Lens module assembling process

A lens module and lens technology, applied in the direction of installation, optics, instruments, etc., can solve the problems of non-tight fit design, offset and tilt of the optical axis center, increased equipment cost, etc., to reduce the chance of contamination and reduce the optical axis Center offset, effect of reducing dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

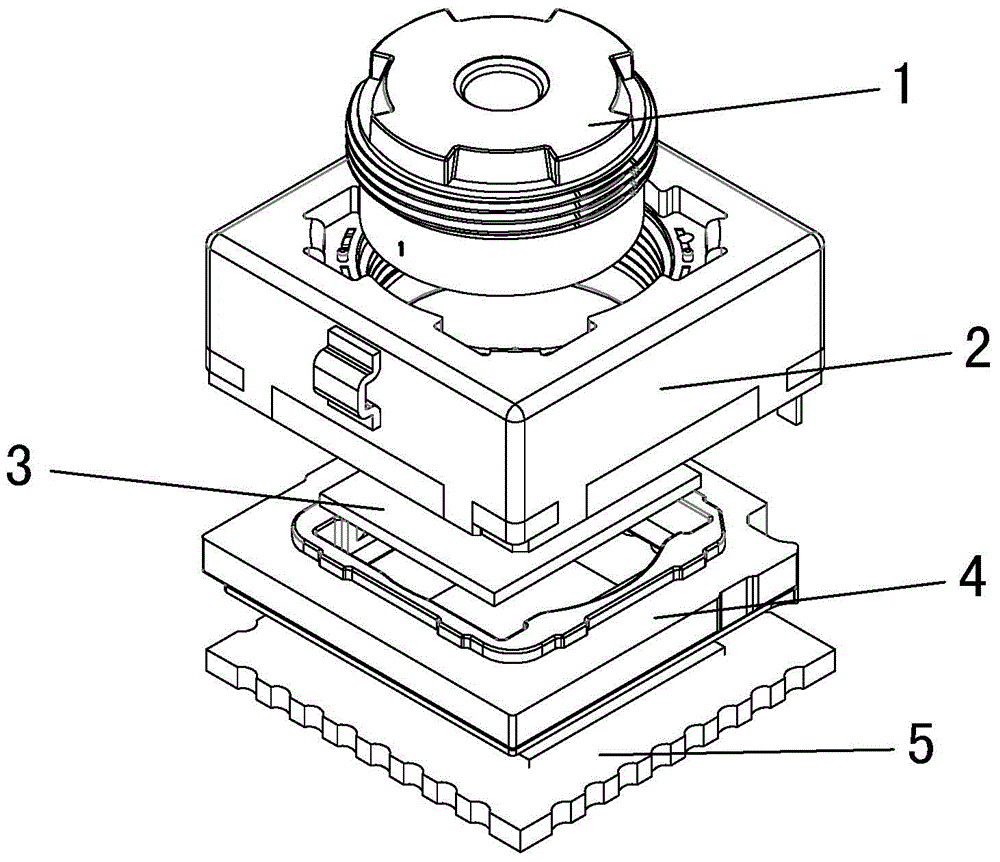

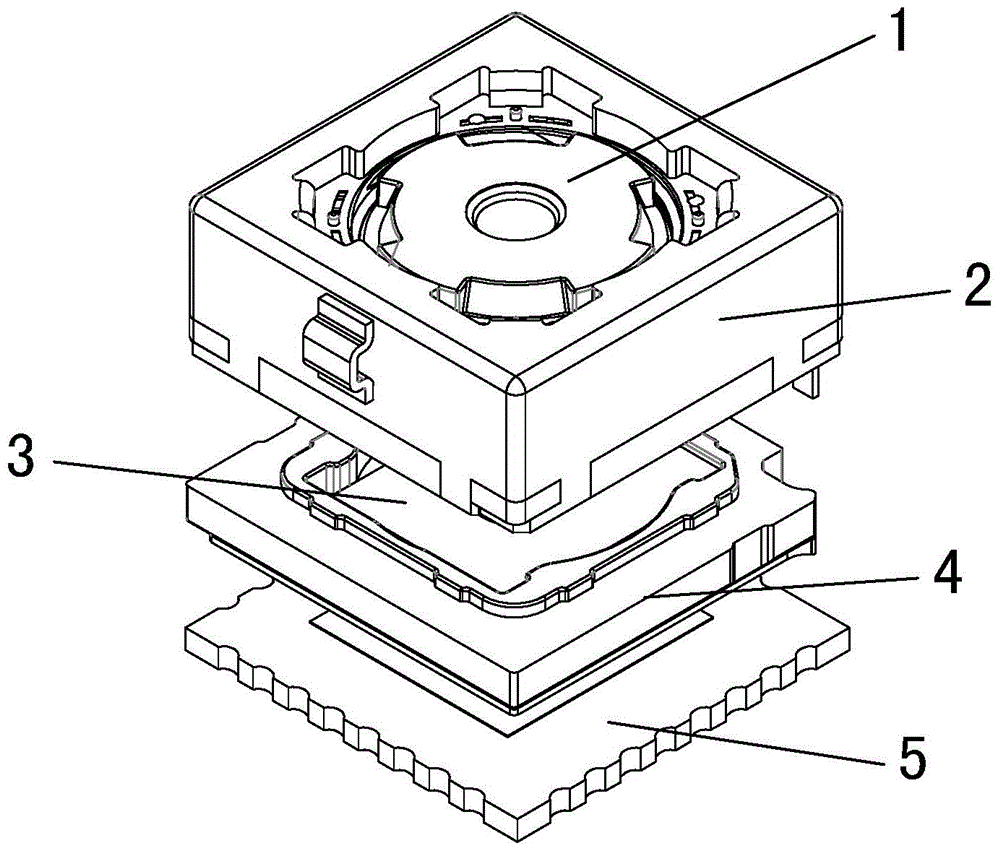

[0032] like figure 1 As shown, a lens module includes a lens 1 (Lens), a voice coil motor 2 (VCM), a filter lens 3 (Glass), a lens holder 4 (Holder), and a printed circuit board 5 (PCB). The lens assembly process requires Assemble these products into a whole.

