Beer valve

A beer and valve body technology, which is applied in the field of beer valves, can solve the problems of destroying the taste and freshness of draft beer, difficulty in filling the bottle, and a large amount of foam, so as to achieve the effect that the taste and freshness are not affected.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

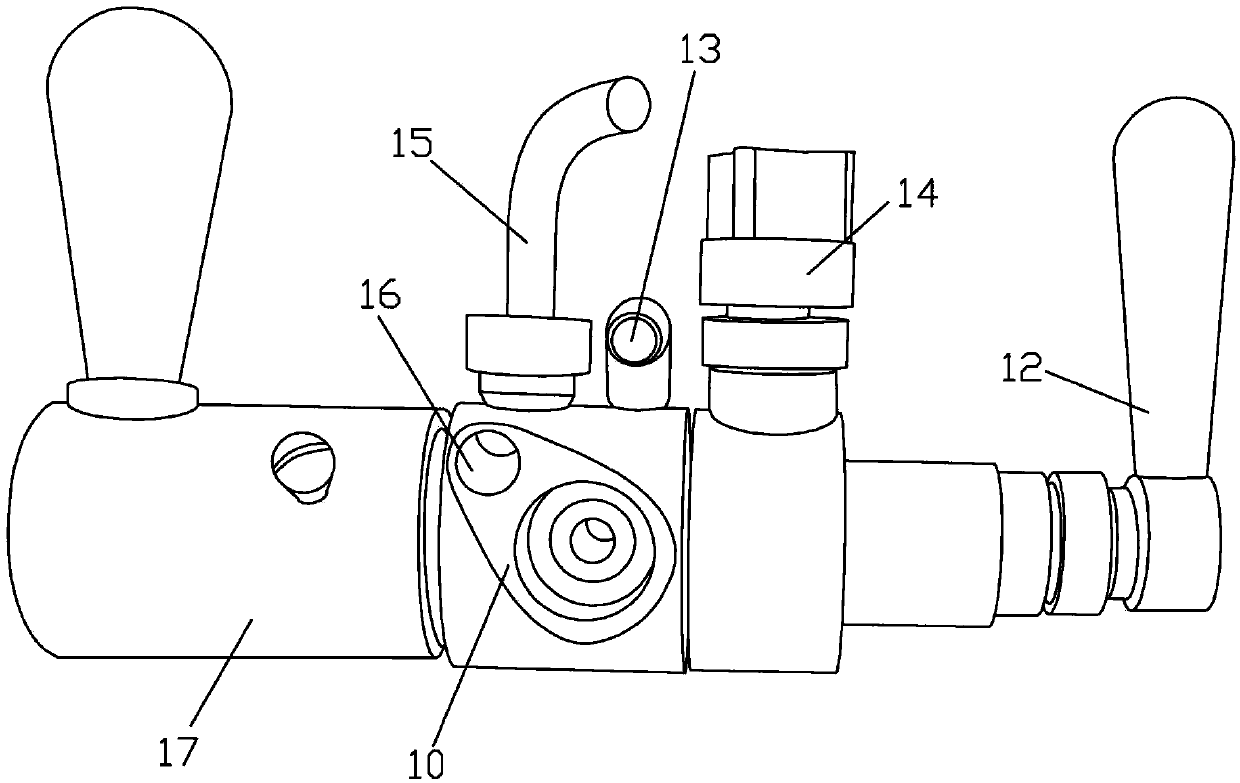

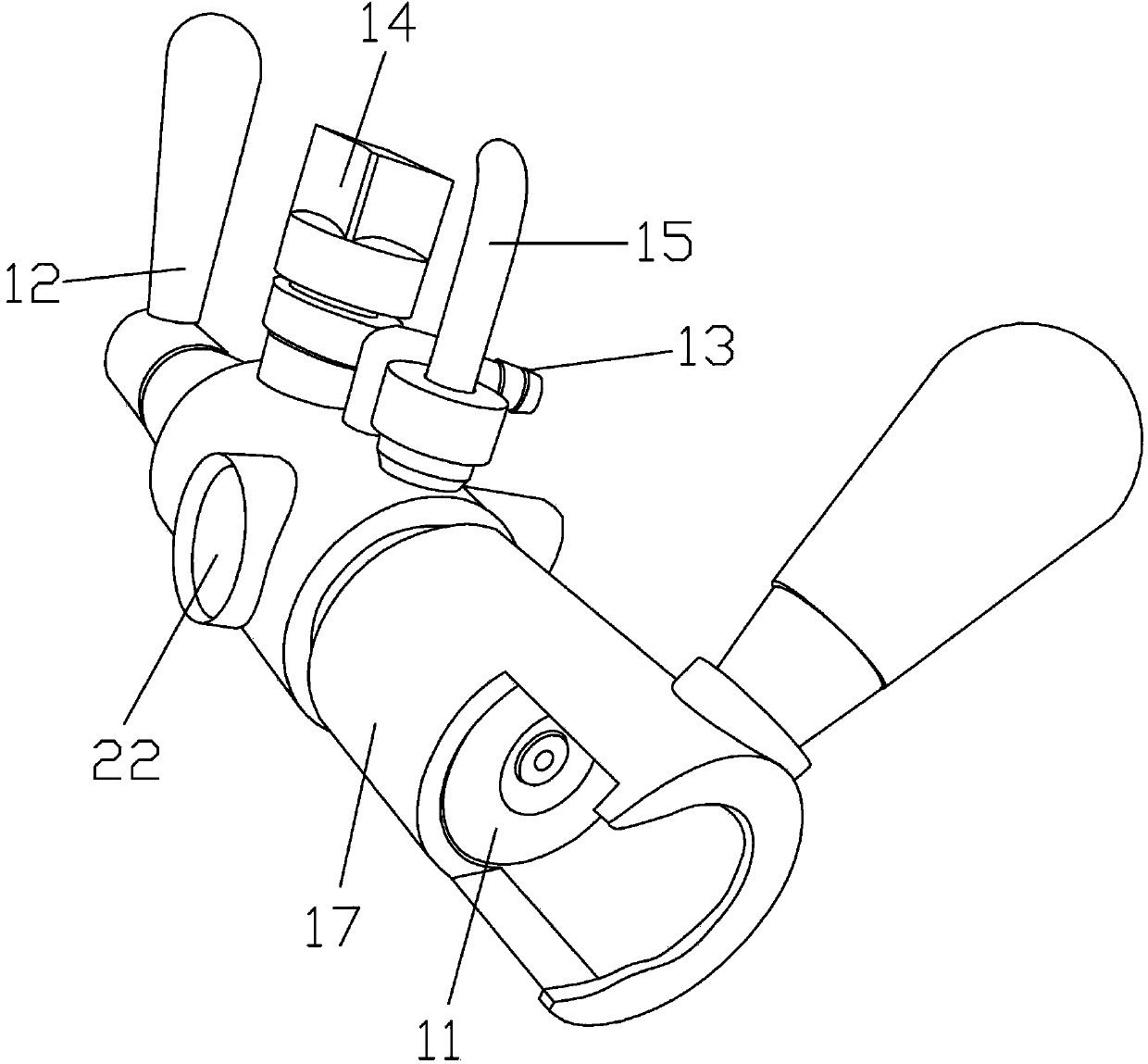

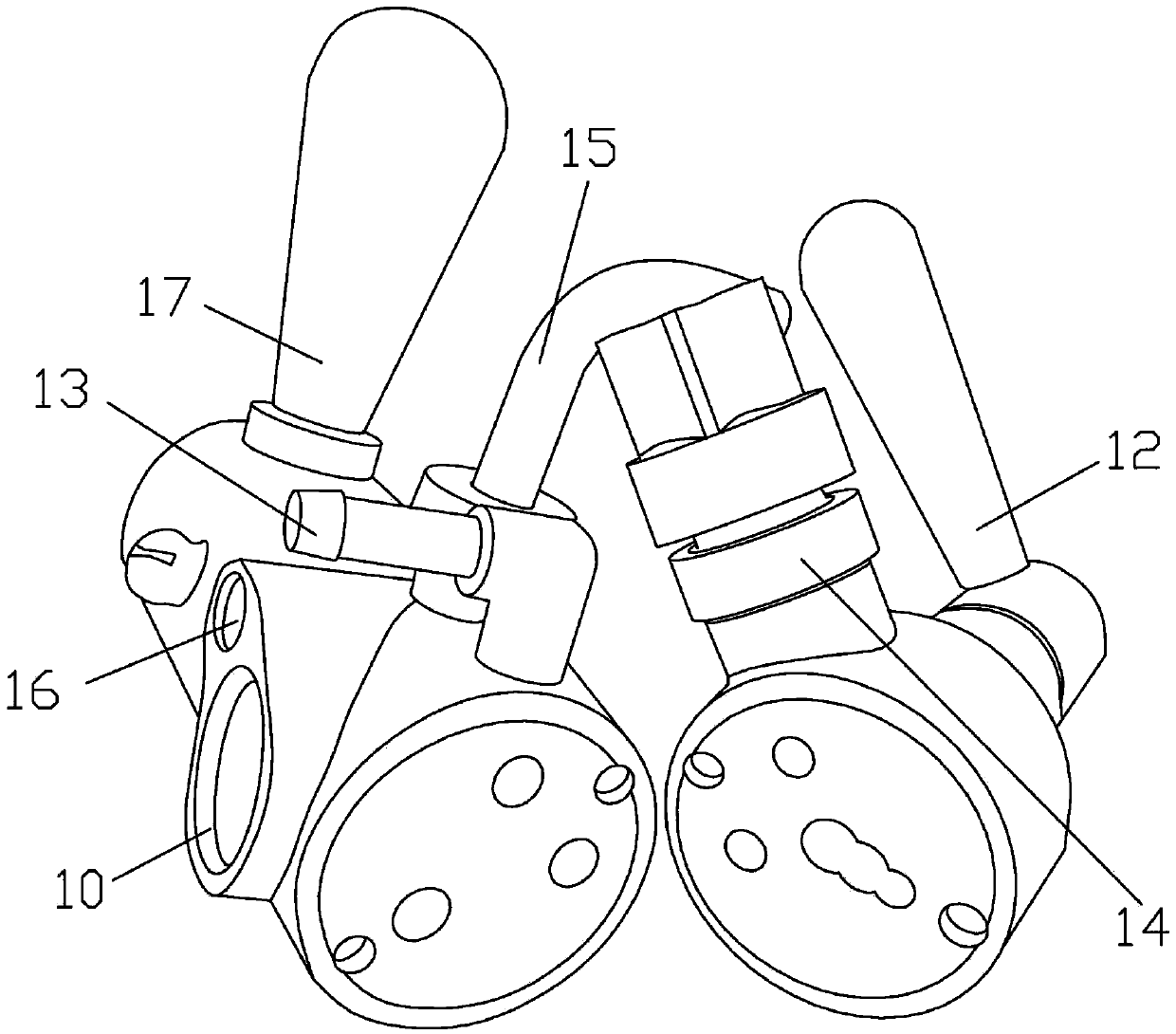

[0018] Below in conjunction with accompanying drawing, the present invention will be further described with specific embodiment, see figure 1 —4: Beer valve, including the valve body, in order to facilitate the processing of the wine inlet pipeline 18, the wine outlet pipeline 19, the inflation pipeline 20 and the exhaust pipeline 21, the valve body is divided into two parts, and the corresponding pipelines are processed respectively , to ensure that the pipes can be butted, and then fixedly connected by bolts, and a sealing gasket is arranged between the two separated parts of the valve body to prevent leakage. The valve body has a wine inlet connection seat 10, a wine outlet 11 and a switch valve 12. The inflation interface 13 and the control valve 14 are arranged on the outer surface of the valve body. When filling the bottle, carbon dioxide can be immediately charged and discharged. The air in the bottle can also prevent outside air from entering the bottle; the exhaust po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com