Air noise reducing structure of front pillar

A front pillar, pillar technology, applied in the superstructure, superstructure sub-assemblies, windows and other directions to achieve the effect of reducing wind friction sound

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Hereinafter, embodiments of the present invention will be described in detail with reference to the drawings.

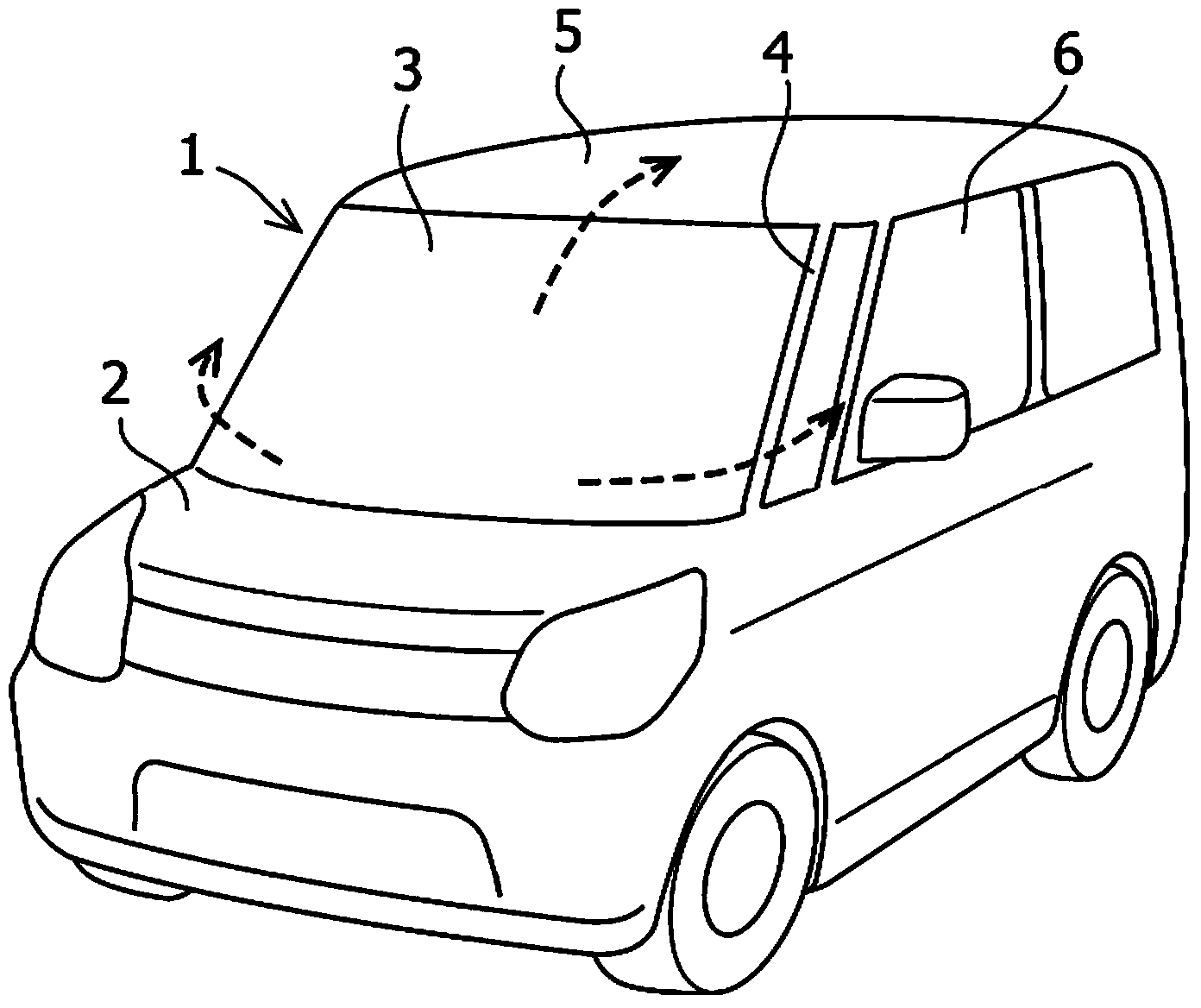

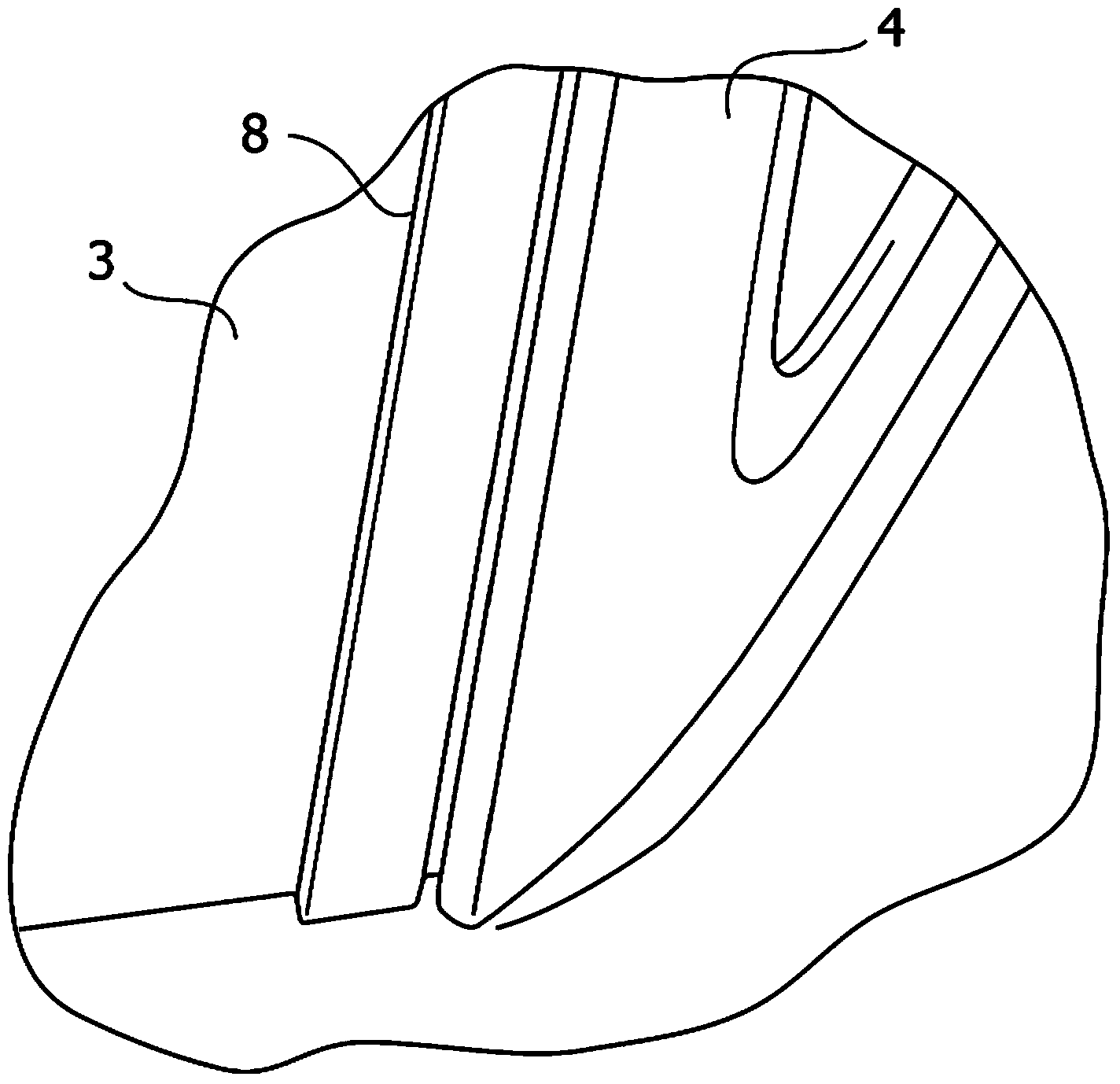

[0028] figure 1 It shows a typical vehicle 1 implementing the air noise reduction structure of the present invention. The vehicle 1 is a small car with a hood 2 (hood) at the front, and includes a windshield with a large rising angle in order to secure a space for the passenger compartment. Glass 3 and front pillar 4.

