Container type moving pump station

A container type, pump station technology, applied in the direction of variable capacity pump components, pumps, pump control, etc., can solve the problems of large area of the pump station, affecting preparation time, pipeline leakage, etc., to reduce work intensity, improve Mobility performance, noise reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

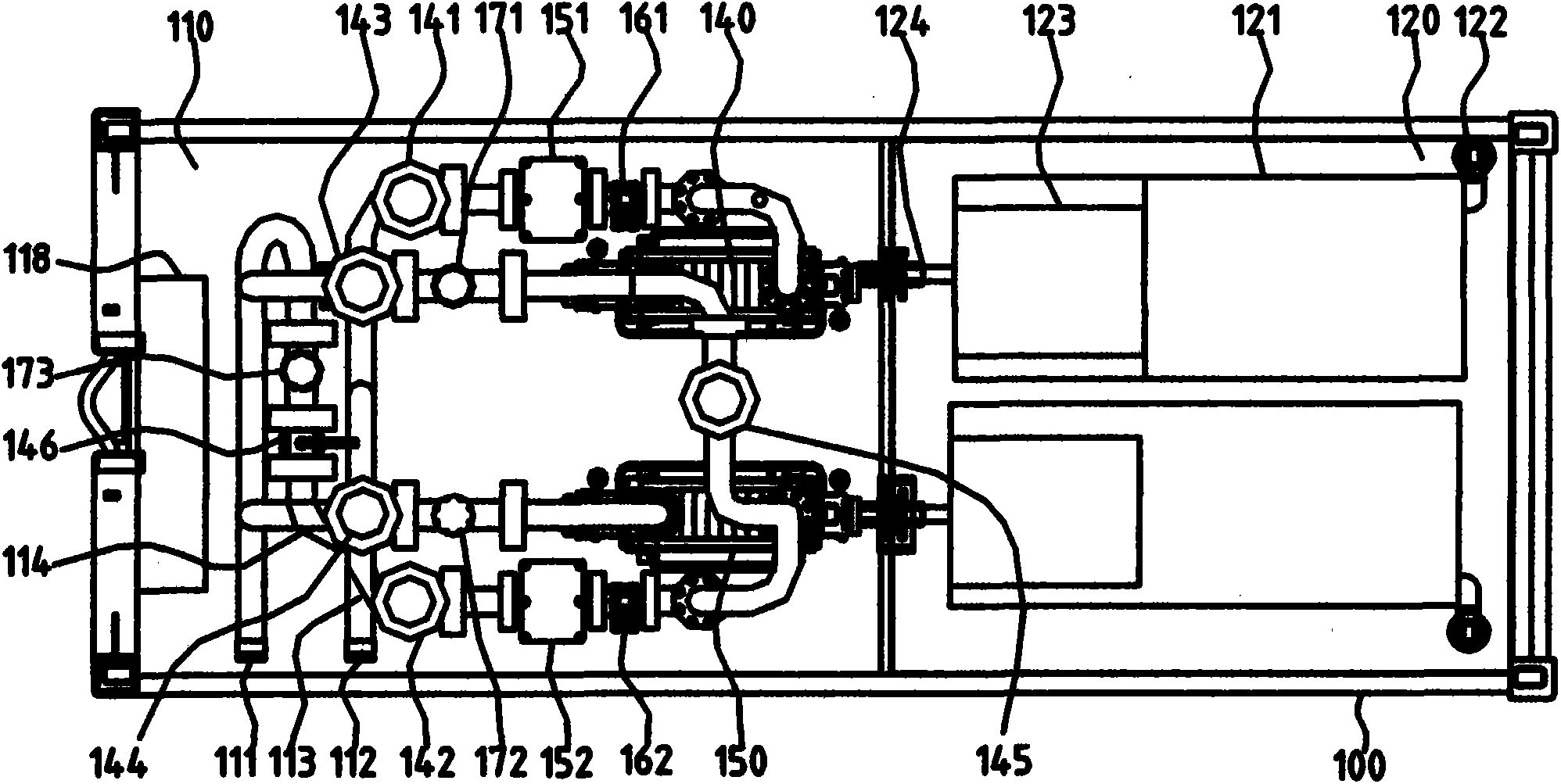

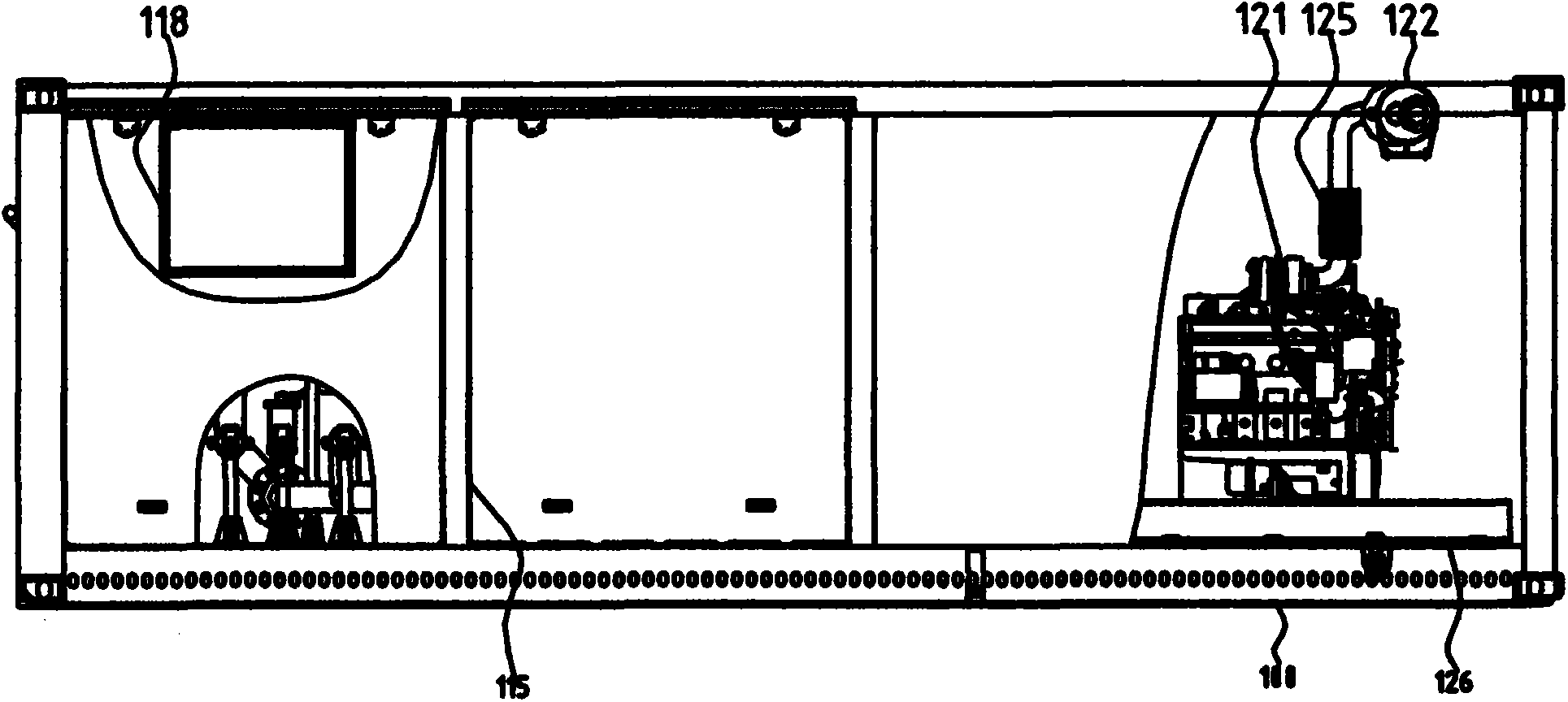

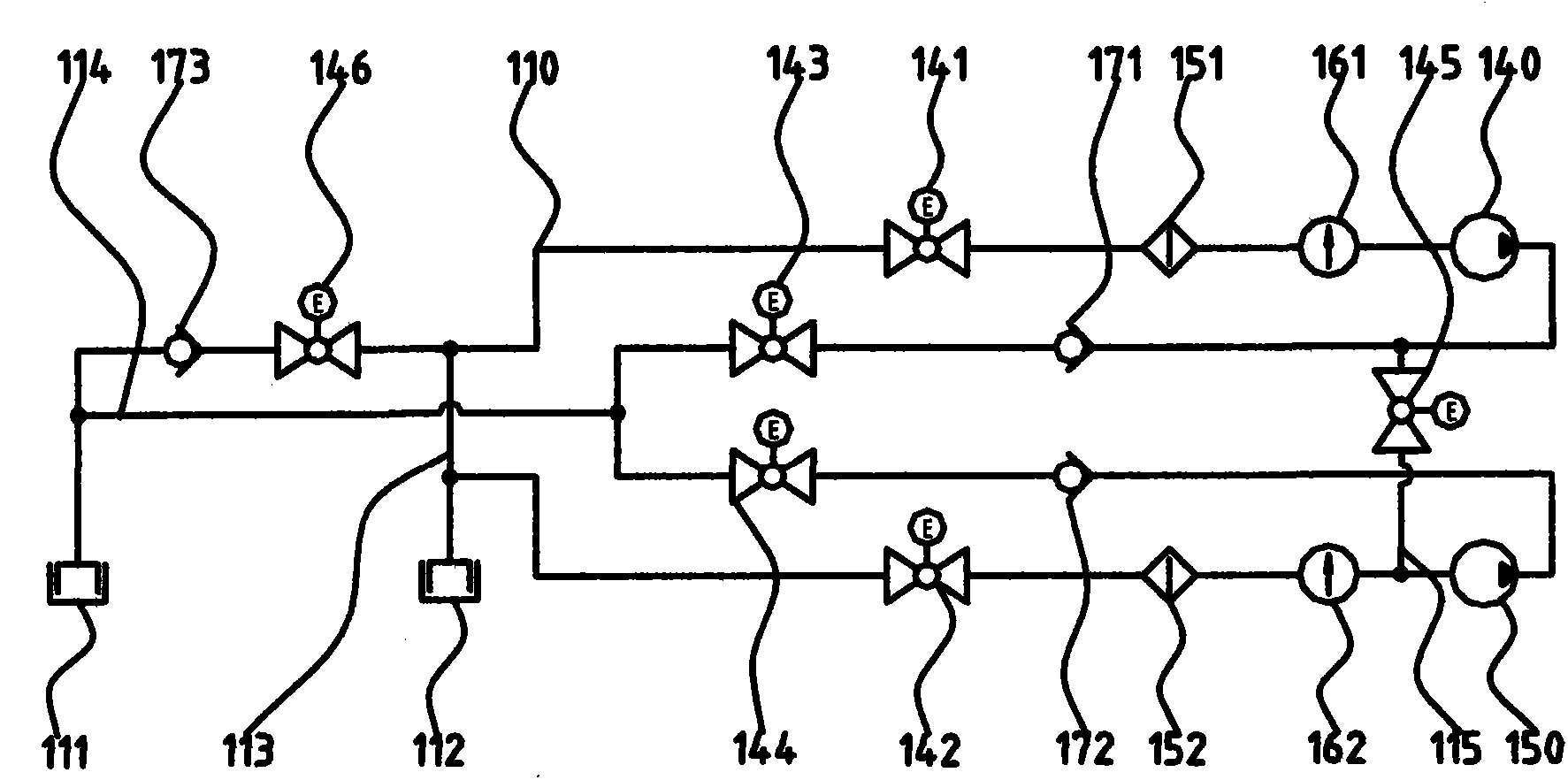

[0034] figure 1 It is a schematic diagram of the installation structure of a container-type mobile pump station according to an embodiment of the present invention. Generally, it includes a box frame 100, and the box frame 100 can be axially spaced into: a nacelle 120, installed with a power source 121 for providing power for the pumping station. The pump room 110 can install two oil pumps and connect two oil pumps to realize the oil delivery pipelines of three different oil delivery modes: single pump, double pumps in series, and double pumps in parallel. The oil delivery pipeline can be provided with outlet ports 111 and Inlet port 112 . The oil pumps may be connected to the power sources 121 respectively. A console 118 which is respectively connected to the pump room 110 and the engine room 120 and controls the working process of the pump room 110 and the engine room 120 is installed on the side away from the engine room 120 . In the present invention, two oil pumps are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com