Method for manufacturing brake disc, support bell for brake disc and brake disc

A bell-shaped, brake band technology, applied in the direction of brake components, brake discs, brake types, etc., to solve problems such as increasing storage and transportation volume and weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

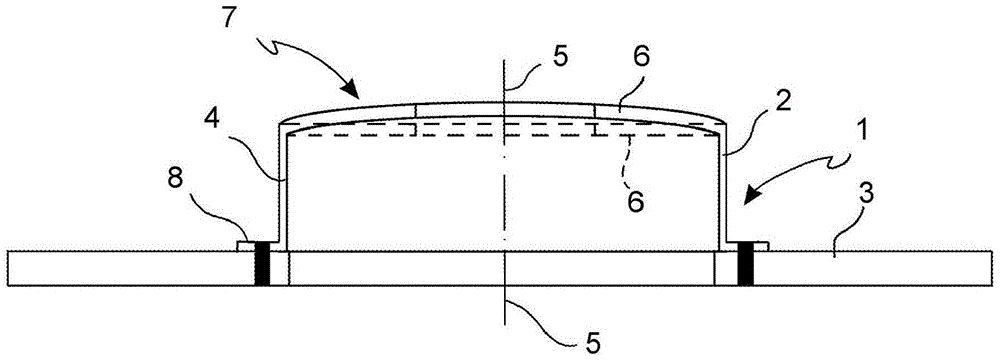

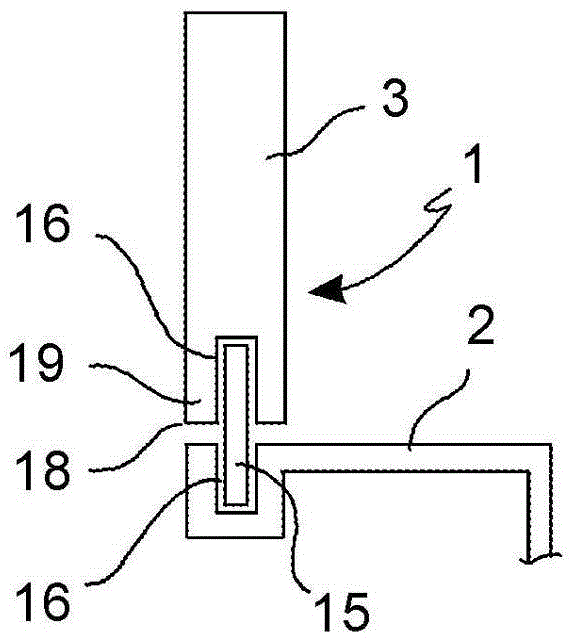

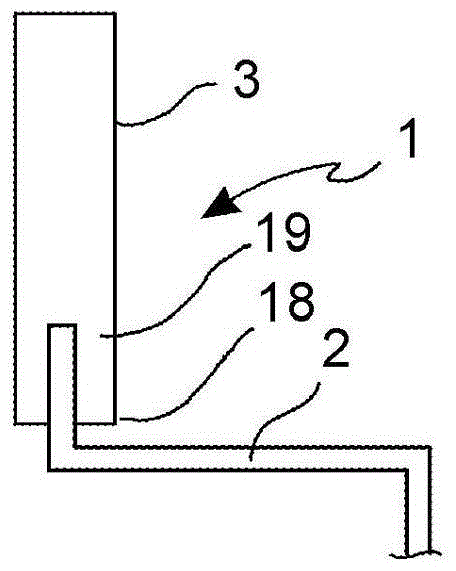

[0046] With reference to the accompanying drawings, a composite brake disc is fully indicated with reference numeral 1 and comprises a bell 2 made of a first material, preferably sheet metal, in particular steel or aluminum alloy, and comprises Brake band 3 made of a second material, eg cast iron, aluminum alloy or fiber reinforced ceramic material.

[0047] The bell 2 has a connection 7 for connecting the brake disc 1 to the hub of the vehicle and a coupling 8 for connecting the bell 2 to the brake band 3 . The connecting portion 7 of the bell 2 is shaped as a cup having a tubular side wall 4 substantially coaxial with the axis of rotation (generally the axis of symmetry) 5 of the brake disc 1 and having transverse to the side wall 4 and preferably The bottom wall 6 is substantially perpendicular to the axis of rotation 5 . A coupling portion 8 is generally formed at the end of the side wall 4 opposite to the bottom wall 6 .

[0048] Brake band 3 ( Figure 3A to Figure 3C ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com