Adjustable resonance block

A resonant block and adjustable technology, applied in the directions of transportation and packaging, vehicle parts, etc., can solve the problems of limited adjustment range, unstable structure, complex structure of assembled resonator block, etc., to reduce development time and cost, and reduce costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The content of the present invention will be described below in conjunction with specific embodiments.

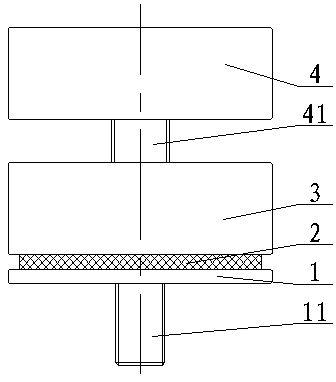

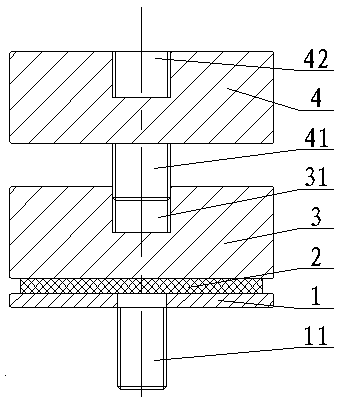

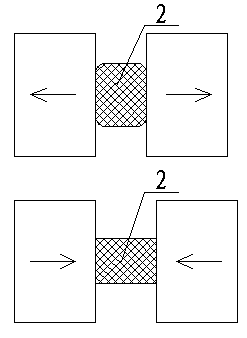

[0025] like figure 1 and figure 2 As shown, it is a structural schematic diagram of an adjustable resonant block according to the present invention. An adjustable resonant block according to the present invention includes: a bottom plate connector 1 for installing the resonant block on an automobile component, the bottom plate connector 1 is in the shape of a round cake, and the bottom surface axis of the bottom plate connector 1 is A first bolt 11 is arranged at the center, and the first bolt 11 is used to connect auto parts; a mass block for adjusting the quality of the resonance block, the mass block itself is adjustable, and the mass block is also a round cake shape; the rubber 2 used to change the stiffness of the resonance block, the rubber 2 is also in the shape of a round cake, the rubber 2 is connected to the top surface of the bottom plate connector 1 t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com