[0029] In such a vehicle 1, the airflow received from the front by the windshield 3 when the vehicle is running is guided by the inclination of the windshield 3 to the roof 5 side, or guided by the curvature of the windshield 3 to the vehicle body. As shown in the example of the figure, when the front pillar 4 and the windshield 3 are upright, the air flow tends to detour from the front pillar 4 to the vehicle body side 6 significantly.

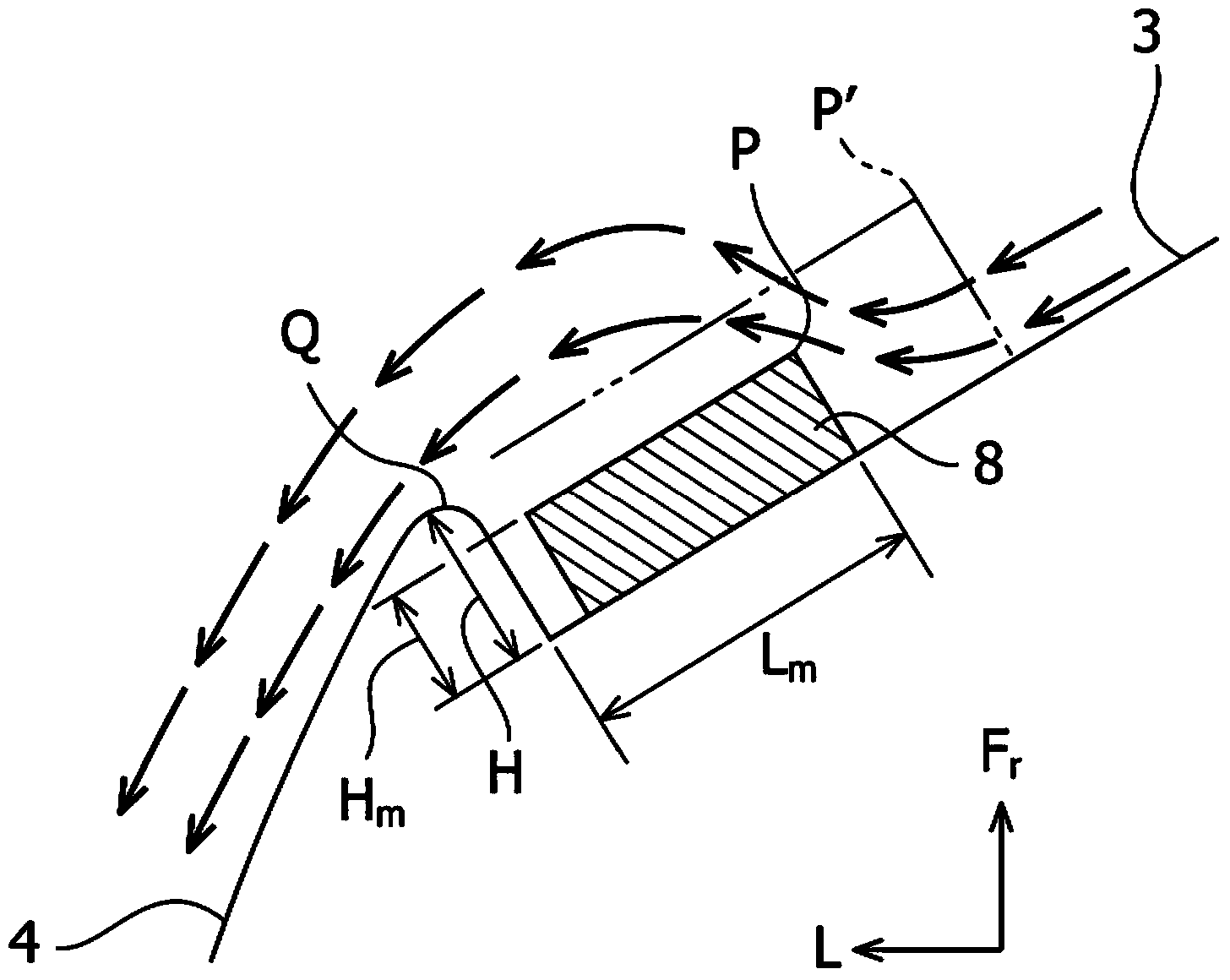

[0030] At this time, near the front pillar 4, such as Figure 4 As shown, the air flow flowing along th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com