Cell unit having expansion burst region

A battery unit and area technology, applied in the direction of electrical components, secondary batteries, battery pack components, etc., to achieve the effects of reducing costs, increasing service life, and improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

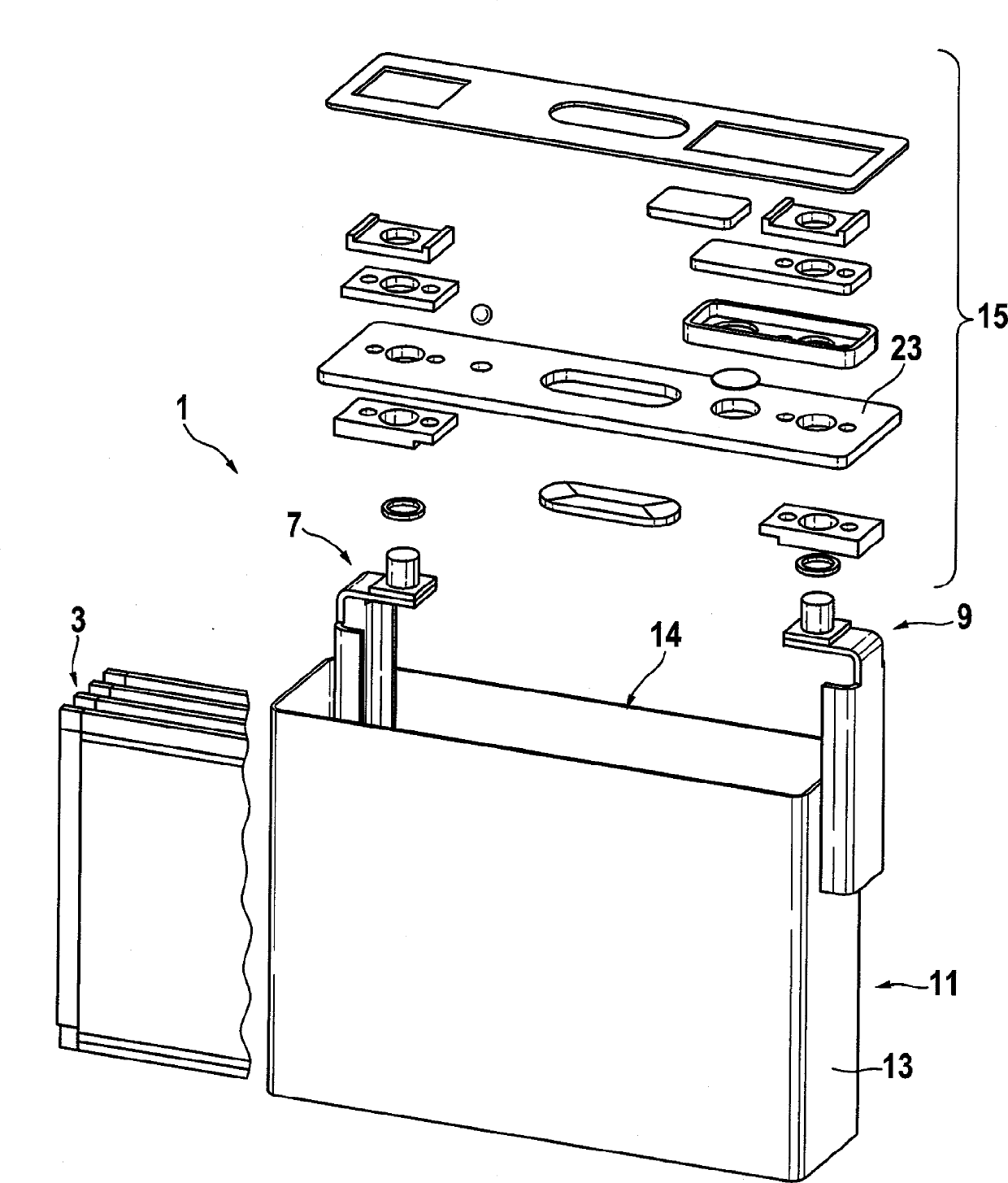

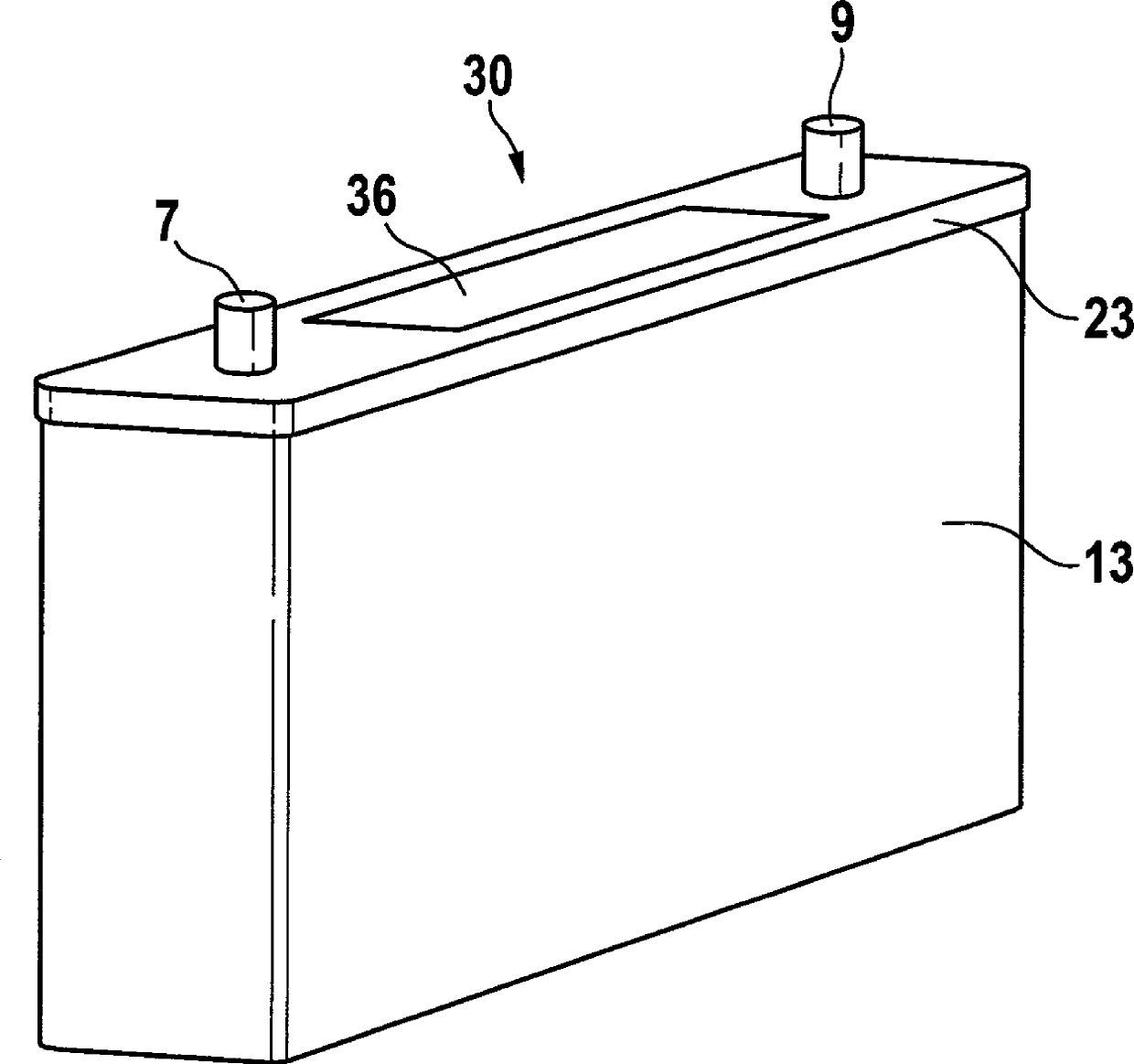

[0051] figure 1 An exploded view of a conventional Li-ion battery cell is shown. It can be seen that the battery cell is composed of a large number of individual components. Only the components and their features required for understanding the embodiments of the present invention are described here, and the remaining components of the battery unit are not described.

[0052] The battery cell 1 has at least one winding element 3 comprising a wound stack of a copper foil, an aluminum foil and a plastic film between them.

[0053] A current collector 7 made of copper is welded onto the raised region of the copper foil so that it is electrically connected to the anode of the winding element. A second current collector 9 made of aluminum is welded to an oppositely raised region of the aluminum foil in order to produce an electrical contact with the cathode of the winding element 3 . The current collectors 7 and 9 serve to electrically connect the battery cells to external compon...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com