Permanent magnet synchronous motor device with closed self-circulation cooling system for stator

A permanent magnet synchronous motor and cooling system technology, which is applied in the electrical field, can solve the problems of surface temperature rise and uneven temperature distribution of the solid rotor of permanent magnet motors, and achieve good cooling effect, weaken the influence, and reduce the effect of working temperature rise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

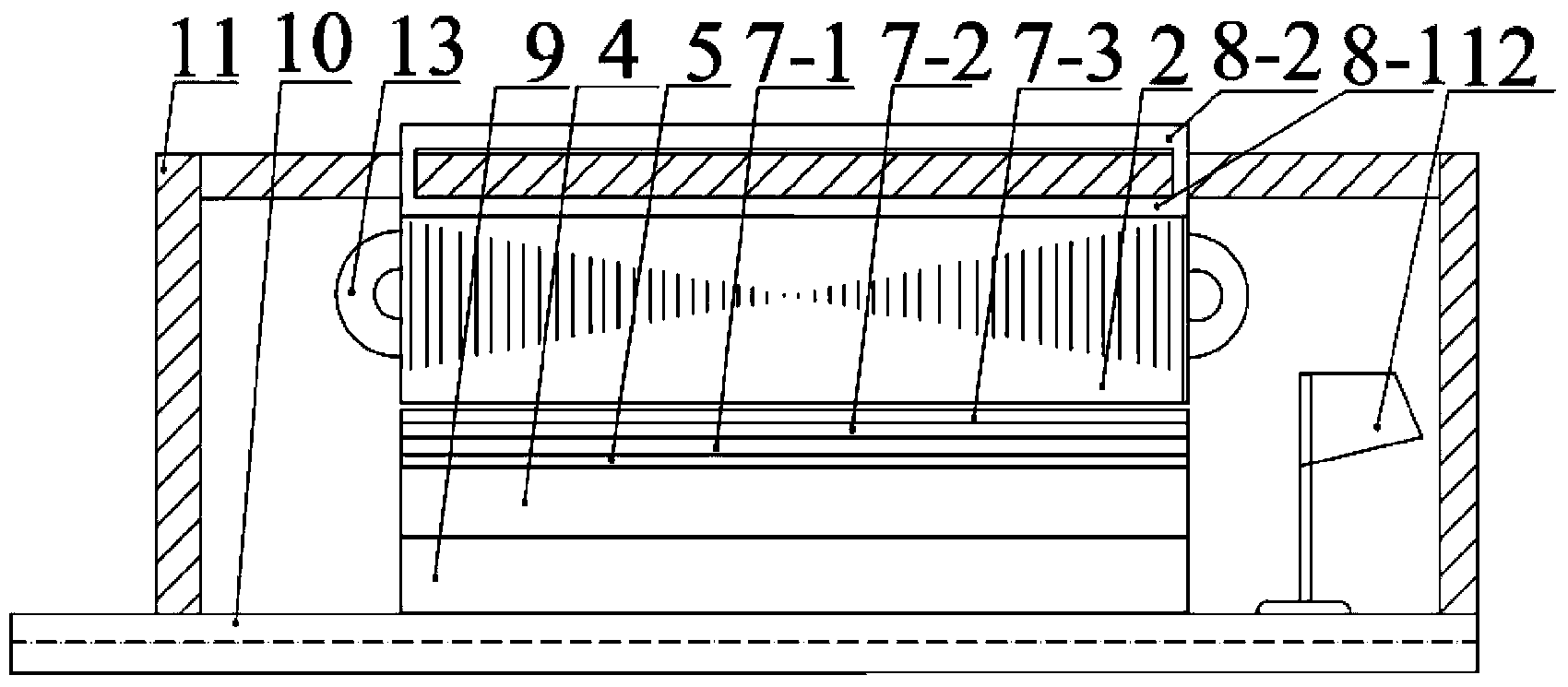

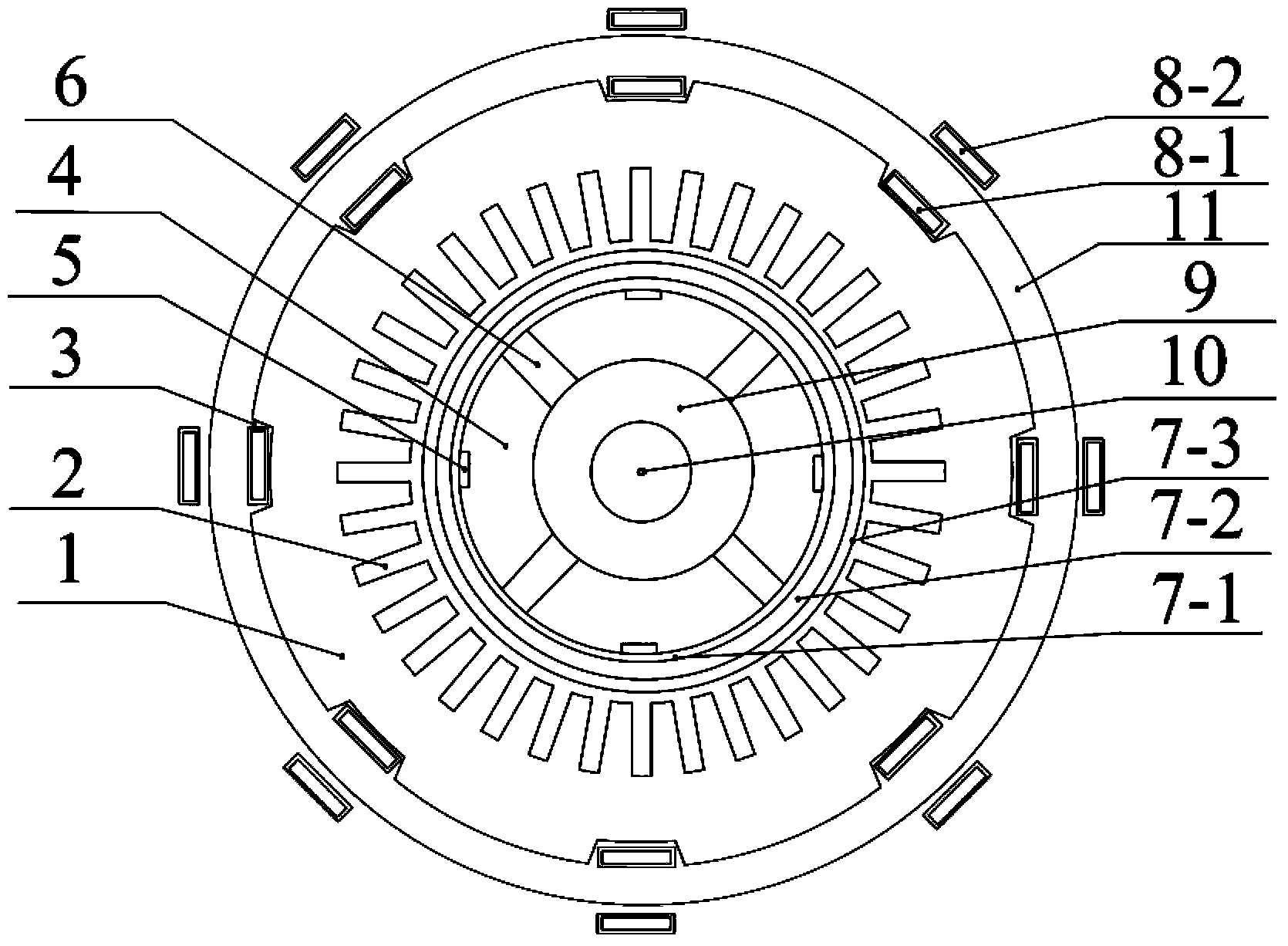

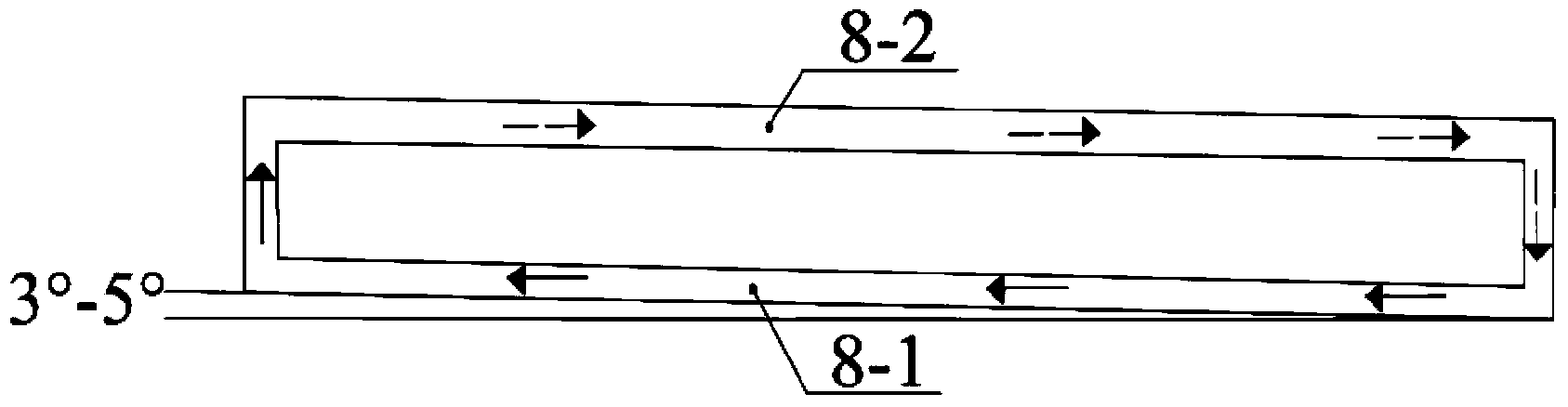

[0017] Embodiment 1: as figure 1 and figure 2 As shown, stator winding slots 2 are evenly distributed along the circumference on the inner side of the stator core 1, and stator ventilation grooves 3 are evenly distributed along the circumference on the outer side of the stator core 1; the number of stator ventilation grooves is 8; the permanent magnet 6 adopts 4 poles , embedded in the rotor core 4 or surface-attached on the rotor core 4; the magnetic isolation ring 9 is keyed to the motor shaft 10; the number of rotor ventilation grooves 5 is 4; the cooling pipe 8 is along the shaft The angle of inclination is 3°-5°. The fan exchanges heat with the cooling liquid in the cooling pipe in the casing, the cooling liquid in the cooling pipe is heated, and after evaporation, the cooling liquid flows to the cooling pipe outside the casing, such as image 3 Indicated by the solid arrow. The cooling pipe outside the casing communicates with the inside and is opposite to the flow d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com