Large-stroke high-energy-dissipation shape memory alloy buffer

A memory alloy and buffer technology, applied in the direction of low internal friction spring, etc., can solve the problems of limited application scope, complex structure, buffer stroke dependent on the length of alloy wire, etc., to achieve high material utilization, high energy dissipation capacity, Conducive to the effect of buffer protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The specific implementation manners of the present invention will be described in detail below in conjunction with the technical solutions and with reference to the accompanying drawings.

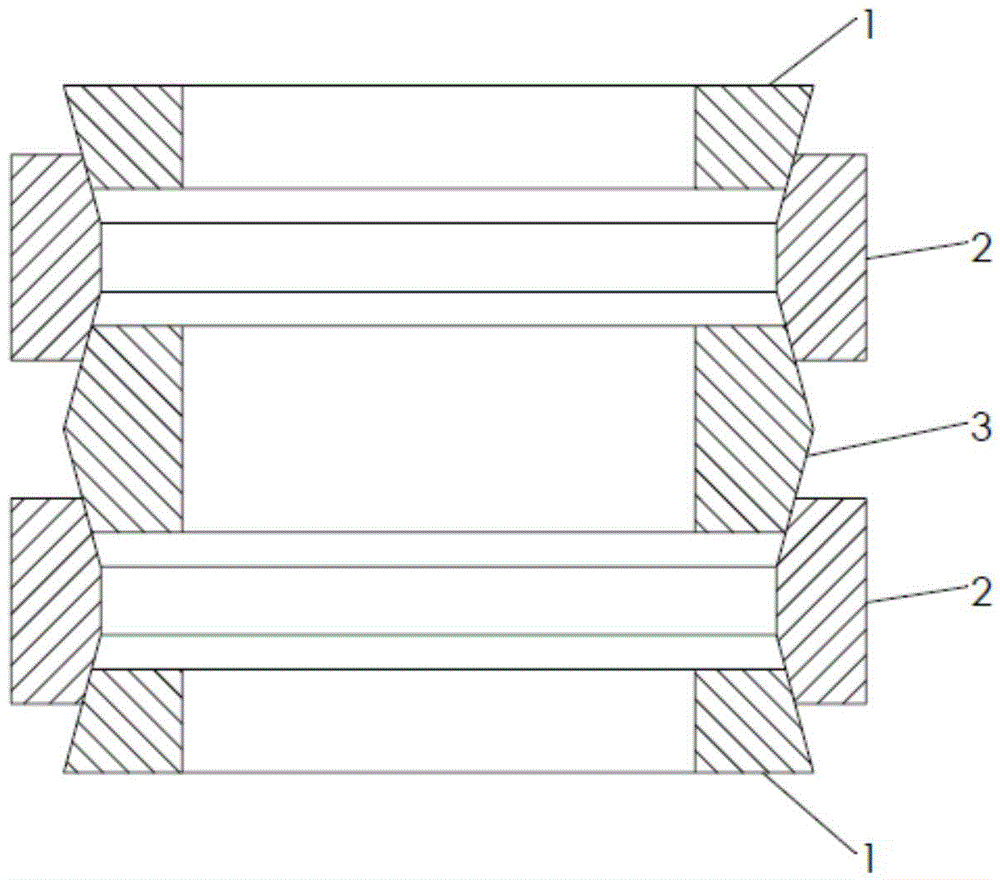

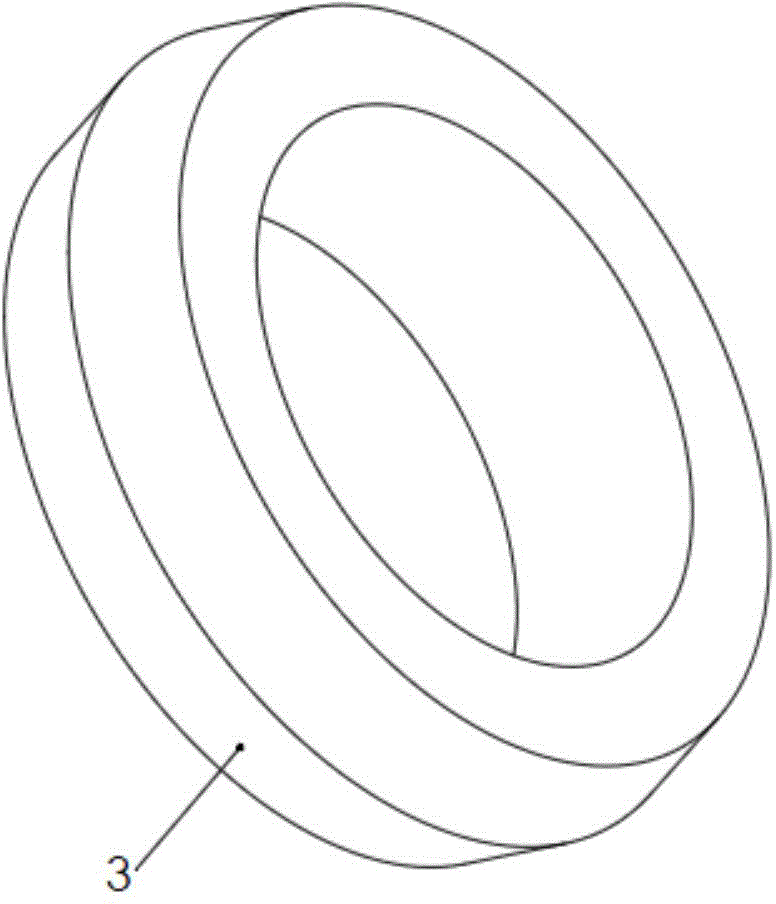

