Cooling control device for electric vehicles

A cooling control technology for electric vehicles, applied to control devices, electric power devices, battery/fuel cell control devices, etc., can solve problems such as lengthy work, limited driving conditions of electric water pumps, and inability to discharge air bubbles to degassing tanks, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Embodiments of the present invention are described below with reference to the drawings.

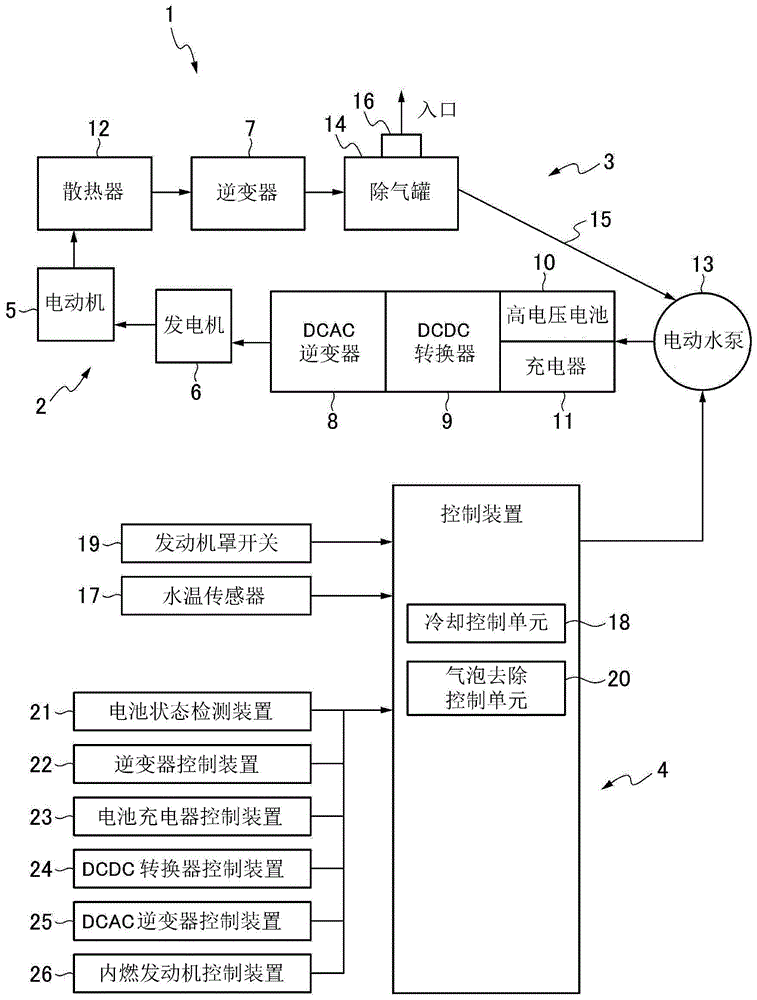

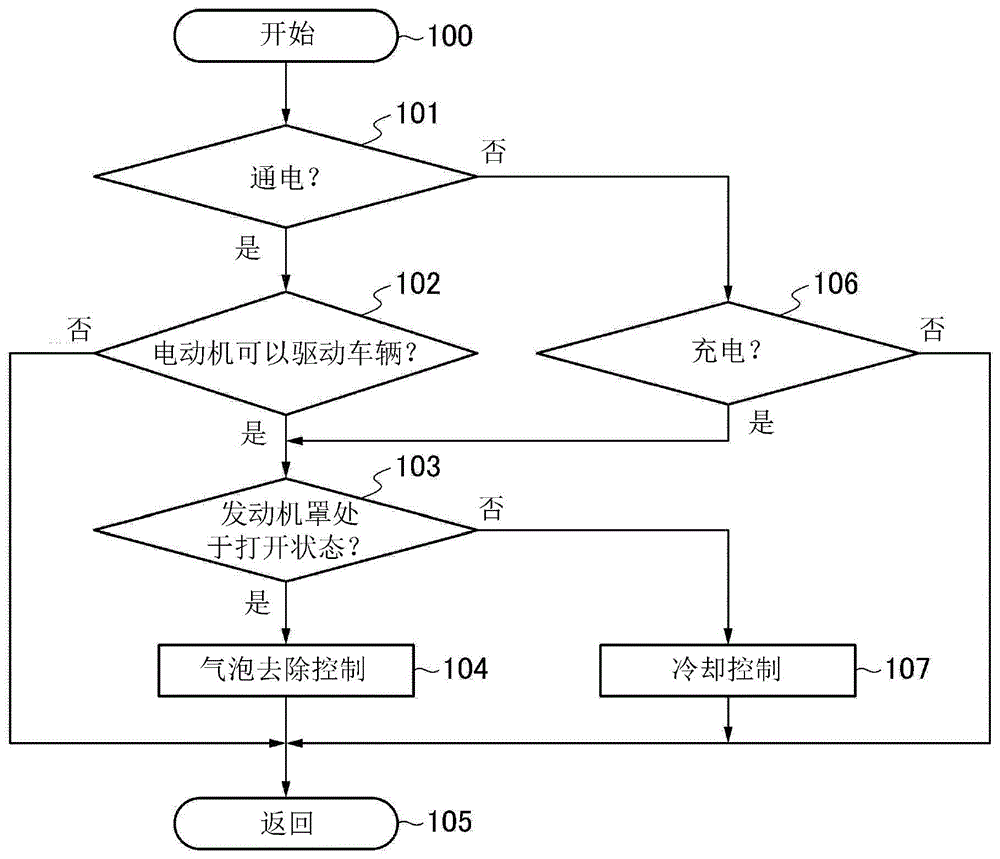

[0019] figure 1 and figure 2 Examples of the present invention are shown. exist figure 1 Among them, a cooling control device 1 for an electric vehicle is provided with a traveling device 2 , a cooling device 3 and a control device 4 .

[0020] The running device 2 includes: an electric motor 5 for outputting driving force to drive the electric vehicle; and high voltage devices such as an engine 6, an inverter 7 for controlling the electric motor 5, a DCAC inverter for outputting AC100V from an accessory outlet 8, a DCDC converter 9 for providing DC12V, a high voltage battery 10 and a charger 11 for charging the high voltage battery 10.

[0021] The cooling device 3 includes: a radiator 12 for radiating heat; an electric water pump 13 for circulating cooling water; a degassing tank 14 for exhausting air; and a cooling water channel 15 for circulating cooling water. The cooli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com