Multistage compressor section-by-section pressure control device based on PLC (programmable logic controller)

A pressure control and compressor technology, applied in pump control, mechanical equipment, machine/engine, etc., can solve the problems of harsh working conditions, large pressure drop before and after, and high cost, achieve stable pressure, increase stability and safety, Realize the effect of automatic control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

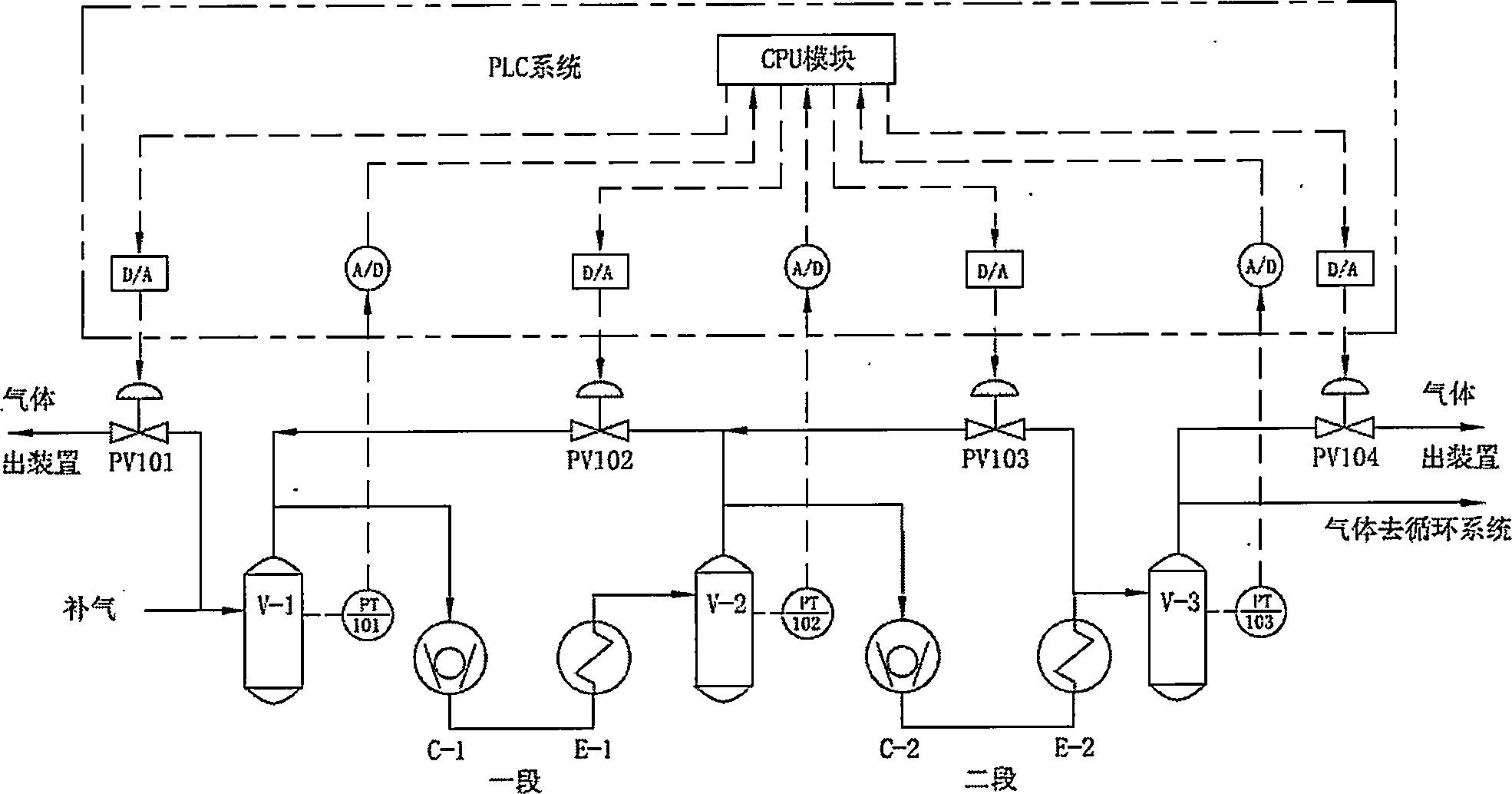

[0017] Convert the output analog signal of pressure transmitter PT101, PT102, PT103 to 0~100% through PLC scale conversion program, and convert the input control analog signal of valve PV101, PV102, PV103, PV104 through PLC scale conversion Program conversion from 0 to 100%.

