Safe lifting clamp

A fixture and safety technology, applied in the direction of transportation and packaging, load hanging components, etc., can solve the problems of random use of hoisting tooling, difficulty in grasping angles and control points, backward methods and use of tooling, etc., to achieve anti-shake positioning High precision, scientific and standardized hoisting operation, and high hoisting efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The successful appearance of the present invention solves the problem of working in the effective space when steel is loaded and unloaded, and it is also applied to the hoisting operation of steel pipes, section steel, and large skid-mounted equipment, and can accurately set the anti-sway point at the designated position of the equipment (steel) , to make it more standardized and efficient, and reduce the safety risk of hoisting. At the same time, this kind of standardized management is very good in our company, and it can be promoted to manufacturing industries such as electric power equipment, metallurgical equipment, oil field equipment, road construction machinery, and construction machinery. It has a large space for promotion and application.

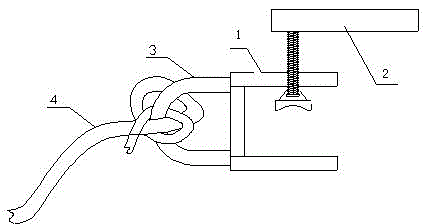

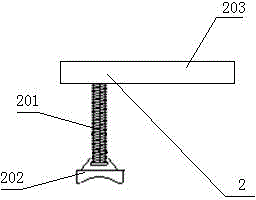

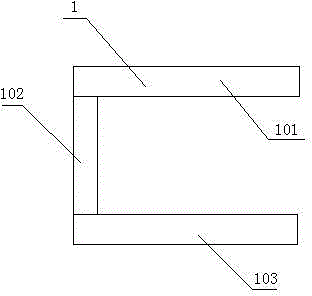

[0020] In order to overcome the problems of low hoisting efficiency, irregular operation behavior and safety risks of current hoisting tools, this embodiment provides such figure 1 , figure 2 and image 3 The safety hoist...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com