[0033] like figure 2 As shown, this is the traditional lens module assembly process. First assemble the lens holder 4 (Holder) & filter lens 3 (Glass), attach them to the printed circuit board 5 (PCB), and finally attach the audio Circle motor 2 (VCM) + lens 1 (Lens) assembly.

[0034] The lens 1 module assembly process provided by the present invention includes the following steps:

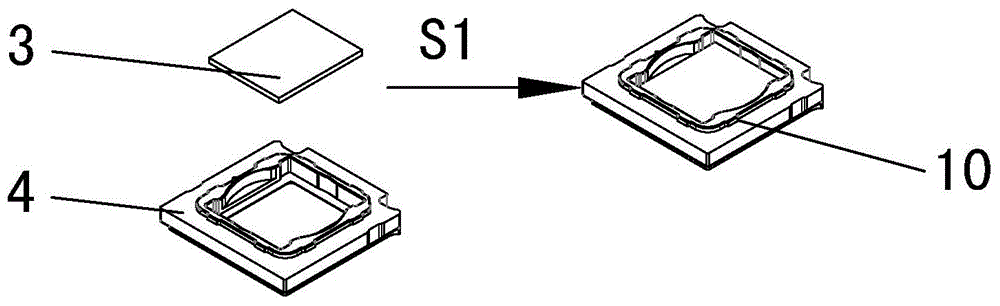

[0035] 1. If image 3 As shown, this is a lens module assembly process step S1 disclosed in the present invention, the lens holder 4 (Holder) + the filter lens 3 (Glass) are assembled into the first assembly 10;

[0036] like Figure 4 As shown, this is a lens 1 module assembly process step S2 disclosed in the present invention, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com