Real-time temperature control system and method for improving casting quality of aluminum alloy component

A real-time control system and real-time control technology, applied in the direction of casting equipment, manufacturing tools, metal processing equipment, etc., can solve the problems of poor internal quality, poor quality of aluminum alloy castings, etc., to save trial production costs, avoid repeated scrutiny and The effect of testing and guaranteeing the qualified rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The temperature real-time control system is applied to the mold and casting of the automobile automatic transmission valve body. From the mold design to the actual casting production, it completely solves the poor product quality (especially the internal quality) caused by the influence of temperature.

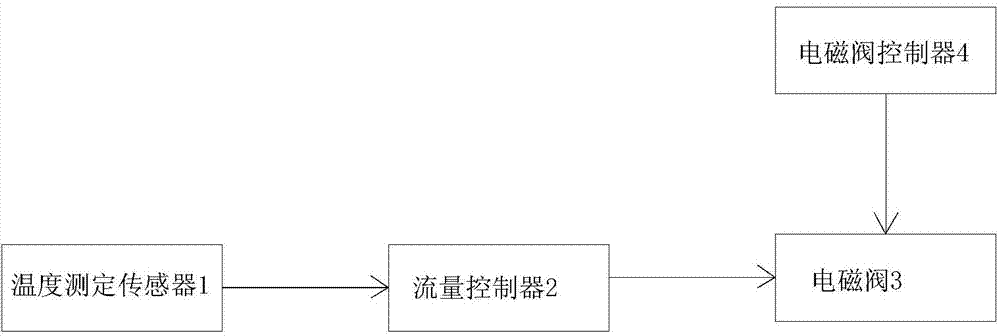

[0029] The temperature real-time control system of the present invention comprises a temperature measuring sensor 1, a flow controller 2, a solenoid valve controller 3 and a solenoid valve 4, the temperature measuring sensor is located in the temperature abnormal area of the mould; the solenoid valve is located in the pipeline of the cooling water pipe; The output end of the temperature measurement sensor is connected to the input end of the flow controller, the output end of the flow controller is connected to the flow control input end of the solenoid valve, and the output end of the solenoid valve controller is connected to the opening and closing signal control end ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com