Laser cutting flexible manufacture system

A flexible manufacturing system and laser cutting technology, used in manufacturing tools, laser welding equipment, conveyors, etc., can solve the problems of insignificant improvement in efficiency, poor production efficiency, low production efficiency, and low degree of automation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

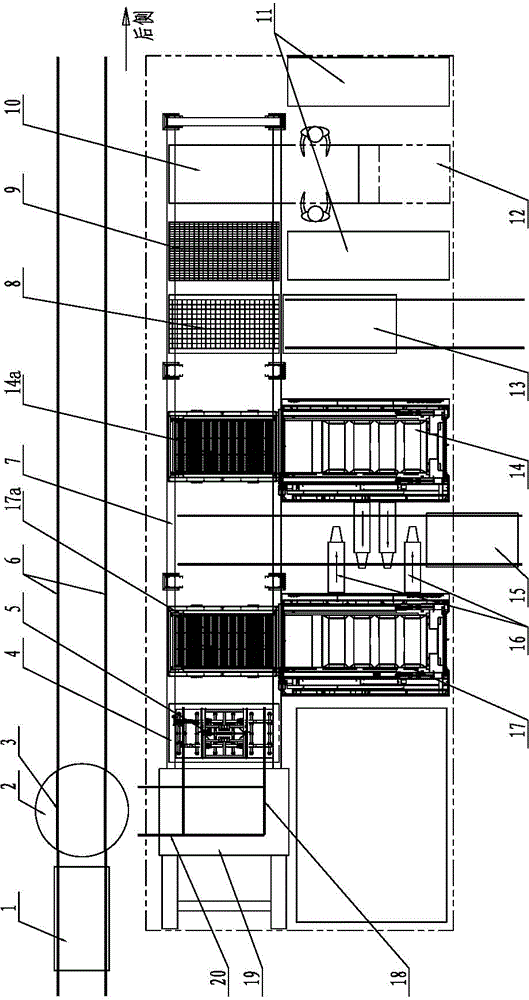

[0015] Such as figure 1 As shown, it is a laser cutting flexible manufacturing system, which includes two laser cutting machines arranged side by side, namely laser cutting machine 1 17 and laser cutting machine 2 14, and the workbench 17a of laser cutting machine 1 and the workbench of laser cutting machine 2 A truss 7 is arranged above 14a, and the front end of the truss 7 is connected with a material warehouse 19, and two feeding guide rails 18 extending into the material warehouse 19 are arranged below the truss 7, and a feeding trolley 4 is arranged on the feeding guide rail 18; There are two storage guide rails 20 extending into the material warehouse 19, and two transfer guide rails 6 are arranged parallel to the truss 7. The transfer vehicle 1 is installed on the transfer guide rails 6, and the storage guide rail 20 and the transfer guide rail 6 are provided with There is a turntable 2, and a turntable guide rail 3 is arranged on the turntable 2. The turntable guide ra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com