Novel rotary movable sealing element

A technology of dynamic seals and seals, applied in the direction of engine seals, engine components, mechanical equipment, etc., can solve the problems of reducing the service life of O-rings, high cost, complex structure, etc., and reduce frictional resistance and wear. , Reduce interface leakage, simple and reliable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Describe the present invention below in conjunction with specific embodiment:

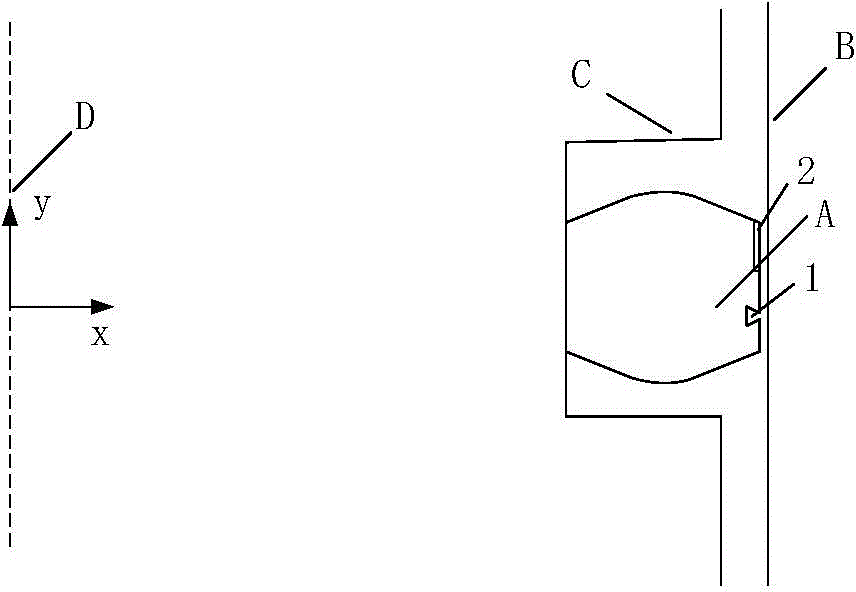

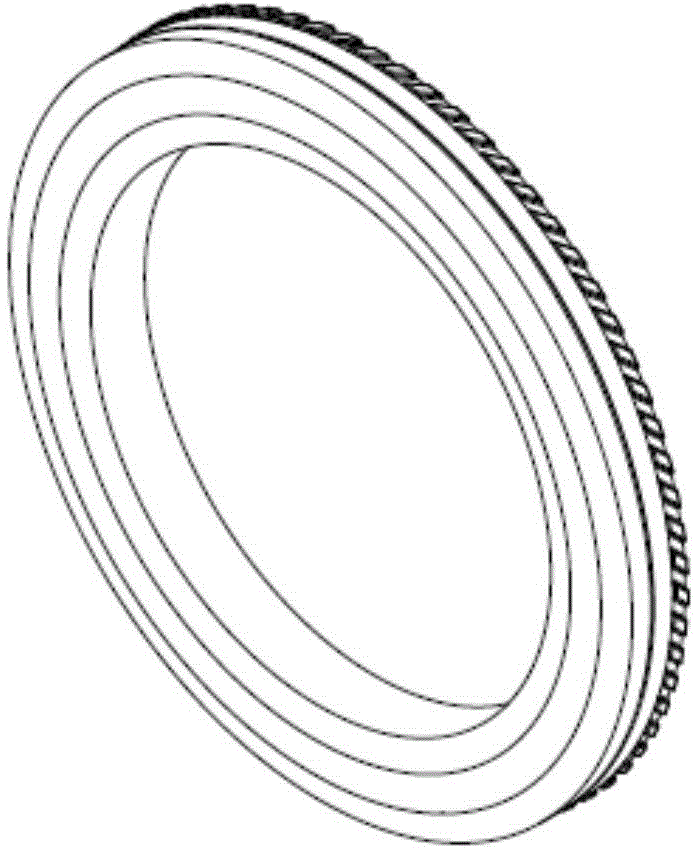

[0016] Refer to the attached figure 1 , the seal in this embodiment is used for the sealing fit of the flange connection. like figure 1 As shown, the seal is a ring-shaped structure, and the direction of the symmetry axis perpendicular to the sealing ring is defined as the x direction, and the direction of the symmetry axis is defined as the y direction.

[0017] The seal in this embodiment is made of rubber, and its cross-sectional shape is as follows figure 1 . The positive and negative directions of the x-axis of the seal are approximate planes, which are used to generate a wider sealing contact surface and obtain better sealing performance; at the same time, it can prevent the seal from turning over and ensure the stability of the seal under working conditions. The positive and negative directions of the y-axis of the seal are outwardly convex arcs, which further ensures the stabilit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com