[0029] An embodiment of a basic model of the patent of the present invention, such as figure 1 As shown, it includes three parts: a single-cone inner ring 1, a double-cone inner ring 3, and a shape-memory alloy outer ring 2 with double inner cones. According to the needs of the actual stroke, the logarithm of the inner and outer rings can be selected and assembled by overlapping. The two ends are single-cone inner rings 1, and the middle is several shape-memory alloy outer rings with double inner cones. 2 and double-cone inner rings 3 are alternately arranged.

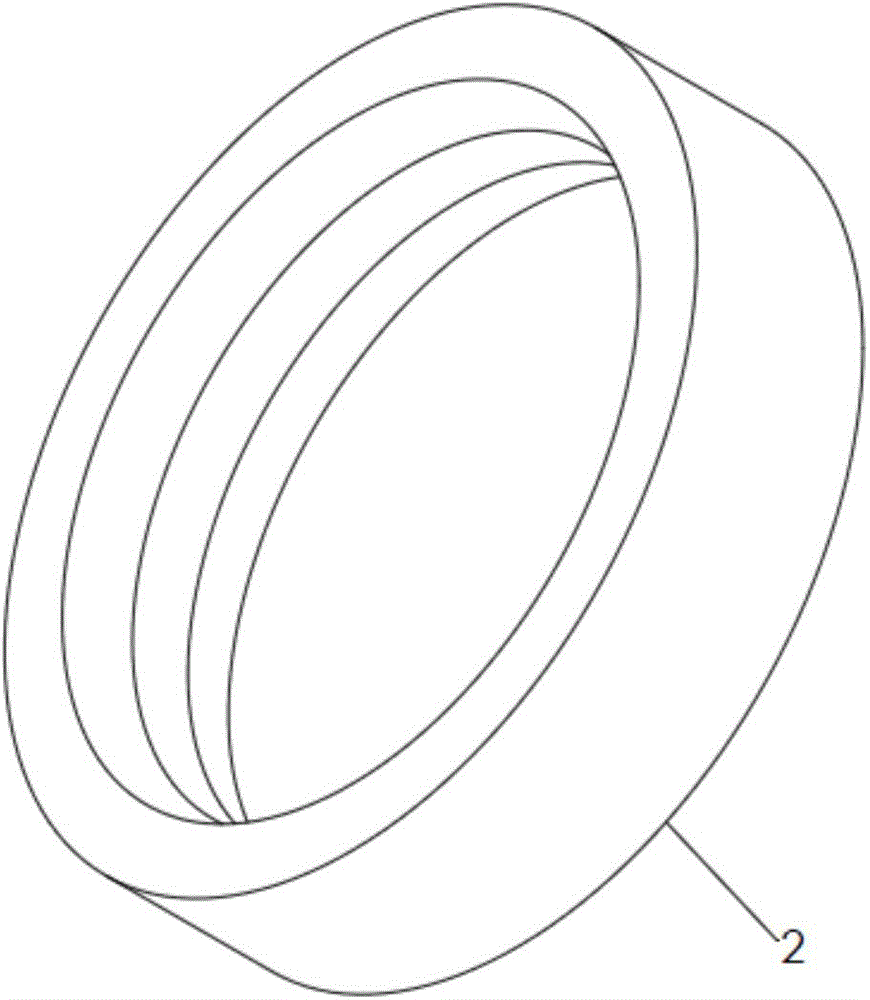

[0030] The taper angles of the inner and outer rings are equal, preferably between 12° and 20°. A shape memory alloy outer ring 2 with double inner cones, its structure is as follows figure 2 As shown, the outer surface i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com