Artificial limb knee joint of gear five-bar mechanism

A knee joint and link mechanism technology, applied in the field of prosthetic knee joints, can solve problems such as the inability to adjust the patient's gait, the inability to freely adjust the parameters of the knee joint, and the inability to fully achieve the kinematic performance of the human knee joint.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] This embodiment is a prosthetic knee joint of a gear five-bar mechanism.

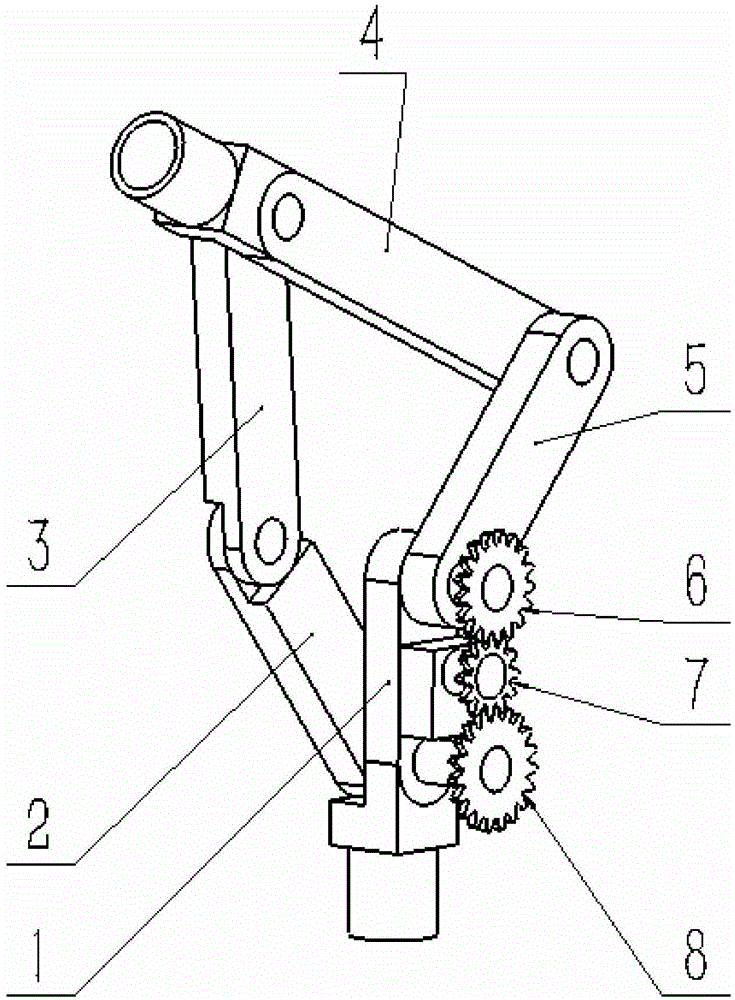

[0015] refer to figure 1 , the prosthetic knee joint of the gear five-bar mechanism in this embodiment is composed of a link mechanism and a gear mechanism. The link mechanism is connected end to end by five links. side of the rod mechanism.

[0016] The link mechanism includes calf link 1, rear control rod 2, support rod 3, thigh link 4, and front control bar 5. The calf link 1 is used as the frame, and the lower end connection port of the calf link 1 is fixedly connected to the lower leg of the prosthesis. , the connecting port at the upper end of the thigh connecting rod 4 is connected with the connecting device of the thigh socket, and the thigh connecting rod 4 and the calf connecting rod 1 are in the same plane in space. The front control rod 5 is installed on the right side of the shank link 1 and the thigh link 4, the lower end of the front control bar 5 is hinged with the upper end of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com