A bridge deck structure with an ice-melting functional layer and its ice-melting method

A functional layer, ice melting technology, applied in the direction of pavement details, bridges, bridge parts, etc., can solve the problems of corroding bridge deck steel bars, threatening traffic safety, threatening bridge structural safety, etc., to improve effectiveness, reduce thickness, and avoid problems. Corrosion effect of bridge deck reinforcement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] On the cement concrete layer of a highway, the deicing functional layer of the present invention has been implemented. The area of the bridge deck is 220m 2 .

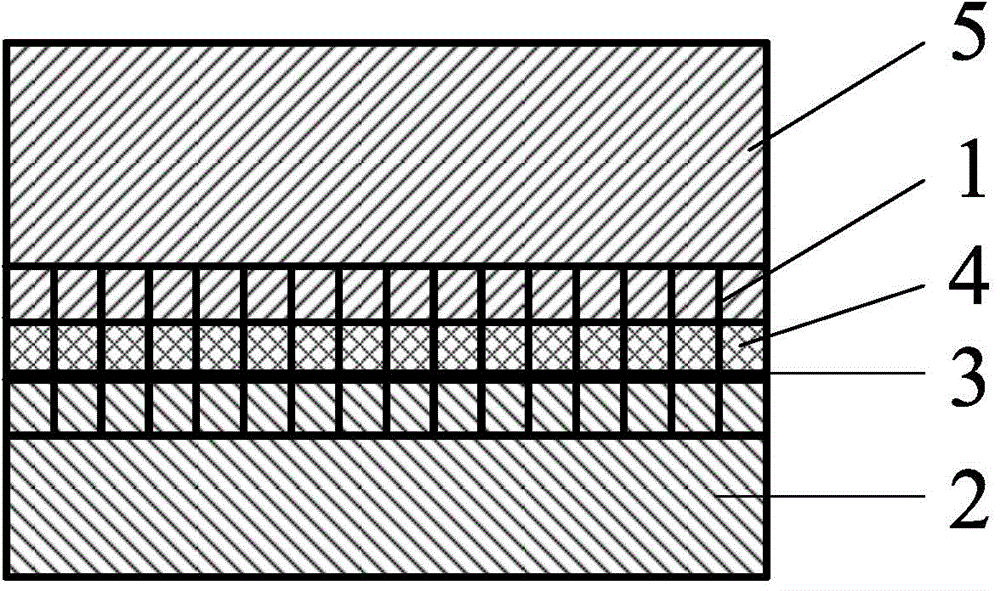

[0034] (1) The structure and materials of the ice-melting functional layer of the bridge deck pavement

[0035] Such as figure 1 As shown, during the construction of the cement concrete layer 2, the steel grid 1 is installed before the initial setting of the cement concrete; after the cement concrete on the bridge deck is cured, the waterproof coating is sprinkled to form the waterproof coating layer 3, wherein the waterproof coating is made of polyurethane material, Spreading amount is 0.1kg / m 2 . After the waterproof coating is cured, a gravel spreader is used to fill the middle layer of the reinforcement grid 1 with conductive aggregate to form the conductive aggregate layer 4 . Finally, the asphalt pavement 5 is constructed so that the upper layer of the reinforcement grid 1 is embedded in the asphalt...

Embodiment 2

[0045] On the cement concrete layer of a municipal road, the deicing functional layer of the present invention is implemented. The bridge deck has an area of 138m 2 .

[0046] (1) The structure and materials of the ice-melting functional layer of the bridge deck pavement

[0047] Such as figure 1 As shown, during the construction of the cement concrete layer 2, the reinforcement grid 1 is installed before the initial setting of the cement concrete; After the waterproof coating is cured, a gravel spreader is used to fill the middle layer of the reinforcement grid 2 with conductive aggregate 4 . Finally, the asphalt pavement 5 is constructed so that the upper layer of the reinforcement grid 1 is embedded in the asphalt pavement.

[0048] Among them, the waterproof coating adopts epoxy resin material. Spreading amount is 1.0kg / m 2 .

[0049] The conductive aggregate is iron ore with an iron content of 10%, and the particle size is 9.5mm-13.2mm.

[0050] Such as figure...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com