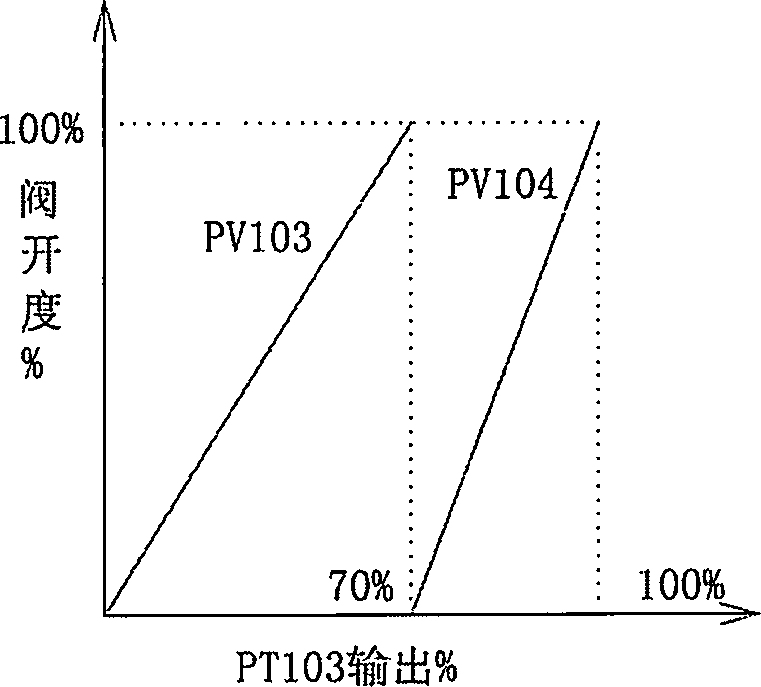

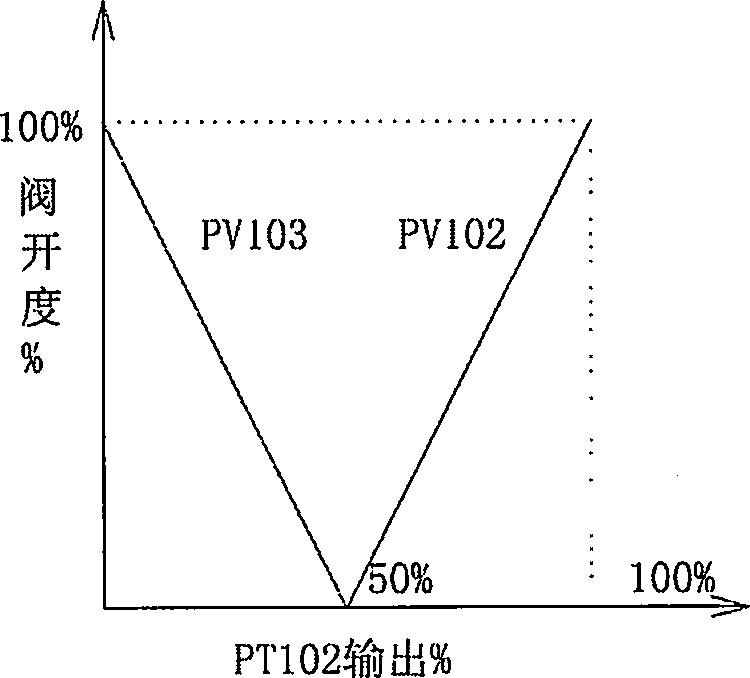

[0018] Such as figure 1 As shown, when the output of the pressure transmitter PT103 of the liquid separation tank V-3 is 0-70%, the PLC program chooses to gradually increase the opening of the valve PV103, that is, to increase the return volume of the liquid separation tank V-3 and reduce the gas in the tank Pressure; when the output of the pressure transmitter PT103 is 70%, the opening of the valve PV103 is 100%, and the valve PV103 is fully opened. When the output of the pressure transmitter PT103 is 70% to 100%, the PLC program chooses to gradually increase the valve PV104 At this time, the excess gas in the liquid separation tank V-3 is discharged from the system to reduce the gas pressure in the ta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com