Obstacle-crossing mechanical arm suitable for power transmission line inspection robot

A technology for inspection robots and transmission lines, applied in the field of inspection robots, can solve the problems of robots crossing obstacles and falling off transmission lines, difficulty in ensuring the stability of walking over obstacles, and reducing the stability of transmission lines, etc., so as to save labor costs, Simple structure and the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] A kind of embodiment of the present invention is described specifically below in conjunction with accompanying drawing:

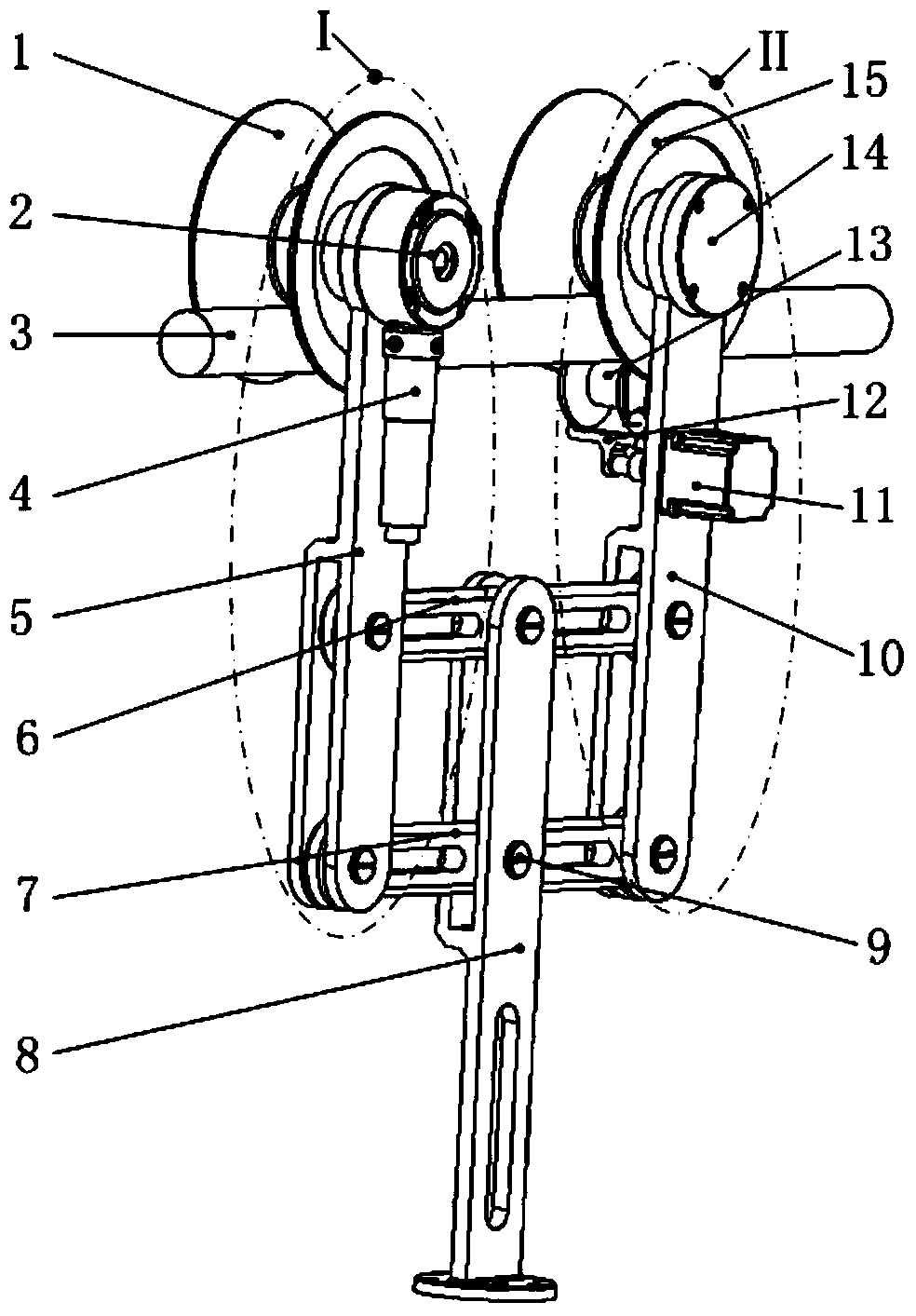

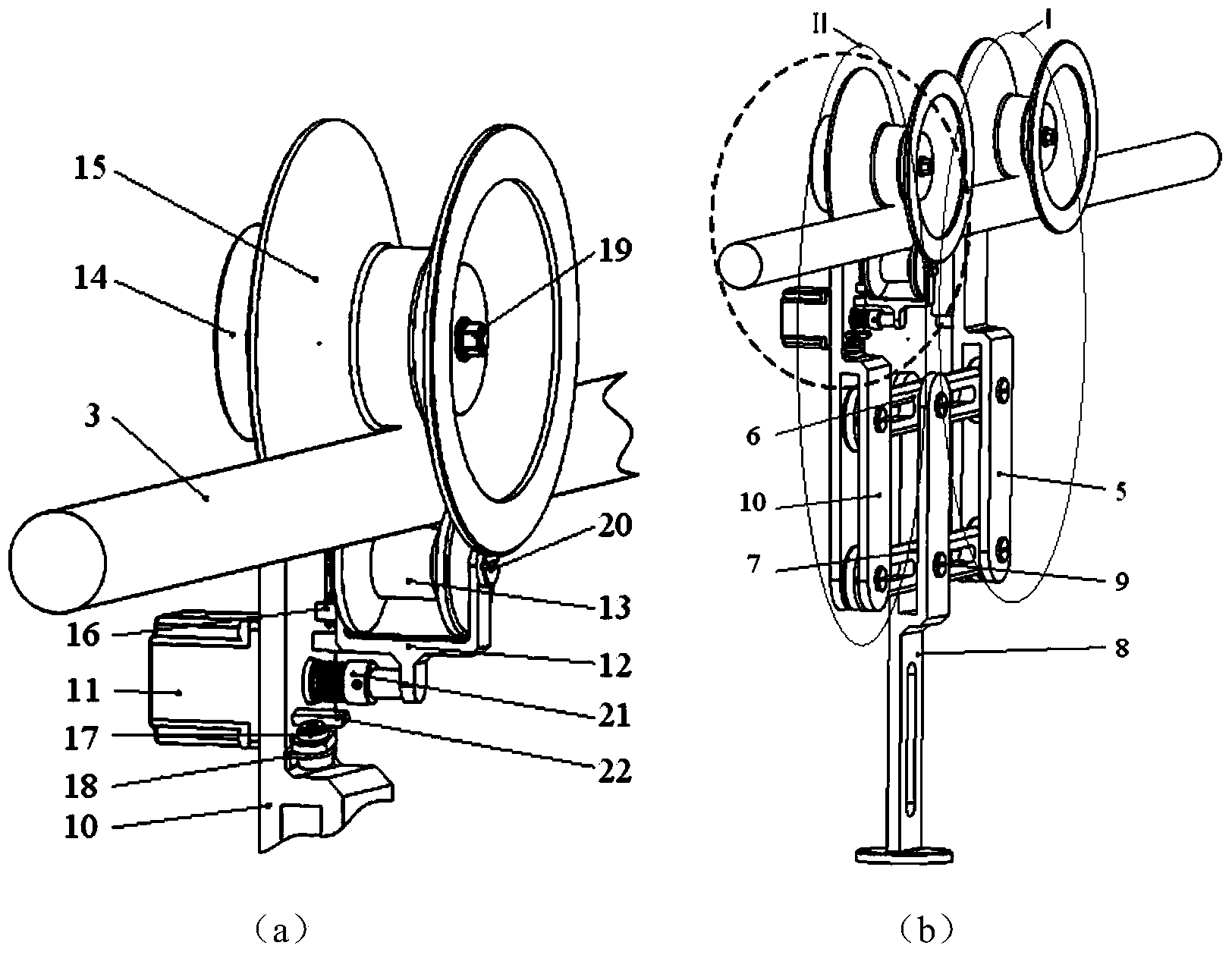

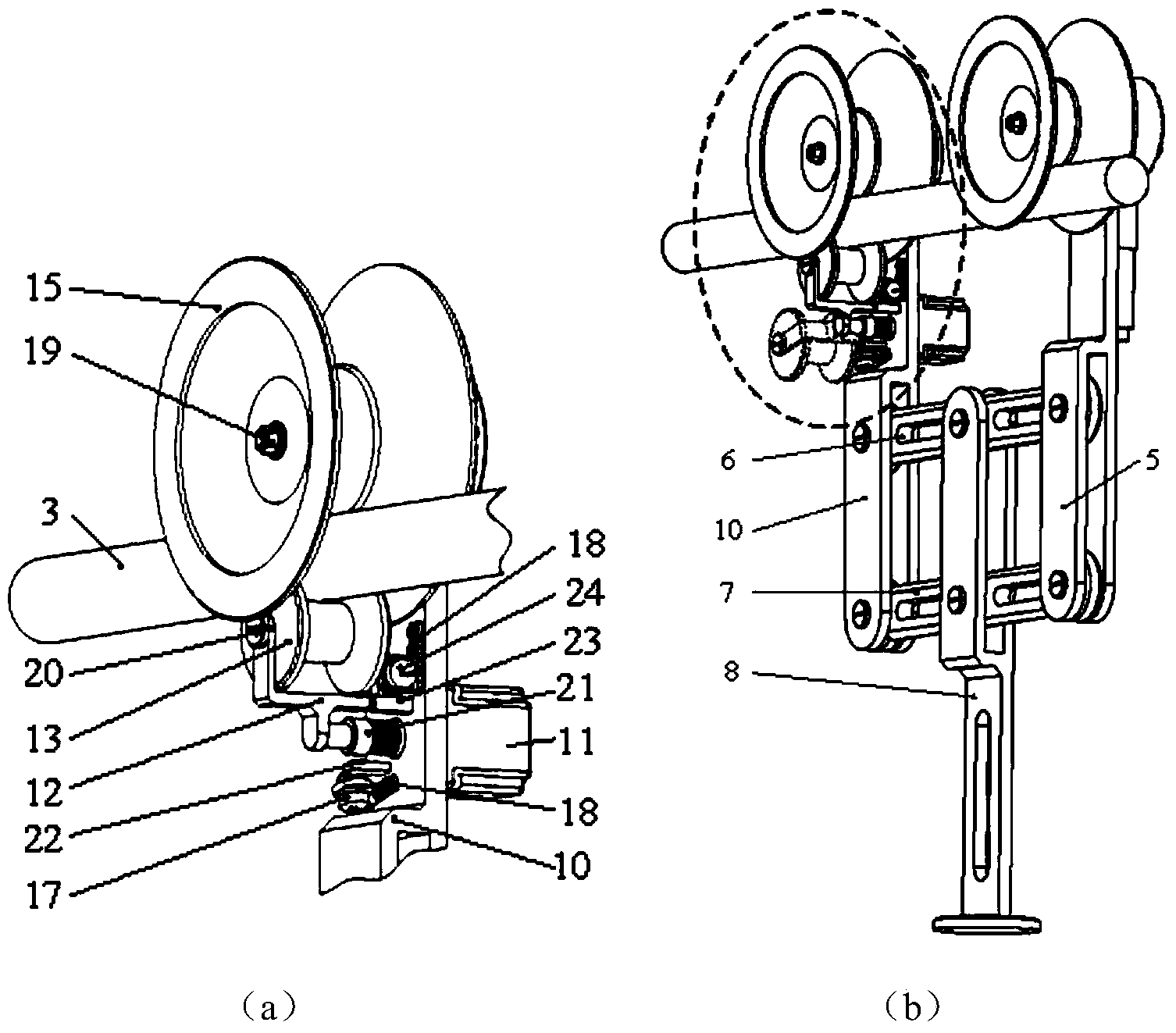

[0022] Implementation Case 1: Combining Figure 1~6 , a walking obstacle-surpassing mechanical arm suitable for a power transmission line inspection robot, including a wheel set mechanical arm, a clamping mechanism and a support arm 8 for walking on a power transmission line; the wheel set mechanical arm includes a walking mechanism I and a walking mechanism II, the traveling mechanism I and the traveling mechanism II use the pin shaft 9 to connect the two identical first connecting rods 6 and the second connecting rods 7 to form a parallelogram structure; the traveling mechanism I includes the traveling arm 5, the traveling wheel 1, the traveling motor 4 and the Reduction box 2, walking mechanism II include auxiliary walking arm 10, auxiliary walking wheel 15, auxiliary wheel shaft 14, bolt 19, the cross-sectional shape of walking arm, auxiliary wal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com