Method for continuously synthesizing N-carbamylglutamic acid by using micro-channel reactor

A technology of carbamoylglutamic acid and microchannel reactor, which is applied in chemical instruments and methods, preparation of organic compounds, preparation of urea derivatives, etc., can solve problems such as slow reaction speed, many by-products, complex process, etc. Achieve the effect of rapid reaction, less by-products and less side reactions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~20

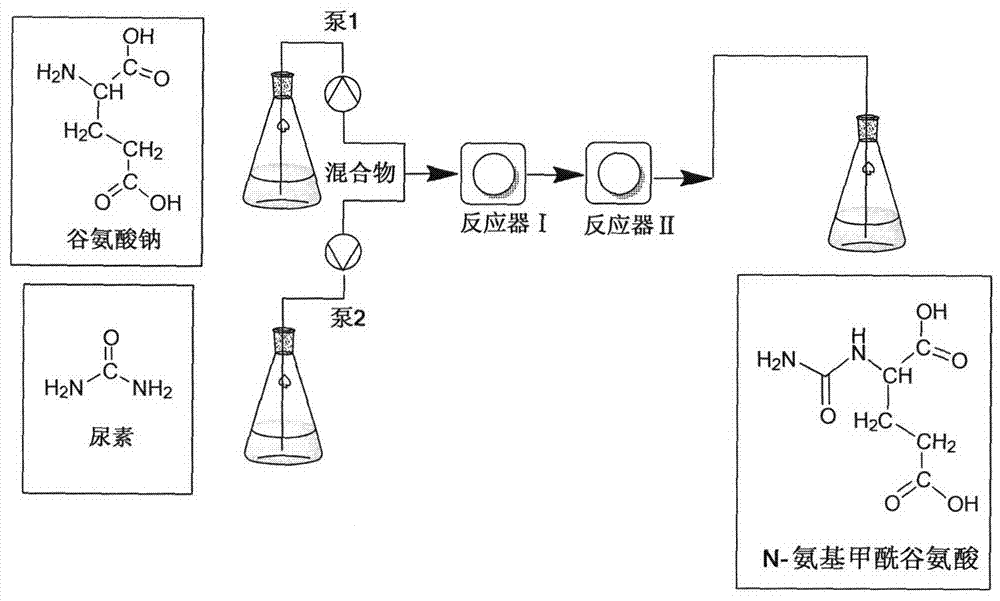

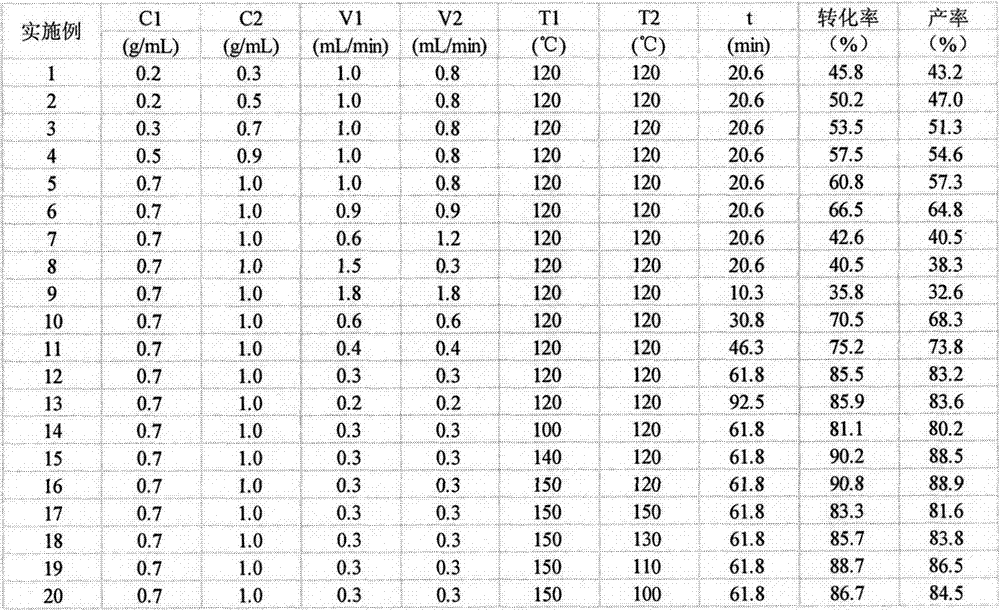

[0027] Prepare sodium glutamate and urea into aqueous solutions, respectively, with concentrations of C1 and C2; pump the sodium glutamate solution and urea solution into the microchannel reactor according to the volume flow ratio V1:V2, and pass through the microchannel reactor in turn. Reactor I and reactor II connected in series, total residence time in reactor I and reactor II is t, and temperature of reaction is T1 and T2 respectively; Recrystallization, etc.) to obtain the finished product of N-carbamylglutamic acid.

[0028] The specific conditions and results of the EHRFELD slit-plate mixer reactor are shown in Table 1. The Vapourtec R4 / R2+ reactor only needs to halve both V1 and V2, and the other conditions are the same as in Table 1. The reaction effect is almost the same as that of the EHRFELD slit-plate mixer reactor.

[0029] Table 1

[0030]

[0031] (1) As can be seen from Examples 1 to 5, when the sodium glutamate solution concentration is 500 to 700g / L, an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com