Silencing tire cover for carriage noise avoidance

A sound-absorbing, carriage-carrying technology that is applied to vehicle components, superstructures, and sub-assemblies of the superstructure. It can solve the problems of tire noise without a separate noise-cancelling design, and achieve the effects of reducing noise, improving user experience, and reducing noise pollution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described in detail below with reference to the embodiments and accompanying drawings, but the embodiments of the present invention are not limited thereto.

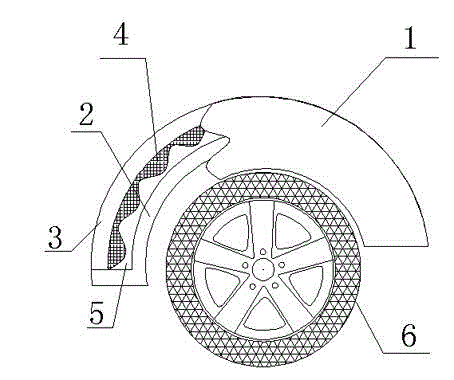

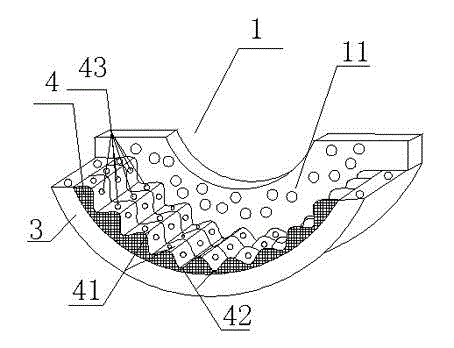

[0019] Such as figure 1 Shown is a cross-sectional view of the noise-absorbing tire cover for the wave car of the present invention, including the baffle plate 3 and the fender 5 installed on the baffle plate, and also includes the Noise-absorbing layer 4, the sound-absorbing layer is located inside the stop plate, and the contour wall of the sound-absorbing layer is wavy. The curved surface of the arc surface presents alternately arranged crests 41 and troughs 42. The contour wall of the sound-absorbing layer is made of metal, usually aluminum or carbon steel. The surface of the contour wall of the sound-absorbing layer is roughened, and the surface roughness is greater than 80um. The distance between the crests 41 is in the range of 2cm-18cm, the height difference between t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Surface roughness | aaaaa | aaaaa |

| Wall thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com