Cooling system of wind cooling diesel engine

A cooling system and cooling device technology, which is applied in the field of cooling devices and lubricating oil storage parts, can solve the problems of large volume, affecting the overall layout of the engine, complex structure, etc., to achieve improved cooling effect, simple structure, and faster cooling speed Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0008] An example of the implementation of the present invention will be further described below in conjunction with the accompanying drawings.

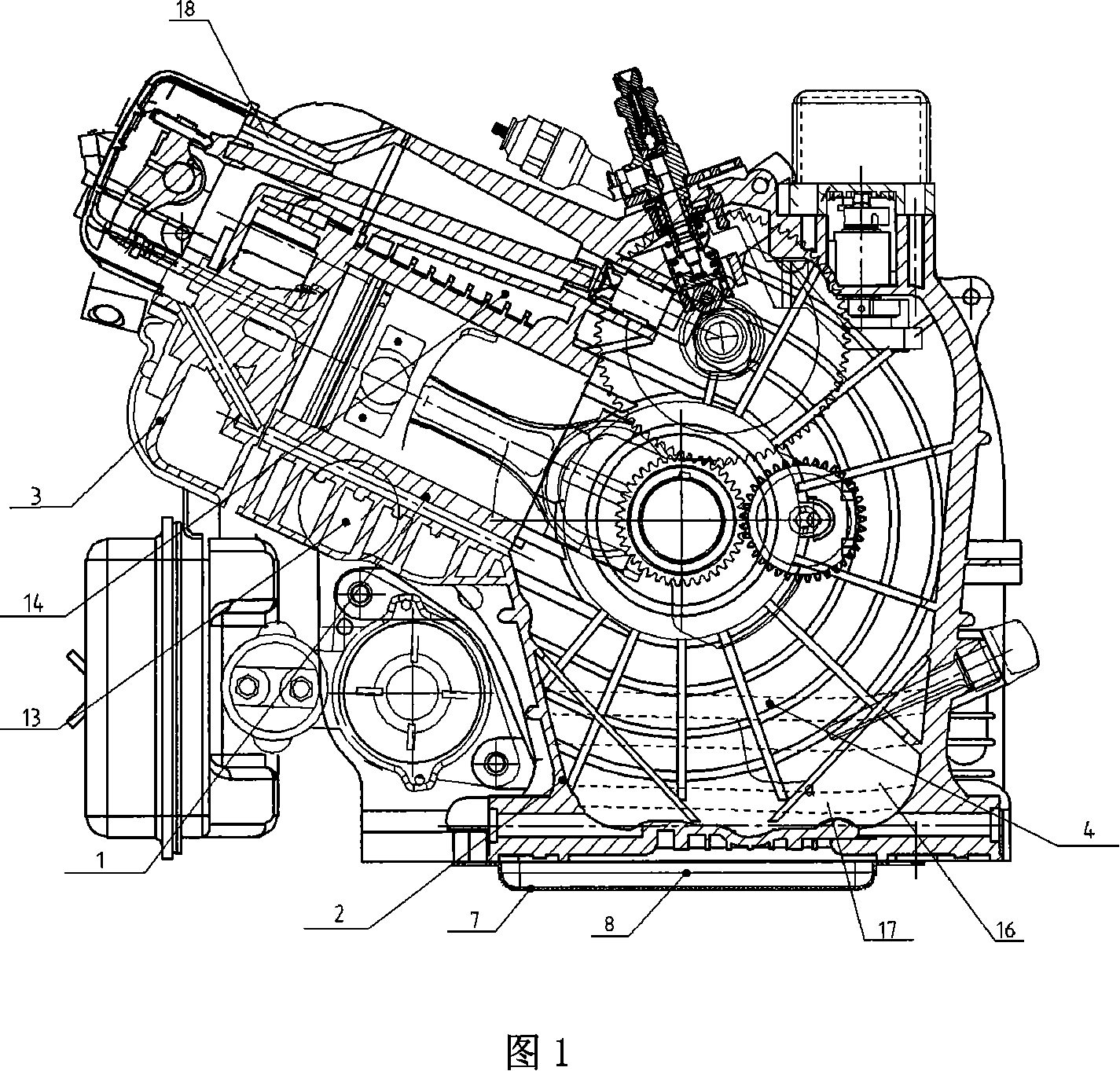

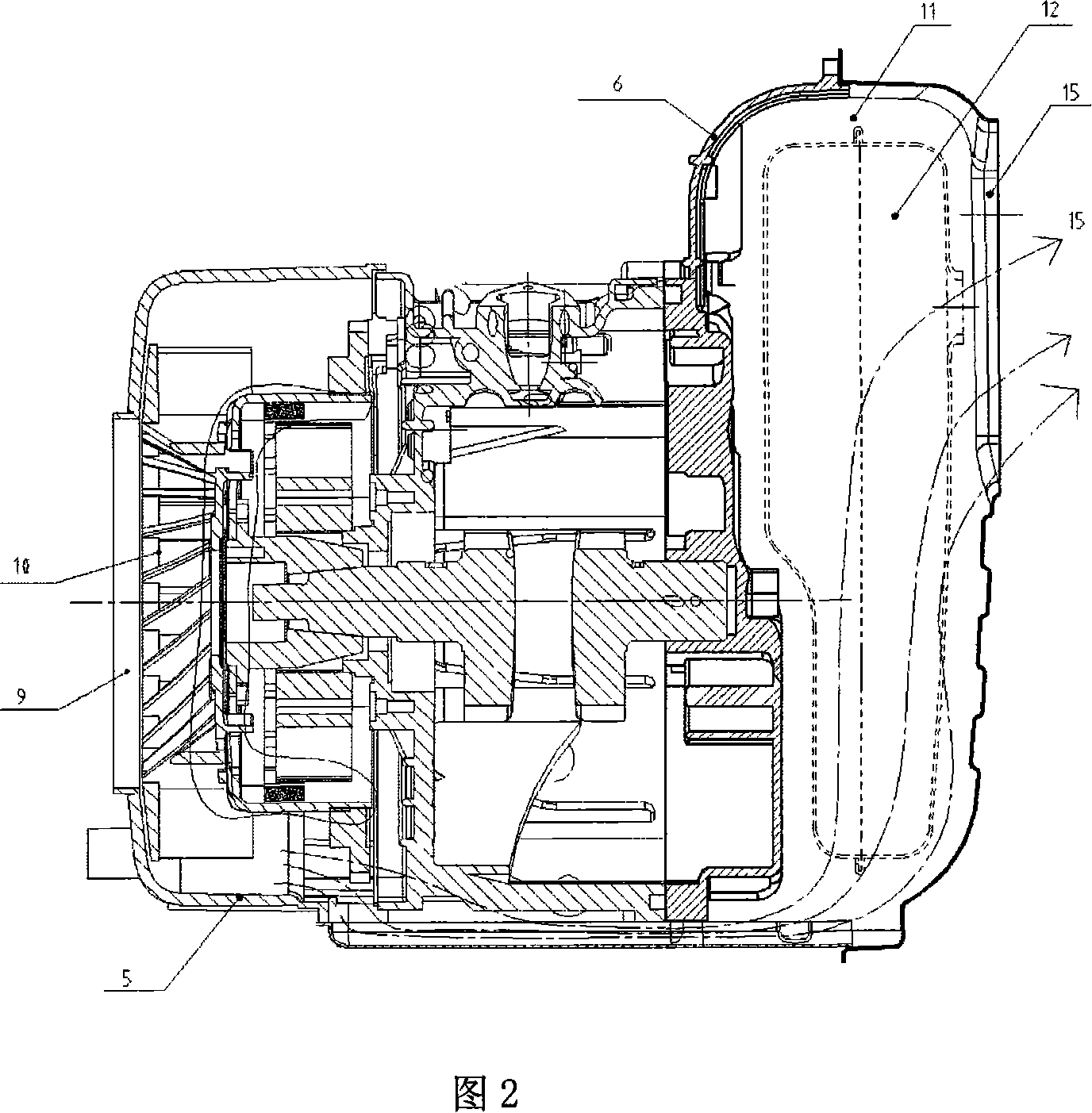

[0009] A cooling device for lubricating oil of an inclined-cylinder engine, comprising a body 2, a cylinder head 3, a crankcase end cover 6, a lubrication system 4, and an air guide system 5, the bottom of the body 2 is provided with a closed cooling system, and the closed The cooling system is a cooling air channel 8 formed between the wind cover 7 and the bottom of the body 2.

[0010] As shown in the figure, when the diesel engine is working, the cooling air enters from the inlet 9 of the wind guide cover, is pressurized by the wind impeller 10, and then the cooling air is transported through the volute channel. There are two main outlets on the conveying channel, one way (the terminal part of the volute channel, where the air pressure is the highest) leads the cooling air to the cooling air ducts 13, 14 and the cylinder head air ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com