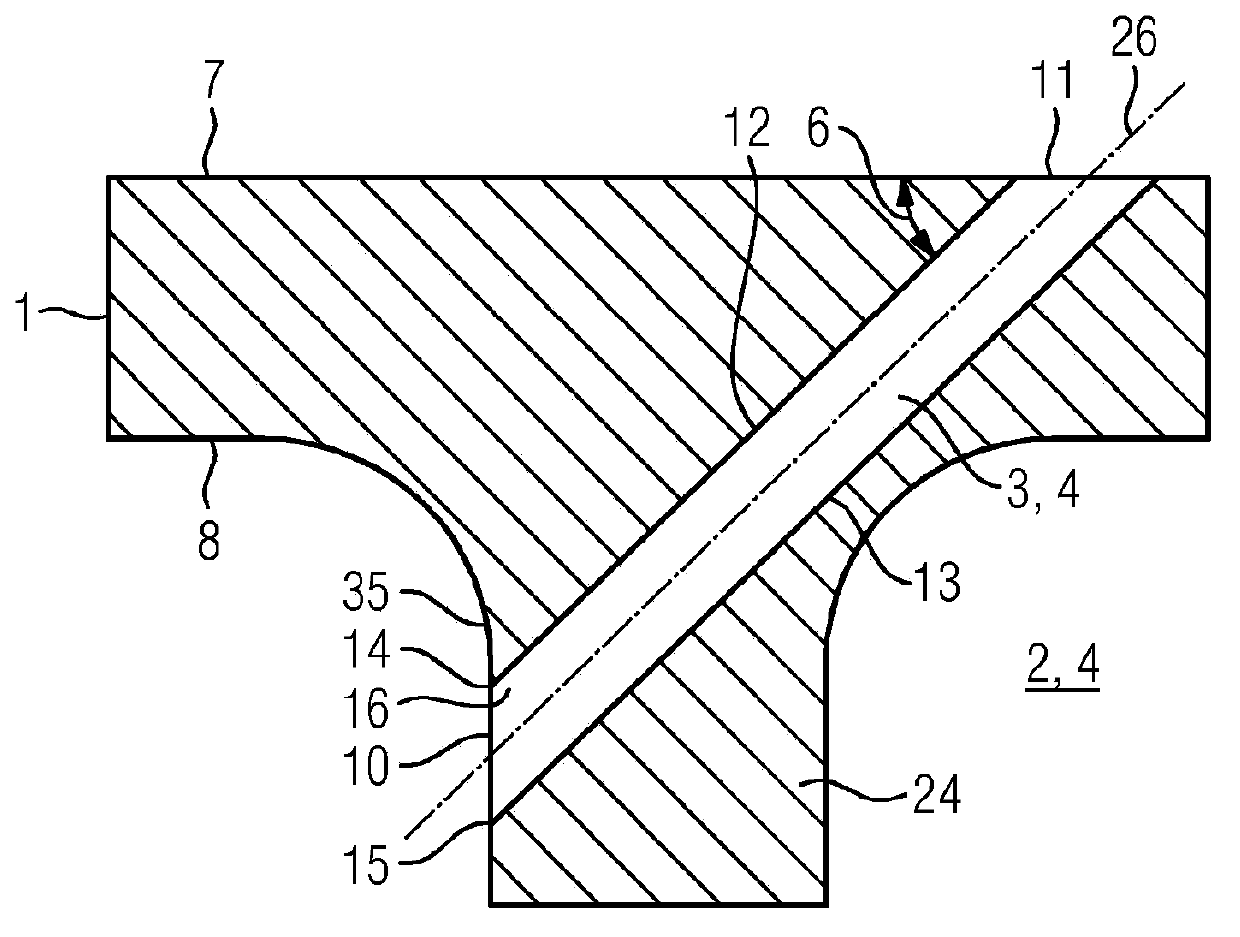

[0020] Figures 1 to 6 A sectional view of the outer wall 1 of a turbine blade of a fluid machine is shown. The outer wall 1 delimits the inner cavity 2 and has an outer side 7 and an inner side 8 . During hydromechanical operation, a hot gas flow 34 occurs on the outer side 7 with a hot gas main flow direction 9 parallel to the outer side 7 , which is directed towards the trailing edge (not shown in the figure) of the turbine blade. A continuous channel 3 with a circular cross section 19 is introduced into the outer wall 1 , which is inclined in the through-flow direction directed from the inside to the outside relative to the trailing edge of the turbine blade and encloses a sharp angle of inclination 6 with the outer side 7 .

[0021] Figures 1 to 6 The continuous channel 3 in has an inlet 10 on the inside and an outlet 11 on the outside. Furthermore, the continuous channel 3 has an axis 26 , an upstream side 12 and a downstream side 13 . The inlet 10 of the continuou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com