Photoresist removing method

A photoresist and photoresist technology, applied in electrical components, semiconductor/solid-state device manufacturing, circuits, etc., can solve the problem of polluting the internal environment of the reaction chamber, and achieve the effect of purifying the internal environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

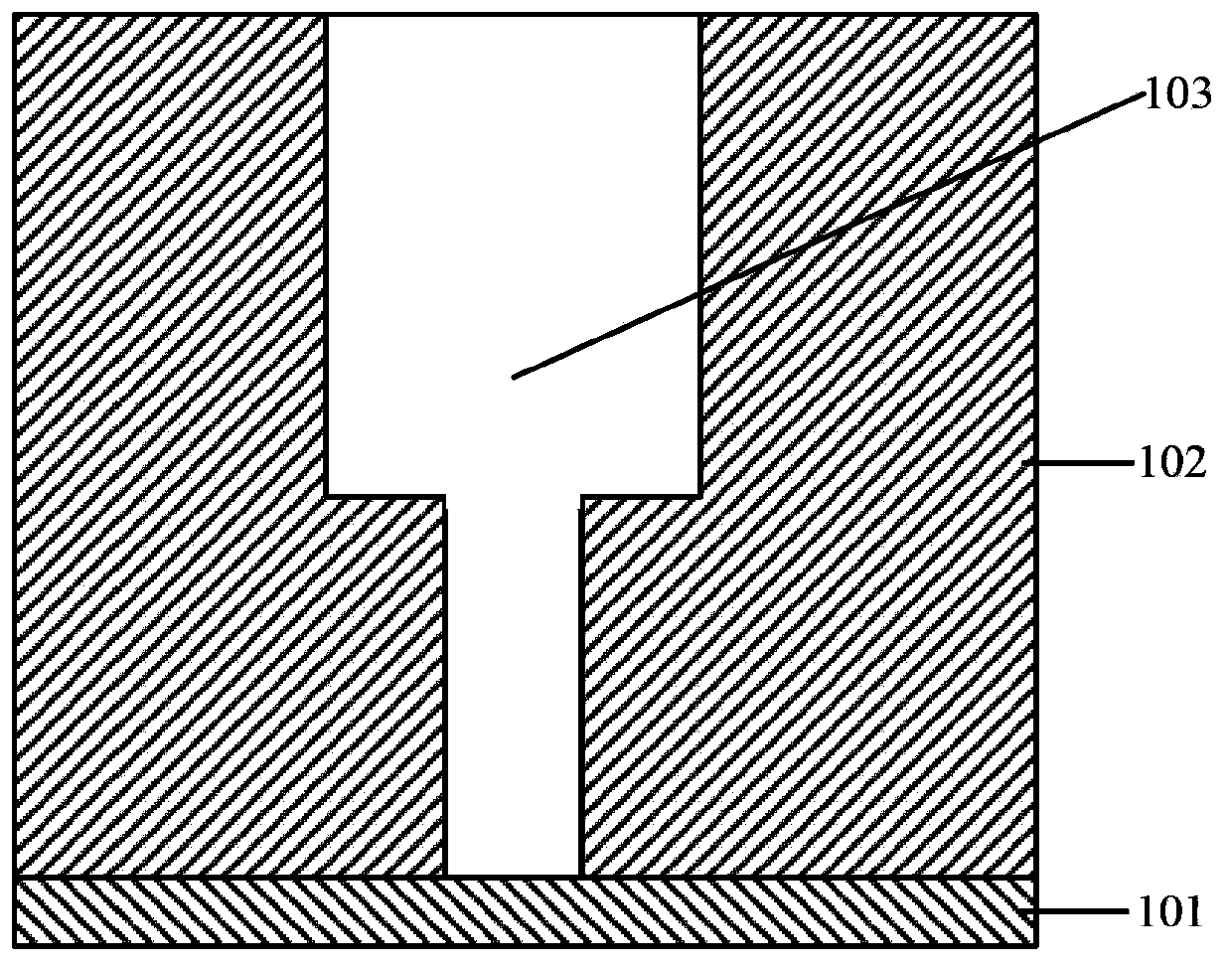

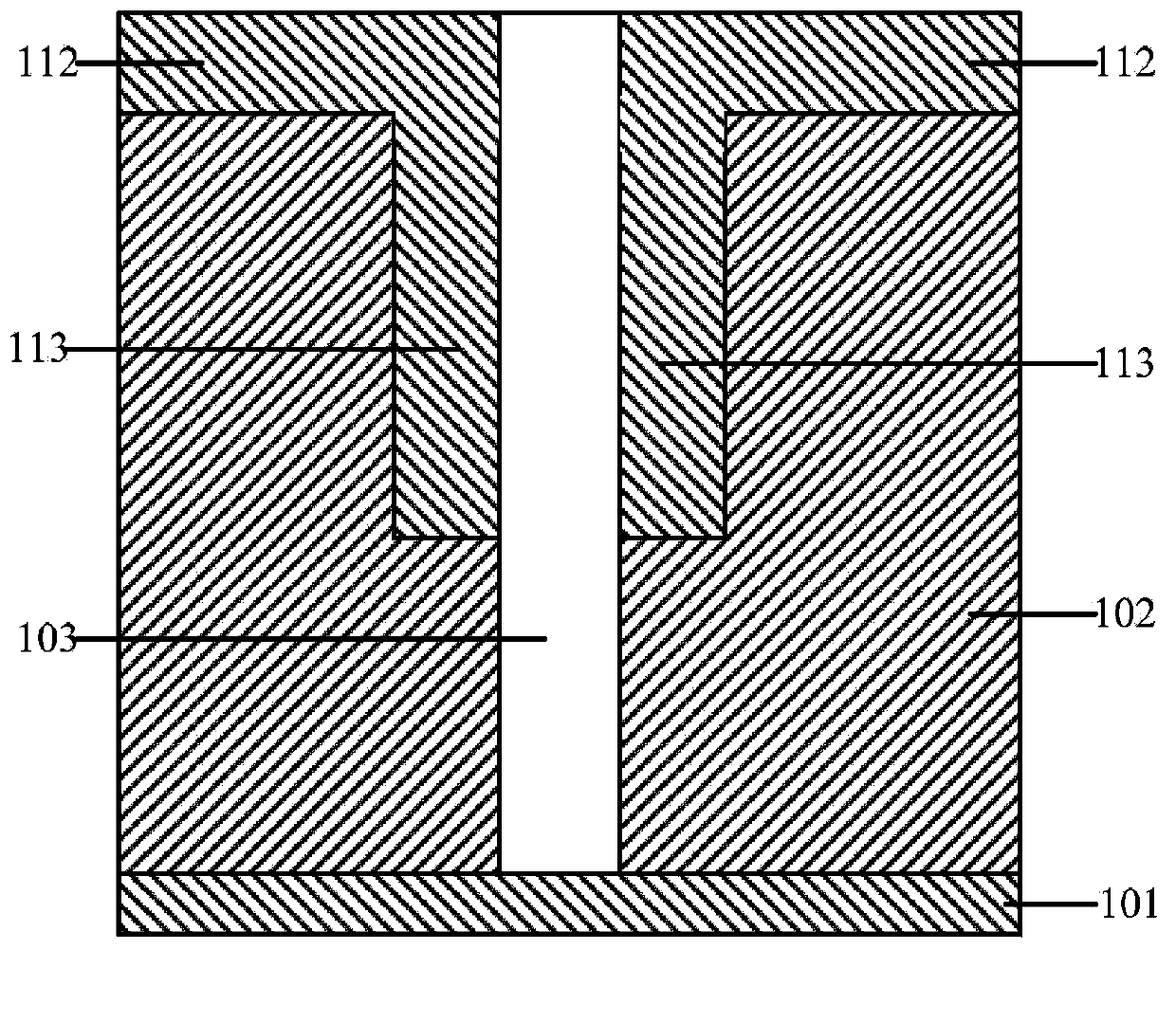

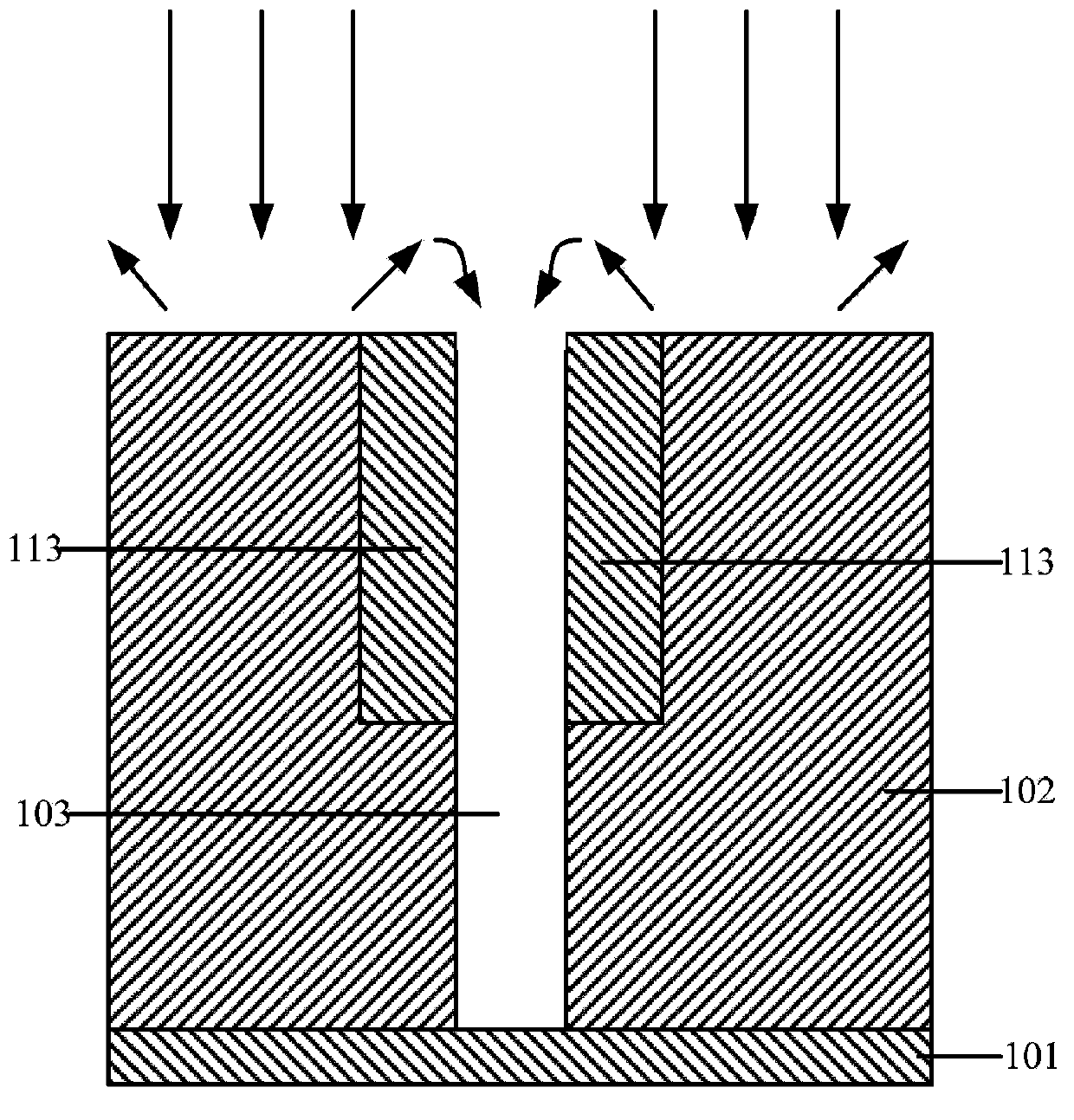

[0037]The implementation of the present invention will be described in detail below in conjunction with the drawings and examples, so that the realization process of how to use technical means to solve technical problems and achieve technical effects in the present invention can be fully understood and implemented accordingly.

[0038] In the following embodiments of the present invention, during the process of forming the etching opening, in the intermediate step plasma treatment process, while removing part of the photoresist in the sidewall of the etching opening, the photoresist in the previous plasma treatment process is also removed. The sputtered dielectric particles are deposited on the surface of the photoresist, and all the photoresist remaining on the sidewall of the etching opening is removed in the final plasma treatment, so as to complete the removal of the photoresist in the process of etching the opening. In addition, since the dielectric particles sputtered ont...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com