A sensor for testing internal shear stress of pavement structure layer and its embedding process and application

A pavement structure and sensor technology, which is used in the application of stable shear force to test the strength of materials, preparation of test samples, instruments, etc., can solve the problems of the success rate of sensor damage and burying, inability to obtain, reduce and other problems, so that it is not easy to damage. , Improve the success rate, the effect of precise position relationship

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The technical solution of the present invention will be further described below in conjunction with the accompanying drawings, but it is not limited thereto. Any modification or equivalent replacement of the technical solution of the present invention without departing from the spirit and scope of the technical solution of the present invention should be covered by the present invention. within the scope of protection.

[0022] 1. The layout method of the sensor for measuring the internal shear stress of the asphalt pavement layer

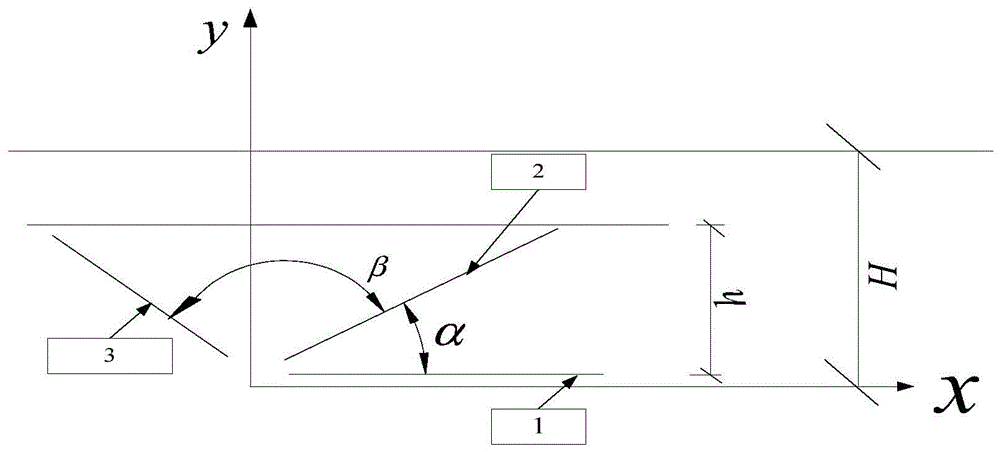

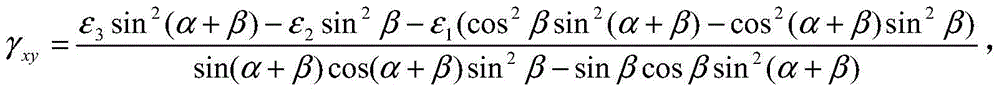

[0023] In order to measure the shear stress in the pavement structure layer, the internal stress field of the pavement can be simplified to a plane stress state. At this time, three strain sensors can be buried in the same plane, and the arrangement is as follows: figure 1 shown. Among them: the first sensor 1 is horizontal, the angles between the first sensor 1, the second sensor 2, and the third sensor 3 are α, β respectively, and the si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com